Basic overview of s-series speed-reducing machines

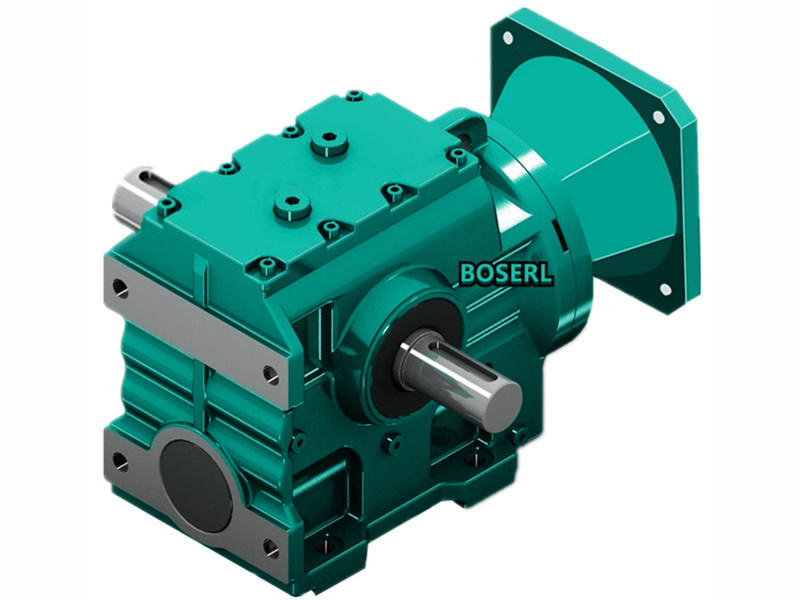

Basic overview of the s series of reduction machines. as a new type ofreducing machine for s series, the s seriesreducing wheel is introduced into the gear line, a curve that is equal to the logarithmicServo motor reducerThe same at the angles of the vortex on the line, the same characteristics of the rotor line and its equivalent curves, creates a new type of gear transfer - the gear transfer, so that it is equal at the vortex of the gear during the transfer, greatly improves the gear transfer and improves the transfer efficiency of the gear and makes it more stable during the transfer. The severe effects affect the motion accuracy. As the precision of machine work progresses and the rules of environmental protection law improve, it is also urgent that gear transfer be as smooth and correct as possible in order to reduce vibrations and noise and to extend the useful life of gear transfer components. At the same time, in order to reduce the noise of s-seriesreducing machines when they operate at high, a compact structure and a large drive ratio can be obtained that reduces the number of small gears in relative terms. Advances in gear loads have led to a growing use of gears during high- transmissions. While the material and thermal process methods of the s-reducing machines have been refined, the vibrations and noises of the gears during the s-reducing machines are still the more prominent topics in machine operations. In order to reducereducing motor loads and noises in the s series, the service life of progressive gears is reduced by the progressive processing precision, bringing the teeth closer to the required theoretical face, but progress in the processing accuracy is limited and very expensive; the alternative is to compensate for errors, such as processing errors and heat-processing deformations, which may result from the processing of these rodents and compensate for them when they are decayed. The s series ofreducing machines are important components in mechanical transmission devices and are efficient, structurally compact, reliable and of low use in manufacturing and maintenance. these two trends have brought the topics of gear vibration, noise and useful life to the fore and to the attention of gear theory researchers and researchersBig-rate slow-down machineThe producer's high-profile. the vortex of the s series of brakes is the opposite of the two gear sizes in the opposite direction, with a better degree of overlap than a straight cone gear。

The latter approach is often more economical. but because of errors in the gears of the s series, including process errors and heat-processing deformations, it is no longer possible to use the classic cortex justice theory to find a real line of contact and an area of contact, and the s seriesGeared motorSpeed-to- fluctuations; therefore, there is a need for reverse engineering to study the error between the real and the theoretical side of the s seriesreducing machines on the basis of a well-developed system for theoretic condensing of gears, based on process errors and heat-processing deformations. Tilt gearing is an important form of gearing, and the s seriesreducing machines perform a very important role. As science and technology continue to improve and society develops, the use of gears has become more widespread and user requirements for gears have become more stringent. The carving line of the ordinary cortex is the same curve, so it moves in a smooth way from the end to the other end, and enters the rodent in more than a straight cortex gear. There are a number of factors that affect the wheel in its actual conduct. Extensive applications have been made in various areas of engineering, such as mechanical processing, transport, aviation, chemical, metallurgical and mining. However, the traditional s-seriesreducing machines are moving in a way that brings with them a series of topics, such as severe tooth friction, inefficient power transmission and uneven movement, because the s-seriesreducing angles are not the same at different locations. on the one hand, the processing error of the s series ofreducing gears per se, as the influence of machine-bed processing parameters decreasedHelical-worm gearmotorThe accuracy of the gear processing, leading to the deviation of the theoretical and actual rodents from the cortex, gives rise to a cortex error, causing fluctuations in the ratio during the conveyance; the other is the installation and distortion of the gears, which, during the transmission of power and power, are primarily subject to rotation and twisting, which, after a long period of work, will result in a fixed deformation of the gearbox and the gear axis itself, so that the S series of gear-reducing gears will be subject to a fixed drive charge during the conveyance, which will cause a fixed shaking. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Basic overview of speed-reducing machines