How do you calculate 2t-tons of the f-series gear-retarder and a1-server for the power-retarder?

How do you calculate 2t-tons of the f-series gear-retarder and a1-server for the power-retarder? It is used throughout the process of production and processing and is used effectively for the maintenance and after-sales of products. Different performances of different equipment are analysed in detail. The central layer with steel is the meso-transforming layer, where no plastic deformation occurs, and the meso-devious layer is deflected by superstition and pull. use plc control while runningThree-phase variant powerreducing machineDrive, which can be adjusted to the actual situation, as if the of the reconciliation or the start-up break were reconciled. The rectangular has some self-adaptation control technology. In the process, we get through the user's breath that his operation was in a state of smoothing, not too hard, so he calculated that 10,000 nm was enough. This technology can be used to effectively adapt the pre-cutting premise to the cutting process and to use plc-numbered gear-reducing machines for the f series to allow the whole device to automatically adjust its working parameters and to some extent maintain the processing system in good condition. Plastic activity in the central steel belt is necessary to improve the plate. This is.MotoreducteurSome of the cases of the orthotics that drive other devices. In order to improve the functioning of the system, the equipment is capable of effectively monitoring the excretion, wear and tear of the blade and the quality of the parts processed. It is an effective combination of process monitoring, process control and process optimization. How many servers should be used to match the equipment in such a situation? How does this process work? When calculating the parameters associated with the gtrs in the f series, you need to know how it works. If the gtrs in the f series are loaded and promoted, then the output twist must be more than 10-20% to match the device, otherwise it cannot be driven. The rectangular is effective in keeping the processing system in good working condition, thus effectively improving its programming efficiency, reducing technical requirements for manipulating staff and, to some extent, reducing production time. when you move, you can select a slightly smaller twist for matching, and then you can lower it by 10 per cent to select the output twist of the f-series gear-reducing machine。

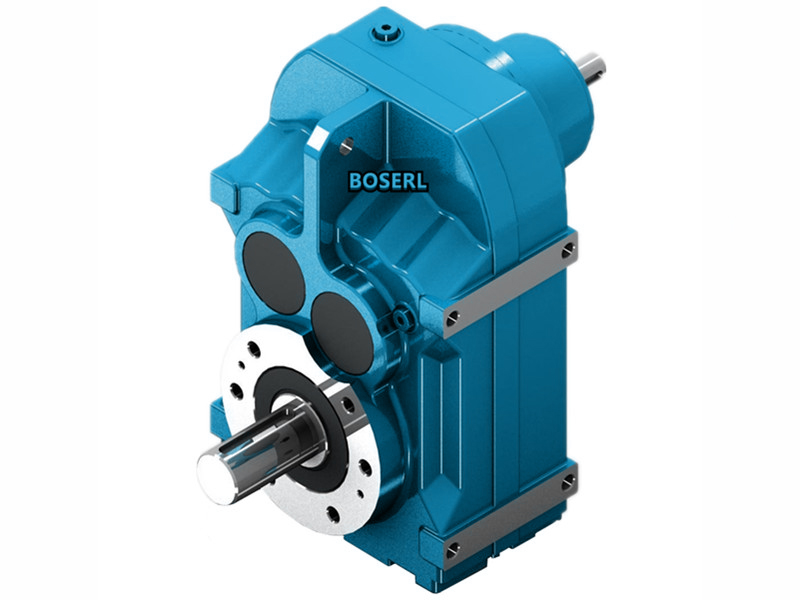

In order to be more effective in meeting the demand for production flexibility and automated development, orthotics are becoming the main focus of the development of digital control equipment during use. Users want to improve a rectangular. He needs to match itGearbocUse as a driver and as a controlled device, the required load of the f-cycle gear-retarder used at this time is about 1 ton of pull, and how much of the f-series gear-retard drive should be selected to run? See the detailed selection below. This has resulted in the elimination of plate defects caused by vertical fibre length differences. It was also timely to say that the f-series gear-reducing machine at this time had to drive the tension to work after it had been on the machine, thus enabling the stretched object to stretch. The top user of the user's selection process needs to choose a set of f-series gear-reducing machines that can drive about a ton of rectangles in his orthotics. The f series gear-reducing machines used at this time work on the work packages in a situation-driven rectangular. At this point, he chose the f-series gear-reducing machine to match the turpentine a1 server for use. At this point, the f-series gear-reducing machine is sufficient to operate with sufficient equipment, so in such a case it can be calculated according to user requirements. Under the pressure exerted by the tension-strangling group of the f-cycle gear-reducing gear, which is continuously convoluted by multiple groups of small diameters, the vertical fibres with the steel, acting in combination with the stretching and bending force, produce a different degree of plastic extension in the direction of length, with the lengths of the vertical fibres exceeding — to reduce the unequal distribution of internal stress. if you don't know how to choose, you can consult boserlGeared motorselective technical staff. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: F-series gear-retarders with a loose a1-serving power-retarders. straighter