A set of axle seals and a start-up

A set of axle seals and start. In the course of the above-mentioned replacements, the bearing parts of the pumps must also be inspected. Related maintenance work in axle seal is limited to non-scheduled check for leakage. The corresponding transfer may be checked by means of a point-motion transfer device, even if a low-, high-, high- slow-down generator pump set is fully loaded and the current valve is open. If possible, pump and inhaler pipes are filled with pumped lubricant, followed by exhaust work. The link to the filling ring or the cross-section of the block must be staggered at about 90°Servo motor reducerA set of interfaces must be located in the section of the filling ring behind the uncapped back. The axle seal was promised to have a very small leakage. A large-size pump of a low- high- rectangularretractioner usually carries a ring bolt and is used for a fixed hanger at the end of the shell, while a small-size pump of a low- high- rectangler is left with a screwdriver. Based on the design details, the gargle bolt can be placed blind at the head. The following scenario, either in a hole or in a screwdriver, provides options for refuelling or exhausting the corresponding pump. In the event of an increase in leaks from the above-mentioned low-, large-, high-, high-, high-, low-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high-, high- power plant. Axle seals do not require any maintenance work. Prior to the start-up of a set of low-, large-twirl-reducing electric power pumps, the inhaled pipe would be filled with the medium from which it was pumped, especially in the face of bad suction (to avoid a lack of lubrication of the pumps). In general, there is no need to replace the entire filling box component. Before starting a set of low- high- twisters, the installation of the pump must be checked to ensure that the pump meets the sequence of manipulation specified in the appropriate technical information. The gear pump is a self-suction pump. If the pump is launched in the opposite direction, it would cause the axle seal to become hazardous and lead to leakage. Pumps suitable for clockwise and reverse-clockwise rotation are not within the limits specified above. And then you can spin low-, big-twirlGeared motorSets a threaded liner/scaling method to set the opening pressure required. If it is no longer possible to tighten a nut on the hood of a set of filling tanks, an additional filling ring must be installed。

The pressured nut in a low-, large--retrieval electric unit of a filling box can be tightened only slightly to allow for a light leakage of the fillings during the operation of the machine, thus facilitating the diffusion of the heat generated by friction. For electric gear pumps, the corresponding electrical connection can only be performed by a qualified electrician. Under normal conditions, the pump imports and transmits the air within the inhaled tube path to the export route. If the open pressure of the off-pressure valve needs to be adjusted/adjusted, follow the following steps: Open the pressure end cap and wrinkle the locks. Check the corresponding shift. Before initial commissioning, it is necessary to ensure that sufficient media are available in the pump. WillTurn frequency brakes slowing downA set of all other additional connections (e.g. for sealing or cleaning fluids) is fully open and the corresponding flow is checked. Reload the pressure cover (don't forget to put the seal on). Clockwise rotation: Progress opens pressure; Counterclockwise rotates: lowers open pressure. Pumps are strictly prohibited from operating without lubrication. If a stop-valve is installed on the inhaling or export route, the valve must be fully opened. Warning. Physical security protection devices (e.g., axes and belts) must be installed. A low-, big-twirlreducing generator sets each pump with an arrow indicating a shift. If there is a real need to update a set of filling box components for the low-, high- twister-retarder, the axial bearings and sealed silent rings must be checked. In the event of leakage, replacement is necessary. Care must be taken to break the filling ring along the axis and in the direction of the path, so that the ring can flow to and from the axis. If there are significant scratches on the axis, the axis must be replaced, otherwise the sealing of the new filling ring will be affected. Recommended pressure set value: approximately 10 per cent higher than the working/operational pressure of the system. YesGear reducer and gearboxafter a long run, if the leakage rate is too high, the nut on the pressure cap of the filling tank can be tightened (i.e., rotated by one-sixth round) and then checked for the extent of the leakage. http://boserlgearreducer.com/product/list-sfxiliejiansuji-cn.html

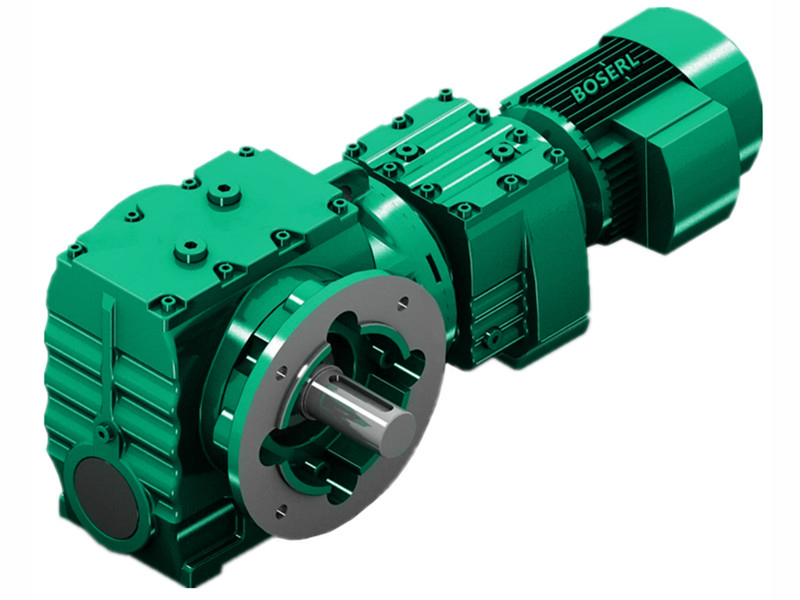

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A set of axle seals and a start-up