A cortex-reducing and electrics set of gear number control tests

(b) A cortex-reducing and electric sets of gear-controlled numerically tested. I'd like to do a carving at the center of the five-axis processing of the paragus gear reduction machine to save accessGeared motorAs a result of the customization of the reprocessing process prior to the preparation of the nc programme, with a set of processing knife and machine-bed adjustment parameters, the programming of the nc for the ug-cam software automatically completed the preparation of the turbostats, the carving of the gear samples at the centre of the five-axis processing of the turbostats, and the performance of a set of cortex reduction machines and electric machines to verify the feasibility and accuracy of the work performed by the perforation-reducing machines and electric machines from the parameter design to the gear-processing process. How can the high-yield, efficient and high-quality optimization of the production of a tortilla-to-electric set of machines become the immediate setback? The complexity of the umbrella gears, which often require specialized machine beds and knives for the processing of such parts because of the complexity of their structure, brings with it expensive mechanical capital, combined with a large amount of programming time, which prevents small and medium-sized bulk producers from recovering their investments as quickly as large-scale production. to be designedMotor gearedThe process process process process is an essential step in determining the gears of the loaders, which are converted to a precise dent scale, a good co-ordinated competitor, a real gear with a physical moving function, and the traditional thermal process has been optimized, taking into account the characteristics of the size structure of the main gears themselves, which makes it difficult to ensure their quality。

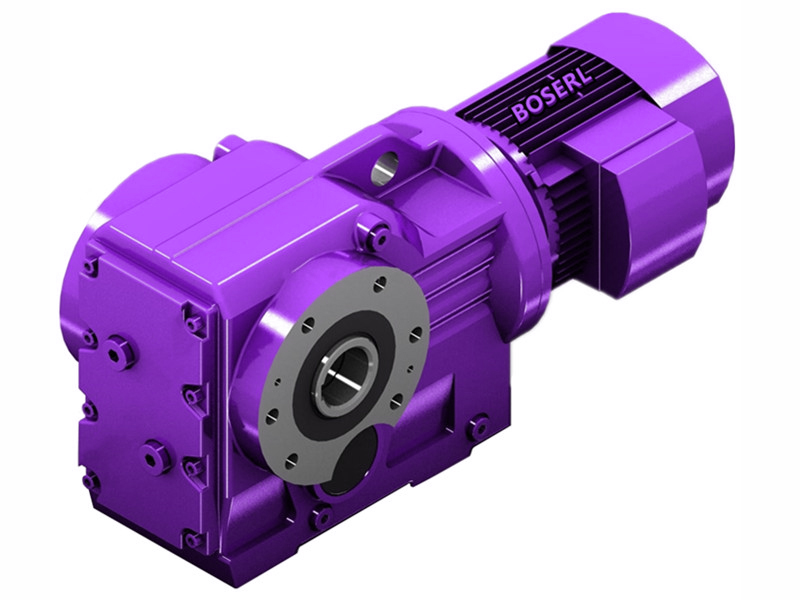

The outer diameter of the motorized gear from the turbo downer is 0.5 m because of its size and weight, which makes machine processing and thermal processing of deformations more difficult. In order to meet the needs of clients in terms of long-term durability and price and therefore to maintainAn umbrella gear-reducing machineIt's competitive. An umbrella gear processing process has been identified in front of the car seepage process using the ACLU? 2000 well-permeated carbon furnace (VBES-200/200), using the centre of the five-axis processing process in the carving of the paraplegic gear, thus saving, the calculation of the parameters of the paraplegic brakes and of the machine-bed adjustment parameters, and the production of a form-forming knife. Based on the experience of the gear process, the turbostats plus the electrics large and small gears use 20ANiCr42, which is highly resilient, to see the carbon steel. The high local weight of a set of active gear gears for the contours and electric power sets makes it difficult to avoid the deformation of the gears and the turnover of the gears following the seepage of the carbon acne fire, and it is often difficult to ensure the quality of the end gears following thermal treatment. The umbrella gear design for the turbo-charger is of great importance throughout the gear manufacturing process, as the complexity and uniqueness of the turbo-shaped structure of the turbo-patterns and electrics require a set of more equitable gear-deductors using the traditional design methods, which can be repeated over time, and multiple calibrations. Now, a three-dimensional image software for parasol gear is usually used to make a simple look, and then reformulates when certain design parameters of the gear change, which leads to an umbrella gear decelerator plus a highly repetitive process, and thus how to achieve itThrough-hole shaft reducerA simple, fast and efficient parameterization design with electric power has become an urgent task. Under development, the transfer wheel heat process has been optimized and the heat process has two phases, i.e. preparation of thermal process (the perforationreducing machine and the electric unit of gears for a high-temperature and a high-temperature back-to-fire car with a high-temperature back-to-fire second-to-hem) and post-cutting heat treatment (carbon-film and high-temperature back to the fire with a low-temperature response). Teething will now be pre-composed at the centre of the five-axis processing and subsequent processing procedures, as well as a numerical control process for gears prepared through the NC programming function of the UG-CAM software, and carving will be performed at the number control bed length. In view of the fact that the paratrooper of the paratrooper is not just passing power, it is also subject to shocks at start-up and brake. http://boserlgearreducer.com/product/list-kaxiiejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A gear-down and electric set of numerically controlled tests