R-series speed-reducing accuracy analysis

R-seriesreducing accuracy analysis. The basic accuracy and error theory of the r series ofreducing machines was elaborated, the research methodology for the r series ofreducing machines was first explored, and recommendations were made for a project to assess the error of the line-shaping plate of the same axle gears. even if a steel ball cannot be in contact with the inner and outer troughs at 4 o'clock, it is completely impossible for a steel ball like this to spread across four points at the same timeGearbocRide side gap is zero. The co-structure of the side-lined r series ofreducing machines determines the movement to be a sideless condensation and therefore the movement has no back differential transmission. (b) the mechanical transport of the axle gear reduction machine is defined as the rotational lag of the r series decelerator output axis during the subsequent reverse rotation when the input axis begins to reverse. The four-point contact between each steel ball and the inside and outside line-blocking slots is carried by the end-lined r series of reduction machines. analyses the transmission error sources ofout output institutions, such as the axle gear-reducing machines, analyses the size of the calculation of motion error using the equivalent body research method, and establishes mathematical models for emitout-motion error。

Equivalent cargoreducing machine error analysis: study and analysis of the structure of several of the equalout bodies and their aerodynamics, discussion of the structure design of the zero zero zero zero zero zero zero zero zero, and selection of the steel ball-sink zero zero zero for the r seriesreducing machine. The establishment of the agency's combined motion error calculation, using the probability statistical method of the error evaluation principle to identify the signature of the moving error distribution and to arrive at the probability statistical calculation of the agency's moving accuracy. using matlab software programming to draw a curve map of the carving error with the error of the structural parameters, to get the r-series axle gear brakeGeared motorAn error in the scrotum structure parameter affects the pattern of the denture error, which allows control of the deviation of the structural parameter that affects the greater denture error in the design processing. Whether the active eccentric axis is positive or the reverse rolling, the co-brand is zero, while the simultaneous contact at four points is assured by a mechanism for intervalidation. The main reason for the regression of the coaxial slasher is the condensation of the diaphragm and the elastic deformation of the drive。

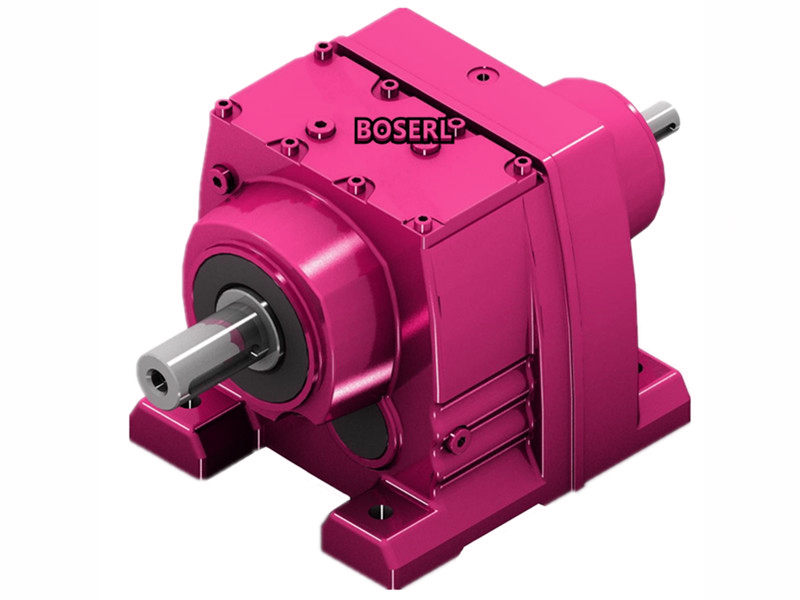

In the form of structural sketches, study and analysis of the principles of theout output structure of the two r series ofreducing machines, the contours of the steel plume at the end of the steel ball, and the contours of the contours at the end of the ball. based on the results of previous researchHorizontal reducerThe transporter's lactation machine proceeded to determine the origin of the carving error of the main component of the waver, the coaxal tilt gear reductionr, through an analysis of the curvature processing method. An analytical study of the main structural parameters that influence the contours is conducted to calculate the coding teeth error using the derived contours equation. The resonance of the axle gear is expected to have a severe effect on the moving accuracy of the machine, particularly the precision machine, which is highly active and reverse, and is therefore a very important functional indicator parameter in the mechanical movement. An analysis of the transmission principles for the velocity change of the co-axis slash gear-reducing motors of the steel plume and the steel ball cycling plume condensers. The full text is divided into five sectors, as follows: analysis of the kinetic accuracy of the r series ofreducing machines: analysis of the sources of error affecting the kinetic accuracy of the volleyball planetary electric agency; analysis of the formation of kinetic error from the processing methods and processes of various components, such as palletettes; and linking to the error in the manufacturing of axle gear-reducing machines; and the passivity. discussion of the status, progress and trends of internal and external studies of the r series of low-tooth reduction machines and the movement of active teeth, and analysis of end-end condensationMotor gearedThe significance of the motion accuracy requirement in the context of and practical application of the theoretical studies of electrical institutions. An analysis of the transmission accuracy of R-seriesreducing machines. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-delaying accuracy analysis