Three major problems are common in a self-locker

Three main problems are common in self-locking. Solutions: Ensure quality of assembly. In order to ensure the quality of the assembly, the plant purchased and built specialized tools to remove and install components such as self-lock-reducing snails, snails, bearings, gears, etc., so as to avoid, to the extent possible, direct banging with other tools, such as hammers; to replace gears, self-locks, as far as possible, with original plant parts and pairs; and to assemble the output axis, with regard to the public connection, D<50mm, using h7 k6=" d = ">50mm, using H7/m6 with anti-adhesive or red-dane oil to protect the hollow axis from wear and tear, to prevent cortex from being used for maintenance. When you refuel, keep an eye on the amount of oil and the locationSpeed-down powerGet accurate lubrication. In general, the wear and tear are slow, as is the case in a factory where some of the self-locking brake machines can be used for more than 10 years. In the event of faster wear and tear on a self-locking retrenchor, consideration is given to the accuracy of the retrenchor ' s selection, overloading, self-locked material, assembly quality or use of the environment. HRC 4555, which is also commonly used to 40C: hard HRC 5055, grinding through a snail grinding bed to a calf scale of Ra0.8 fcm, and when thereducing machine is operational, the snail is like a “scratch” of the snail, which is cut down and wears the snails. The main reasons for this are four points, the fair mix of self-retardation materials, the surface quality of the rubbed, the choice of lubricant, the accuracy of the additions, and the quality of assembly and use of the environment. Self-lock/snailretarder wears: cascadron is used as a self-lock-retarder snail, 45 steel snails are used as snail material, self-lockSecond-stage brakesFever and oil spills: Self-lock-reducing machines use non-ferrous metals as snails in order to improve efficiency, while snails use hard steel because they are smoother frictions that generate higher heat during their operation, with a difference in thermal expansion between the parts and seals of the self-restrictor, thus creating a gap between the interfaces, while the fluids are easily leaking as the temperature rises。

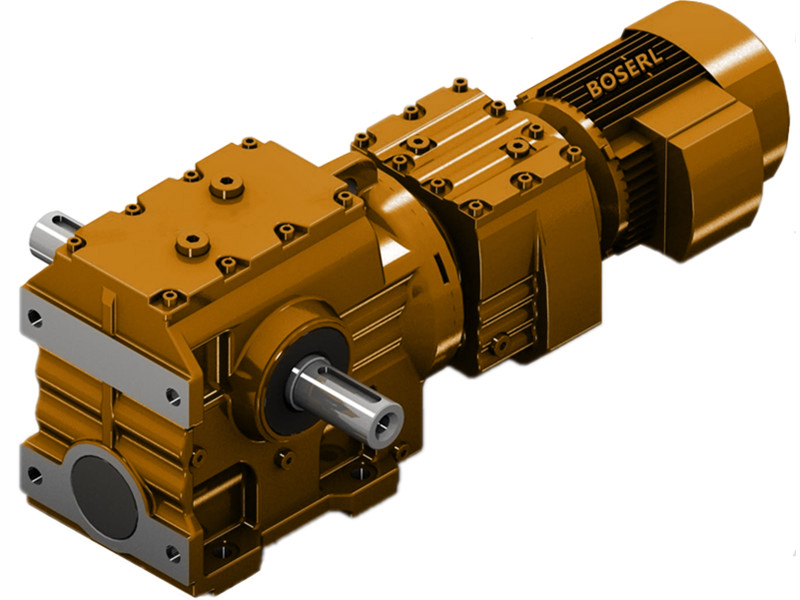

The additives also contain seal-ring regulators and leak-resistant agents, which keep the seals soft and flexible and effectively reduce lubricant spills. Let's find out about the lockElectric brakesThere are three common topics, all of which are common and can be solved by maintenance, some of which are for a self-locker, so don't worry about the quality of our b0serl product. Self-locked scalder brake bearings are damaged: even when the self-locked respirator fails, even if the regulator is properly sealed, the plant often finds that the gear oil in the regulator has been emulsed and the bearings have been rusted, eroded and damaged, as the regulator is in the process of being stopped and the gear oil is caused by water condensation resulting from the heat and cooling; of course, it is closely related to the bearing mass and the assembly process method is closely related. Solutions: selection of lubricants and additives. In accordance with the “f5” principle of lubrication work, the plant maintains thereducing machines so that each of thereducing machines is inspected on time by the person in charge. When the work reveals a marked increase in the temperature of oil, an increase in the temperature of more than 40c or 80°c, a deterioration in the quality of oil or a greater amount of copper powder found in the oil, and abnormal noise, the use of timely tests, troubleshooting and replacement of lubricating oils are immediately suspended. we'll use 220 # gear oil, heavy loads, high startup, poor useDouble-hole output reductionthe plant also uses some lubricant additives, and while thereducing machine is not functioning, the self-lock-reducing vehicle gear is still attached to the gear surface, forming a protective membrane to prevent heavy loads, low, high rectangular and contact between metal and metal at start-up. solutions: establish the corresponding lubrication maintenance track. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: There's three major problems with speed-reducing machines