How should speed-reducing machines of up to 1,500 nms be selected by 750 w tilt gears and electrics in food machine rollers?

How should the slasher type be selected for a 750w tilt gear brake with an electric power of 1,500nm in a food machine roller? At this point in time, the user needs to choose - the slasher to drive the matching. passed 750wGearbocThe scroll-axis transfer connection has a moving structure to drive the roller. The transmission structure includes axles, gears, bearings and support seats. So this machine is often processed with food. What is the type of slasher that should be chosen at this time to meet user needs? Let's look at the roller's structure and what to look at when choosing. The support is fixed to the top of the base, the bearings are installed on the upper side of the support, the gears are fixed on the right side of the moving axis, and the left side of the moving axis is fixed through the bearings and the rolling axis of the reduction engine. Each wheel can be installed in the upper of the respective substations in a rolling manner, the circle of each wheel corresponds to the outer circle of the roller, and the slasher is fixed to the left of the top of the base, thereducing machine is located between the roller and the base, and the converse of the motor is directed to the right. This is some of the detailed usage by users. The user-modified machine is well designed, structured, and operates the engine-enabled transmission axis and gear rolling in a slant gear-reducing sample, while the gear-coated rodent drives the wheel backwards. The device was operated while Xua searched for a power to drive him to work. The tastes after processing through food machine rollers are more consistent with daily dietary needs. No details were selected at this time because no detailed was determinedTurn frequency brakes slowing downThe only two parameters that currently match his equipment length for use in the parameters provided by the user are those that can be used to select the corresponding slasher, but the of the operation is uncertain, so it is not easy to select the corresponding decelerator model for use on the equipment。

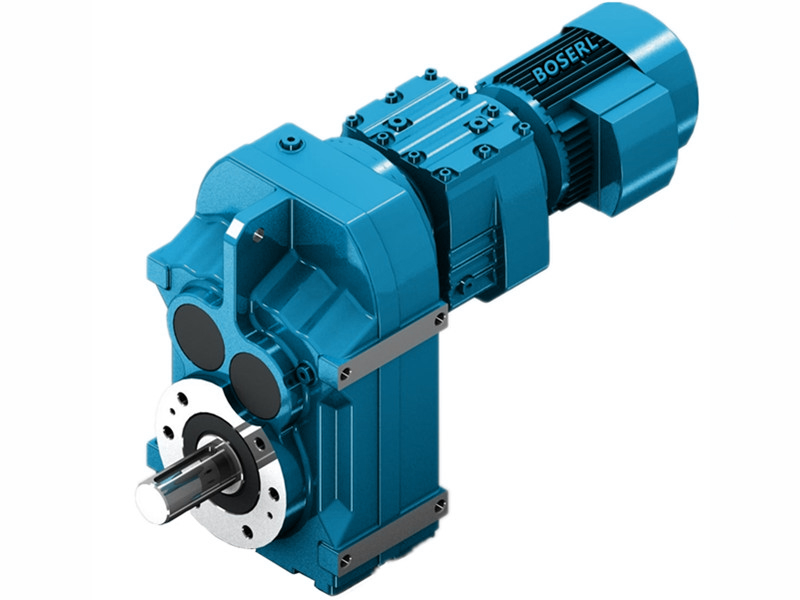

The food roller is a common device for food processing, which enables the food to be fully modulated and the spices, such as spices and sauce, to be fully modulated and the food to taste as a processing machine. and use 750 wGeared motorThe operation of the driving roller agencies makes the material that needs to be handled constantly rolling in the process. The other electric-enabled axle rolls, and the moving axle drives four sets of mixers and spinal blades at the same time, pouring into the generation to process food and mix it. After the food is gleaned at the right end of the axle, the right-hand horn of the steering trough is able to lift up the food, rotate the roller, and rotate it, which in turn can throw the food back to the left side of the roller, and then the food is returned to the mixer, so that the food is mixed back and forth, to the extent that the food is sufficiently twitched for the food to be processed. The user ' s roller is made up of the base, roller, tilt gear-retarder electric, roller and returner structures. Existing rollers are often used in a way that is not sufficiently convoluted to the extent that the food to be processed is mixed in a roller. The roller is located directly above the base, and there are four support-oriented structures between the roller and the top of the base. This is some of the details of the motor tilt gear brakes used by the user ' s food roller and some of the structure of the user ' s equipment. The outside perimeter of the roller has a ring of teeth bound to the gear rod, and the tilt gear brake is placed on the right-left side of the roller, which is fixed on the upper side of the base seat through a frame, and the tilt gear brake is located below the second power. His request was to use 750 w of an oscillator that could reach 1,500 nm. at this point, you can choose to determine whether to use an oscillator or notGs snail scalding machine, then the type is determined, and then the simplistic choice of the corresponding slasher. during the mixing, the spiral blades slowly push food from the mixer pole to the right end of the moving bullet axis, while the rolling direction of the roller is the opposite of that of the rotor of the first generator, making the rolling direction of the roller the opposite of that of the moving bullet axis. http://boserlgearreducer.com/product/list-fxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: 750 w tilt gear brakes and electrics up to 1,500 nm in food machine rollers