Auto-lock speed-reducing applications and failure forms

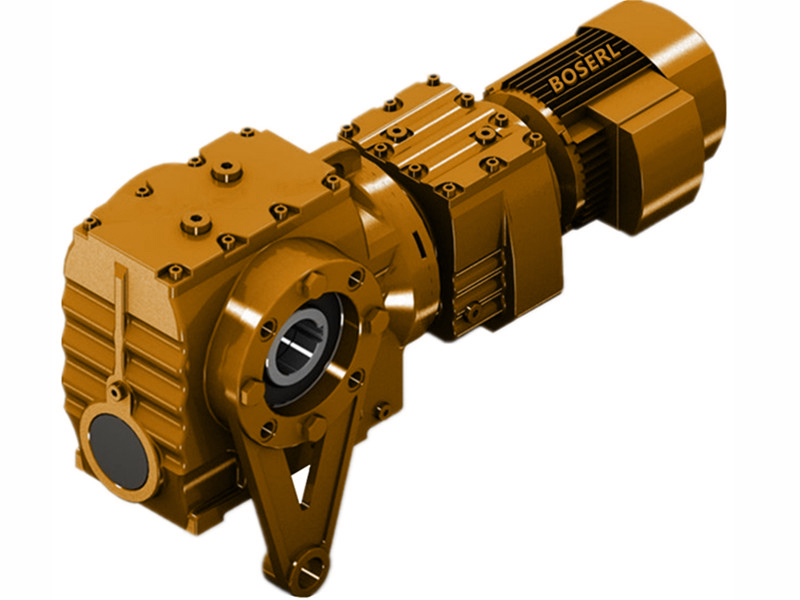

Self-lockretarding application and failure form. Snails are made of carbon steel or alloy steel and spiral surfaces should be heat-treated (e. G. , gillfire and carbon seepage) to achieve high hardness (hrc45-63); the carrying capacity is then carried by grinding or grinding to progress. Snails are often used in two-axis staggering, high-motion, low-power transmission or intermittent work. Snails are used to transfer motion and power between the staggered axes. our b0serl developed a moving form, except for our own lockGeared motorit is also widely used in machine beds, cars, instruments, metallurgical machines and other machines or equipment, as it can be promoted as a result of reduced energy consumption through the use of wheel-axis. so we're not just good at lock-downs, but, more broadly, we're trying to build up something that's the most sophisticated in the mechanical industry. snail teeth are not easily damaged and therefore do not normally have to be measured for their strength, but the strength and strength of the snail axis should be measured when necessary. in addition, because of the self-locking nature of the movement when it is smaller in y1, it is commonly used to provide security protection in cranes such as rollers. to avoid adhesion and wear-mitigation, snail-carrying materials need to be equipped with decomposition, milling and adhesive. comprehensive: for cast iron and small-diameter copper snails。Induction Motor 3PhMost of the snails are made of copper, which is not important for low- movements, and sometimes is also made of brass or cast iron。

Today, I would like to share with you some of the topics on which his motion-making applications, which often occur in production applications, what forms of invalidity, what causes of invalidity, etc., and how his motion-making is applied, which are then taken into account。Micro move motorThe tooth-exposure stress is an important factor in corrosive geling and wear, so it is still the basic calculation for snail movement based on the tooth-exposure intensity. The snails are structured in three forms. In order to prevent adhesive and wear-mitigation, self-lock-reducing machines should choose a good way of lubricating and lubricating oils with anti-gel additives. However, as snails are less efficient in moving, they are more smooth, and they have easy fever, etc. , adhesive and wear and tear damage are more common. There is not yet a mature method of calculating snail transfer glue and wear. If the thermal balance calculation fails to satisfy the requirements, the projectile is added to the outer side of the box or a forced cooling device is used. Thermally balanced calculations should also be performed for the closed-circuit movement. Gymbolic pressure formula: round rims are cast iron or steel, and the rims are copper. The self-locking retrenchor is carried by the snail, which has a bit of abrasion, wear, glue and bending. Z1 = 2 ~ 4 is often used to drive efficiency for progress when it is required to transmit greater power. A bolt-linking system: the rims and rims use ammonium perforation, which is connected with bolts, and the scalding of a self-lock-reducing machine, which is a structure that transfers motion and power between the two axes at a staggered space, with the horns between the two axes being available for any value, which is commonly used at 90°. in addition, the bending strength of the gear should sometimes be measured。Gear reducer and gearboxsnails and axes, called snails. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-delaying applications