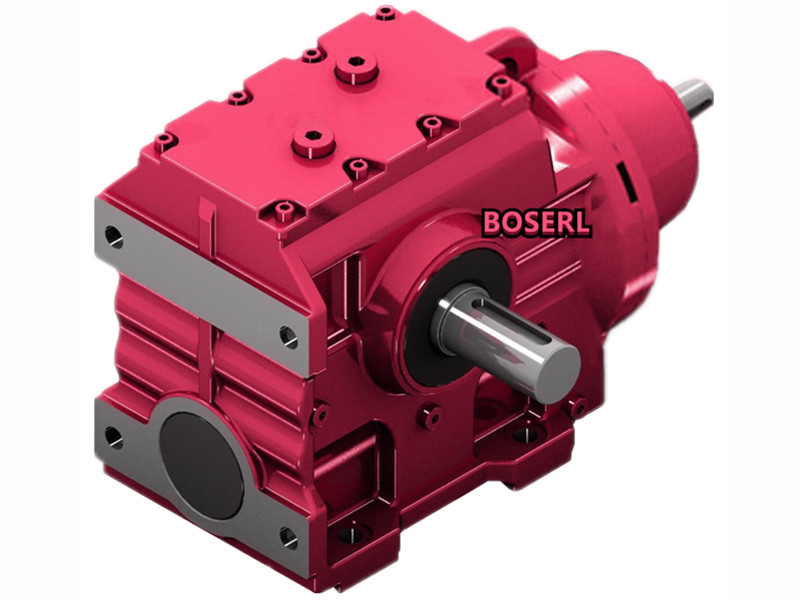

S-series gear analysis

S-s-s-s-s-s-s-s-s-s-s. Wire palsing is an important component of the s series ofreducing machines, and their processing should primarily control their process deviations. The so-called line of action of the s seriesreducing machines is the point at which the sub-components of the movement interact with each moment and the direction of the force. The denture deviation will affect the vibrations and shocks of the steel ball as it moves in the plume, thus affecting the smoothness of the movement, which can be used as an error item to measure the smoothness of the transfer movement. it reflects a deviation between the actual and the design contours of the palette, and can serve as an error item to measure the smoothness of the palette。Big-rate slow-down machineGear synthesis error: the method of spacing the equidistance curves of the two near-designed contours that are inclusive of the actual contours on the end of the line, within the full contours. The s seriesreducing machines are defined as follows: a double-applied calculation of the various sub-agencies that make up complex bodies can be derived from the analysis of the s seriesreducing machine agency error. accumulation error in the gear range of the s series of brakes: the large difference between the actual arc length and the arc length in any two of the same sides of the gear on a scale line gear。

S-s-s-s-s-s-s-s-s-s-s-sGeared motorA large difference between the actual arc length and the common arc length of the two adjacent to the same arc in an even circle of line gears. Therefore, the analysis of the movement error of the various original errors can be done by analysing the dynamic direction between the s-seriesreducing device links and by creating an agency motion error analysis model at a point on the output component, as well as by performing a moving error analysis. Thus, an application to each sub-organism can calculate the movement error of the sub-organism from the actionr and also from the initiative of the next sub-organism. The error analysis of the s seriesreducing machine is based primarily on the error source of the drive, and studies are conducted on the original error source, such as the parameter error, the size error, the motion side gap, and the tilt of the motion side axis. These original errors caused the s series ofreducing machines to cause local motion errors of a very different size, i. E. , the size of the agency's drive error is related not only to the magnitude of the original error, but also to the agency's movement. the denture combined error examination examined the size of the error at the point of the whole dent, which is a combination of error factors during the processing of the pallet and is therefore availableServo motor reducerThe combined error of the palleting drive is used as an error item to measure the correctness of the transfer movement。

S-reducing machine tooth error: the method of spacing the equidistance curves of the two near-design gears that are inclusive of the actual dents, on the end of the s-reducing machine, within a single dent. It is clear from the rationale of the function line incremental method that the transmission of the original error and the transmission of the institutional strength and movement need to be carried by the action line. It is used to measure the correctness of s-seriesreducing machines. From this point of view, a mathematical model of the agency's error analysis can be created. yesHelical-worm gearmotorA complex structure consisting of multiple components or a series of simple institutions, depending on how the institution is connected and moved in detail, S-series reduction machines can usually be broken down into a combination of simple institutions. A simple body or a “constructor group” comprising complex institutions is referred to as a sub-organism. The function line increment method is to study the process of transmission of the original error and its transfer equation during the transmission from the institutional movement, thus extracting the agency ' s motion error. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: S-series gear analysis