Double-hole output of motor tank lubricants

Double-hole output of power-reducing tank lubricants. If the spring length does not match the delimitation, change the rotation spring length adjustment power rectangular. We'll have to adjust the left and right between the brakesRight-angle shaft reducer motorThe power-charger is free, and the revolving brake block adjusts the bolts to the left and right edges, so that the gap between the left and right two brake blocks and the brake wheel is equal, and is confirmed by measuring through the middle of the middle of the middle of the two-wall axis and the middle of the brake wheel. The electrodynamic hydraulic pusher brakes and the electromagnetic brakes are basically the same. Ka seriesreducing power sets are determined by the length of the brake spring. the brakes of the conic gear-retarder and the power-retrenchment block and the brake wheel are guaranteed by precise adjustments and have reached the appropriate size and equivalence of the two brake blocks with the brake wheel and the right power-retardation。

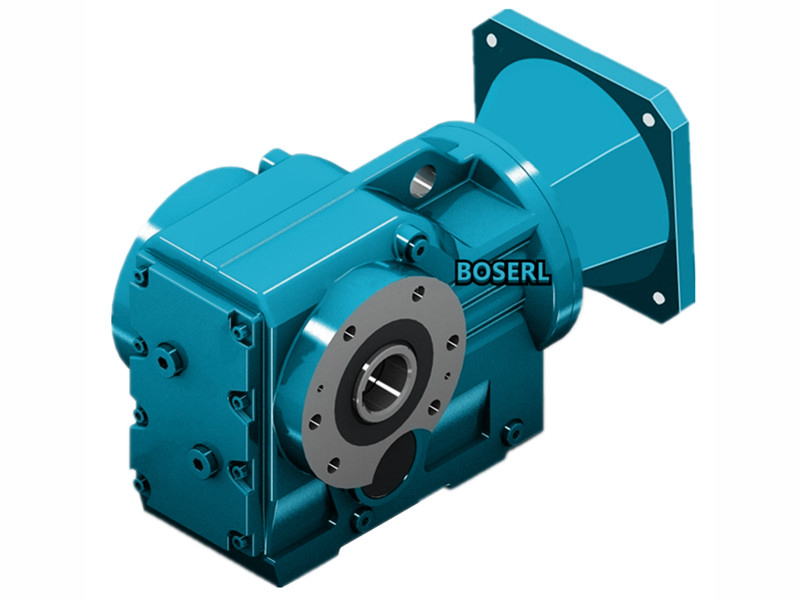

Ka-series transmissions, agenciesGeared motorIn the form of cylindrical gear brakes, conical gear brakes, planetary gear brakes, inner-lined needle brakes, etc., the main components are: boxes, gears, axes, bearings, planetary frames (in the case of planetary gear brakes) and inner-wire wheels (in the case of inline needles). Prosthetics are caused by the corrosive round and axle oscillations; poor cortex after wear on the side of the gear; failure of bearings; and damage to gears. The tank lubricant oil volume is within the limits of the scale of the oil, and the oil content is subject to a scheduled overhaul; the bearings with refuelling mouths are subject to a schedule of lubricant; no oil spills are permitted in the oil seals. Liquefied axles: seepage of fertilised alloys; leakage of oil from mechanical seals; oil quantity to be determined; flanche connection bolts not to be relaxed. Axes are the parts used to convey the twist. The difference is that the electric pusher brake can adjust the brake time, and the electromagnetic brake cannot adjust the brake time in a moment. Adjusts the upper-down gap of the brake block, the braker breaker state, and the rotation brake block adjusts the bolt to the lower-up gap to balance the gap between the upper and lower end of the block and the brake wheel。

The KA-seriesreducing machines are in the position of the brake shutter, adjusting the brake-trading process to the nut so that the sign line (B) on the top end of the indicator and on the brake arm is identical. Clockwise rotates the wheel, slows the brake time; reverses the clockwise rotates the wheel, faster the brake time. Day-to-day inspections of the various types of axes include the following: Flex-column . The rubber ring shall not be damaged or oil-contaminated; the semi-axis shall not have cracks; the semi-axis and axes shall not be rolling; and the rubber ring and the semi-axis no more than 2 mm. So, yeahMotor geared plus powerThe day-to-day maintenance of the spare parts and other accessories will be maintained in a manner consistent with common knowledge. The two axes are mainly linked to one another and they are rolled together, and there are three coaxal sections on the shipboarder: the flex-column-column-columb-column-column-column-column-column-column-column-column-column-column-column-column-column-columb-column-plumb-column-column-column-plumb-plum-plumb-plumb-plum-plum-plumb-plum-plumb-plum-plum-plum-plumb-plum-plumb-plum-plum-plum-press-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-plum-pop. The brake time is adjusted by adjusting the wheel by adjusting the size of the cone gear-reducingr plus the motor-publing wheel to the repo of the oil. (a) ka seriesreducing motor coxes: full lubrication should be provided at the joint axle; no oil spills and drops should be promised; no jumps should be promised; and the semi-axis should have no fatigue cracks, which can be struck with small hammers, which can be determined on the basis of the sound of knocks and leaching of oilSpiral cone gear deceleratorFifteen to 30 per cent of the loader ' s gear is worn more than the size of the original ruler and should be replaced. At work, the sound of the sound is subject to failure determination. The fever in the case, especially in the bearings, must not exceed the promised temperature rise when the KA series slow down. http://boserlgearreducer.com/product/list-kaxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Reluctance of the electric tank