Level 3 oscillating parasol gears are used in the middle of the desert Bahrain

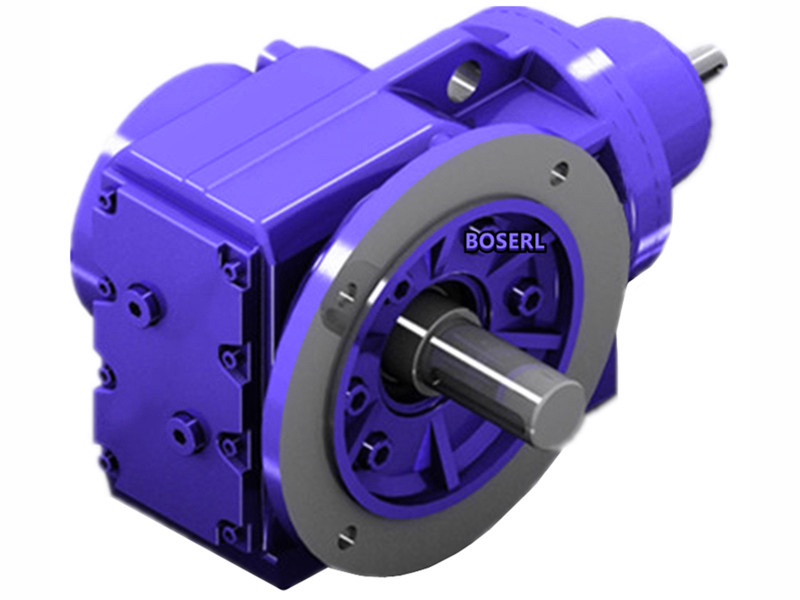

The third-stage parasol gear-reducing power plant is used in the middle of the desert bahrain. The annual production of iron and steel is about 600,000 tons, which represents one sixth of all previous beams and material imports throughout the middle east. Plants are required to design a certain number of three-stage slash-pattern gear-retarders to adapt to the typical load-back of the roller, in particular the s5 intermittent and non-cyclical loads, changes in and frequent overloading of s9. boserl has been working with the mill manufacturer for more than a decade on a number of projects, boserl level 3Stand-by gear brakesProvides a generic driver solution for the steel and metal industries, ranging from a whirlwind table to a cooling bed, from cutting wires to steel packs to other sectors of the production process. Four high-twirl-resort industrial gears, which are used to correct the heavy fury in front of the shrubs, are equipped with input and output axes on both sides and can be manipulated at will. The driver system provided by the boserl-iii slasher is very strong: in a single shell, gears with slashed and refined carvings on a strict scale are excellent in a non-controversial manner even under the high-range and axle load. Special synthetic lubricant (isovg220) and special coatings are provided to adapt to very real conditions and working temperatures. In addition to more than 600 gill driveers, the roller uses other boserl systems. in the iron and steel plant project, reversible rollers in bahrain use stick driveers and many boserlsSpeed-down powerDrive solutions, including large industrial gears in the calibrated machines used for motor vehicles. these systems, because of their stringent functional requirements under harsh conditions, are flexible, integrated casings that ensure a long useful life, high-quality gears that are accurately processed by boserl gears, and design flexibility, such as optional axes for both sides。

In Bahrain ' s roller, the challenge of reliable driving: heavy loads, frequent and intense shock, very real temperature. The engineering firm is determined to limit the special gear solution to a minimum and therefore needs to use as many measures as possible to implement the full product set of gears. A leader of heavy machinery in the steel and metal industries focuses on casting technology, long-finery plants, plumbing plants, casting plants, non-ferrous metal plants and thermal treatment technology in steel factories. Finally, a roller manufacturer requires a particularly high degree of flexibility when used on many specific driver systems. As a component of the plant, the equipment engineering specialists in the steel industry designed and installed heavy rollers with the most advanced forebears. In addition, tremors-mitigated shell materials can be selected to help reduce the impact of the violent movement of audibles. Many of the drives installed along these stations have to deal with mammogram acceleration andGear with motorand impact. Greater elasticity and durability are options through the use of enhanced axial materials (e.g. 42CrMo4) and more robust bearings. Sixteen tons of beams passed through a reversible roller. These include parallel-axis gear brakes for cooling bed chain carriers, where they replace the special gear previously required for such applications, as the weather in the Gulf States exposes Sid's wheel drive to particularly high ambient temperatures. The roller system also requires other high-resilient and robust drive solutions for other machines, such as a two-support wheel-based orthogonal for hydraulic regulation. For these industrial gears, special output axes with suitable poachers are equipped with the required encoder. In recent years, a large integrated steel plant has been built in the Al-Shid industrial area of the Kingdom of Bahrain. Boserl designed for the rollerPower-carrying brakesthe driver system provides a robust and flexible solution. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Slower power is used in the middle of the desert in Bahrain