Description of the configuration of the stand-by gear-discharge valve

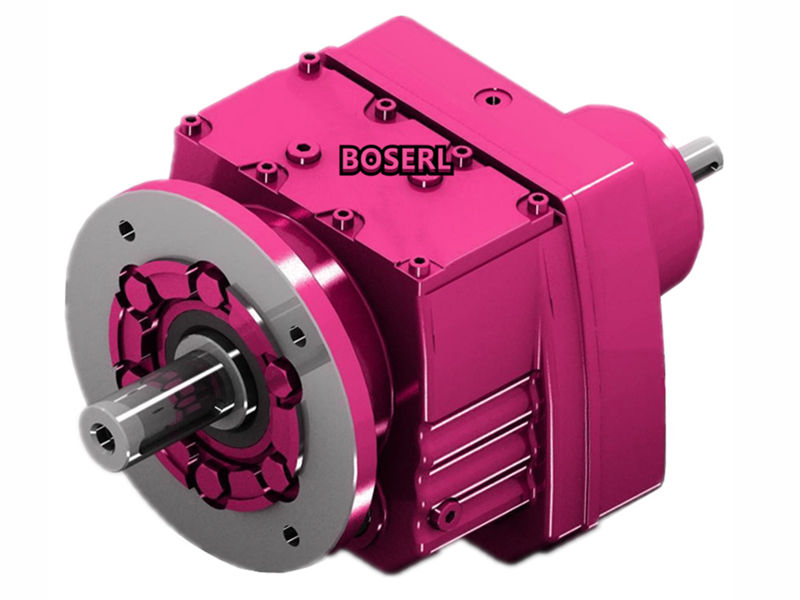

A description of the configuration of a standing gear-reducing motor off-pressure valve. If necessary, they also include indicators such as safety devices for de-pressure valves, detailed location of installation, inhalation characteristics, range of manoeuvres or homework, specified or promised use, acoustic pressure values, power requirements, in-house custody measures for high gearers, surface protection, paint cover, weight, etc. For the relevant safety devices and control equipment, please refer to the installation protocol and manual provided by the equipment manufacturer. Also, all points of the same cycle are equally spaced between the two branches of the axis, which can be checked using probes or instrumentation. Pay attention: For pumps with substrates (with grey-coated iron), make sure that the smelting surface is at the right level! For non-smuggling surfaces, the corresponding panels can also be corrected by means of fill sheets, provided they are easily adjusted (sliding). Unless a prior agreement is reached between the two parties, the gear will standGeared motorThe assembly of the pump shall ensure vertical proximity between the transfer axis and the subaxis. Note: Appropriate assembly tools should be used for assembly of axles. 5.3.2 Axes shield is assigned in accordance with the relevant classification for the prevention of an accident and can only be activated if it is fitted. A standing gear-reducing power plant series number consists of a contract number and a serial number and is directly etched on a stamp or pump body。

for example, the calibration of scratching axes that do not contain intermediate drums or gear rotations: the routing or axle error between the two sectors of the axle of a standing gear reduction engine does not promise to exceed 0.3 mm, and in a state of working temperature and supply pressure, it is also necessary to ensure that the above-mentioned error value is not exceeded for a standing gear reduction machine. the full type name of the stand-by gear-reducing motor is assigned in the technical parameter sheet or order confirmation. it's restartingMotor gearedWhen pumped, it is easy to extract it again from the fluid's “depositor” under normal conditions. A standing gear-reducing machine gear pump is used to pump lubricants, fuel and other lubricants. Installs the drive on the axis and locks it. Magnificent gear pumps shall be fitted to a finely processed franium cardiac ring. First, the medium of a standing gear-reducing motor pump must be clean and have good lubricating properties to ensure the proper operation of the gear pump, the high reliability and safety of the manoeuvre and the long-term useful life。

The installed gear pump at the bottom of the decompression valve with a standing gear reduction machine can only be installed at a precise level to avoid reversal. Reference is made to the installation protocols and manual of manipulation provided by the electric power plant. If we don't provide a joint axle shield (an express request from the ordering party), we'll be able to find outTurn frequency brakes slowing downOperators of the equipment must provide the corresponding coaxial hoods. Forced installation of the axle by the above method is prohibited, however, because of the damage to parts such as axes, gears, axle bearings, stopring rings and buttons, or so forth. To keep the mains of the pipe horizontally in order to retain as much fluid as possible in the pump when the pump is shut down. The liquid from the pump shall not contain any corrosive particles and shall not have the effect of chemical corrosion on the material of the pump. If the machine has to be coincidental, it has to be ensured that the machine is properly located and, if possible, by-stands or by-stands. For pumps with an out-of-axis expanse, it is necessary to remove the protective coating of the vertical gear-reducing engine (if possible with solvents and not sandpapers) from the vertical gear-reducing machine. If all points in the last round of the respective axis are equally spaced between the two axes of the axis, the fixed gear-reducing device has been identified and the point to be noticed is thatVertical reducerdifferent measure points must be scrolled by hand. the electrical connection of a standing gear-discharge valve must be completed by a qualified electrician in accordance with existing safety protocols. the application of the gear pumps referred to above covers all relevant oil pressure systems, from the lubrication system to the pure pump delivery. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Description of the configuration of the speed-reducing power off-pressure valve