The physical structure of the axle-slash gears of the carrier

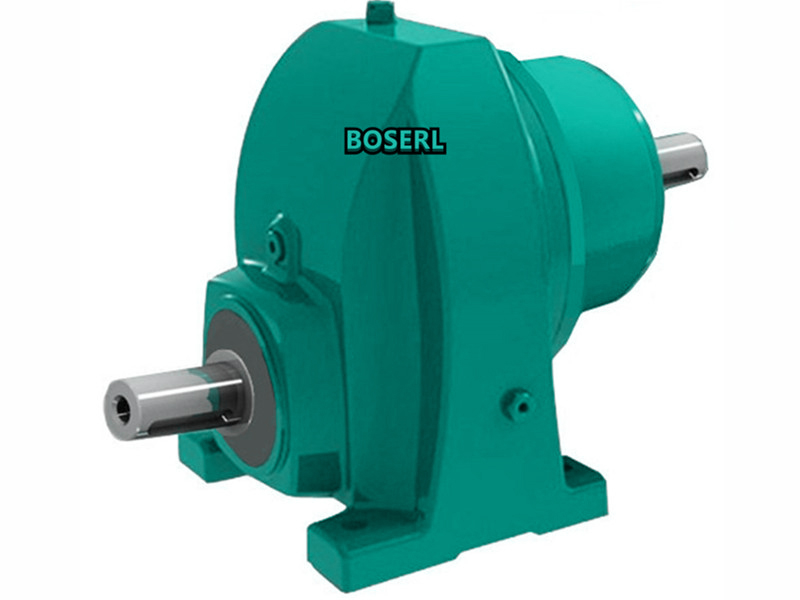

The physical structure of the co-axis-slash gear reduction machine. The impact of high- transmission belt systems can be severe. And you can do itStand-by gear brakesStructure design to prevent the scarring of roller material, e.g. Scratching in the direction of the roller 5-10 mm with a rigidity and intensity of content requirements, can also be used to reverse the tape design on the transport of back-way, especially for the delivery of sticky, sticky materials. Three factors should be taken into account in the design of the cono-sorted gear-reducing gear support frame transition. If the material scarring exceeds 10 mm, the transport belt is rendered more severe and even partially torn apart. Let us analyse the effect of the physical structure on the service life of the coaxial slash gear transport belt: the tether's twirl stretch [E] is 2.5-3.5 per cent, so that when the material scar is 10 mm high, the early wear and tear of 2 per cent of the abnormal congee rises is damaged. Equitable structural design is a pivotal factor in the useful life of the progressive conveyance belt, which is prone to early damage as a result of unfair structural design. It's a bad transition. It's a co-axisServo motor reducer(c) Severe wear and tear of the conveyor tape; excessive transition, which causes the failure of the conveyor belt folding into the head roller as a result of softening and falling rigidity, causing early damage to the belt; excessive malformation, where the conveyor belt is in the tail roller, in the middle of the turn, where the middle of the cross-section is easily visible, and prone to injury to the end of the funnel and early damage to the conveyor belt. However, if the material is scarred, which causes the local abnormal transformation of the conveyor belt, the local weariness of the conveyor belt is caused, as well as the early damage to the rubber surface of the roller。

the longer the shelf, the longer the straps of the same-axis slash gear, the longer the conveyor belt. at a height of 10 mm, the conveyor belt spreads around about 2 per cent of the abnormal deformation (which occurs locally) at a length of 1,000 mm in diameter. the transit area of the conveyance belt needs to be well designed for the transition. in the design of the roller ' s surface, the physical characteristics of the material are taken into account so that the material is less adhesive to the roller ' s surface and less easily scarred. the same axle gear must be used for transition design irregularitiesGeared motortransformation of the conveyor belt support frame. the co-axis slasher roller does not allow for the assembly of materials and the design of a material removal device. the life of the conveyance belt is measured in terms of exhaustion. there is therefore a need for a fair transition design. there have been many instances of the conveyor belt being torn apart by the impurities of the cargo. the transport belts of the same type produced by the plant ideally have the same rotational cycle, i.e. the same tiring life, but the actual life span is very different due to the different conditions of use, different design structures, and changing factors at the time of use, so we call it the useful life. for example... when the roller is scarred somewhere on the surface, an abnormal deformation of the same axle gear conveyor conveyor belts is carried out there. the fundamental ways to address the problem are: the quality of progressive goods and the elimination of impurities; the design of a funnel reproducing with due regard to the subject of tornification; and the technical retrofitting of the coaxial gear-reducing machine, the ability of the funnel to pass through the alien. for nylon tarpaulins, the break and stretch [e] is greater than the break and stretch of the wire kernel and the permitted material scar height. large band inside and outsideMotor gearedthe frequency of local tearing in the transmission system caused by roller stasis and snow stasis is high and should be highly visible. it is to minimize the wear and tear of the duct tape; second, the folding of the tape, which does not extend over a period of time; and third, the leaking of the material where the discharge is not. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The physical structure of the axle-slash gears of the carrier