Effects of lubricating diagonal gear reduction gear friction and wear

The effects of lumber-to-depressor gear friction and wear. The new turbos are in the early stages of operation because of the relatively high number of carving errors at the beginning and end of the condensation, larger impact loads, smoothings and friction coefficients, poor lubrication conditions and very easy adhesive wear. The supply of oil and the manner in which it is provided also have an impact on viscosy wear, with a sufficient supply of oil, which can improve the maximum load that binds and prevent the generation of wear, a better use of oil than the smoothing and cooling of oil baths, low temperature and strong resistance to viscosy wearServo motor reducerIt's better to spray side oil than side oil. In the case of fluid lubrication, the viscosity of the oil is an important characteristic affecting friction, so a change in the viscosity of the oil is effective in reducing the friction coefficient of the gears of the high gears. Extreme pressure additives vary in variety and in number of additions, and the effect on visceral wear is different. However, internal friction is increased in a moving friction because of the attraction of the metal surface with the adsorption layers formed by some polar compounds. From the point of view of the gear-reducing engine ' s gear friction, the good lubrication state of the gear rods is that of a less internal friction of their oil in the gliding area, while that of the stand-on gear-reducing machine ' s gear-relay point of entry is larger. However, excessive viscosity improves considerably on the internal friction of oil, which in turn affects the change in friction coefficients. (a) For mineral oils that are non-oil-free and very pressure-free, the higher the viscosity of the oil, the thicker the form of the film, the more adhesive, the easier it is to prevent direct contact on the side of the gear-reducing gear, and the greater the ability to resist the grinding; (b) For composite mineral oils with oily agents in mineral oils, it can also be used as a physical and chemical adsorption to form a more solid border oil membrane than pure mineral oils, and to shield vistas from wear and tear more clearly; For very pressurized wheel oils with a hyperpressurizer, it works with a standing gearGeared motorA chemical reaction of the gear surface metal, with a natural inorganic cage lid, results in the loss of opportunities arising from wear and tear。

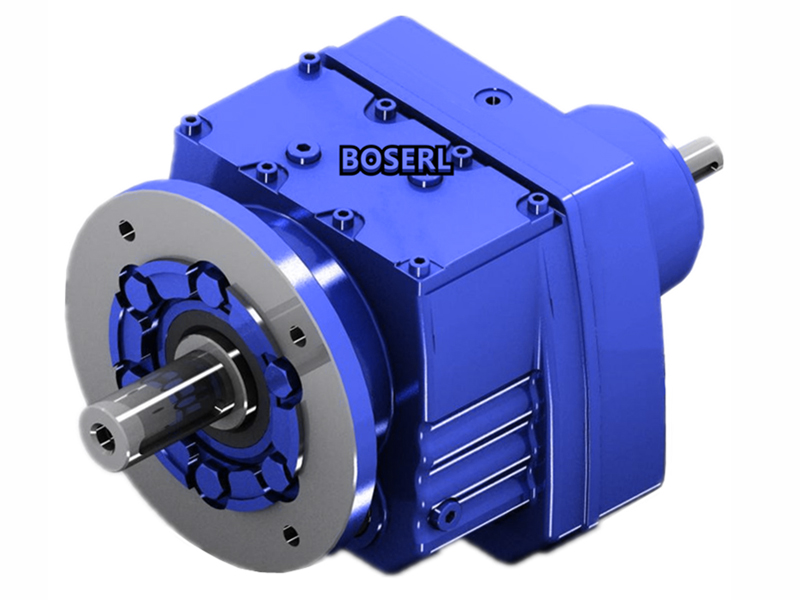

So to reduce itSpiral cone gear deceleratorRubbing of gears often uses lubricant oils consisting of extreme pressure additives, including active chlorine, sulphur, phosphorus compounds, instead of lubricant oils containing oil. Therefore, viscosity should not be allowed to progress indefinitely, but should first be appropriate. In the context of border lubrication, oily agents such as fatty acid are effective in reducing serene friction. While the flexi-fluorinated oil membrane thickness is significantly lower than that of the membrane thickness under the membrane lubrication premise, the viscosity of the oil increases the viscosity of the oil under high pressure, and the thiner flow membranes improve intensities, as well as the internal friction resistance of the oil itself, which not only affects the friction of the gear-reducing motor gear but also contributes to the high temperature generated by the smoother friction, so that the viscosity of the lubric oil is not too strong. Lubrication can affect the generation of wear and tear on the gear-reducing motor. The effect of lubrication on wear and tear: the wear and tear of the gear-reducing motor gear is closely related to the load and line of the gear and is directly related to factors such as material, the hardness of the tooth, the surface condition, etc. However, the effect of these factors on the gear-reducing engine gear varies with the condition of lubrication and lubrication, and in some cases the lubrication is the rightStand-by gear brakesthe effects of gear wear and tear have even reached a critical point. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Effects of gear friction and wear and tear on slow-down machines