Comparison of commonly used structures of the s-series axle-reducing-end motion seal

A comparison of commonly used structures for the axle end of s-reducing machines. sealed by oil rings:Stand-by gear brakesThe gear axes of the gears are moving, using centrifugal power to dump the fluids flowing out to the shell wall, and flow back to the oil tank along the wall of the snail snail snails, which is sealed in a power-type seal, which is appropriate to work on high- premises, with reduced sealing power under low- premises and loss of sealing capacity during parking. However, they require a high level of mass differentials in axle diameter, oil-covered troughs, roughness of the surface and hardness of the surface (thermal) of the axis. At present, snail snail snails have more specific sizes but most products are of poor quality and short life. combining sealing using sealing structures in two or more of the above-mentioned forms, but in snail snail nmrvRight-angle shaft reducer motorIn practice, most are not ideal. Another factor that cannot be avoided is the heating (heated with a furnace or baked with a torch) that is commonly used when certain heavy-mounted axes are assembled at a temperature of 200-300°C. or higher. This undoubtedly results in thermal transformation, melting and loss of sealing of the oiled lip when the coaxes are installed (because of small space). In practical application, however, it is not ideal to rely on this form of sealing ... so it can only be used as a secondary seal。

While snail snails are the usual money machines in mechanical equipment plants, the issue of leakage of lubricant at the axle end (activated seal) has not been brought to the attention of the manufacturer, but simply follows previous structural designs, which have caused considerable trouble to the manufacturer, and on this subject the author speaks of familiarity and practical experience. even with the use of an entrance skeletal seal, it has a useful life of about two years, often in the s seriesGeared motorPrior to the overhaul period, the oil seals were worn out of seals. And the mere replacement of the skeleton seals often cost more than several or ten times more than the oil seals themselves. When oil seals are installed, special tools are required to keep lips intact and process requirements are high. Bones oil seals: mainly through the use of spring rings, which are tightly sealed. So that they can produce the right trajectories to the axle of the snail snails, and when the lip is worn, which automatically compensates. To ensure that the mouth is properly sealed. Because of the short service life of this seal, it is rarely applied to the s series ofreducing axle. (b) pipe-trench trough sealing: sealing is performed using the curvature intertrenching effect. It is a non-contact seal with a long working life that does not require high maintenance. It can be used as a high- and low- condition for snail snail brakes. The skeletal seals are contact-type seals. They are simple, small and compact, and the seals are better. They are well adapted to the vibrations and axials of the s-series decelerators. It was originally due to the unfairness of these seal structures or to the poor quality of parts manufacturing, installation, etc. Besides.Helical-worm gearmotorfactors such as the viscosity of the lubricants, the oil and the ambient temperature of the equipment used affect the sealing effect and the useful life of the oil. the current structure analysis of the axle axle arcs of the snail brakes is sealed. the fur coil is fitted to a more compact size, easily disassembled, cheap ... but worn too quickly. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

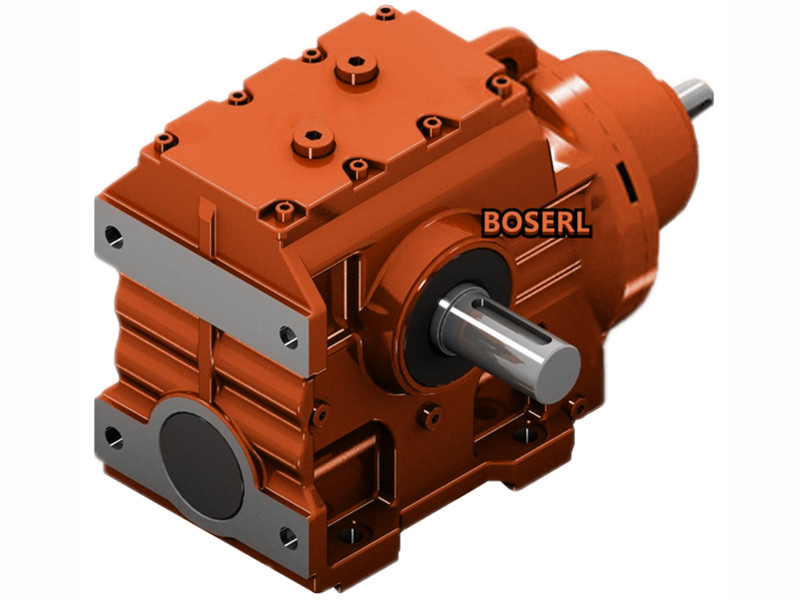

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Comparison of commonly used structures for axle-cutting sealing