Storage and lubrication of power-reducing and power sets

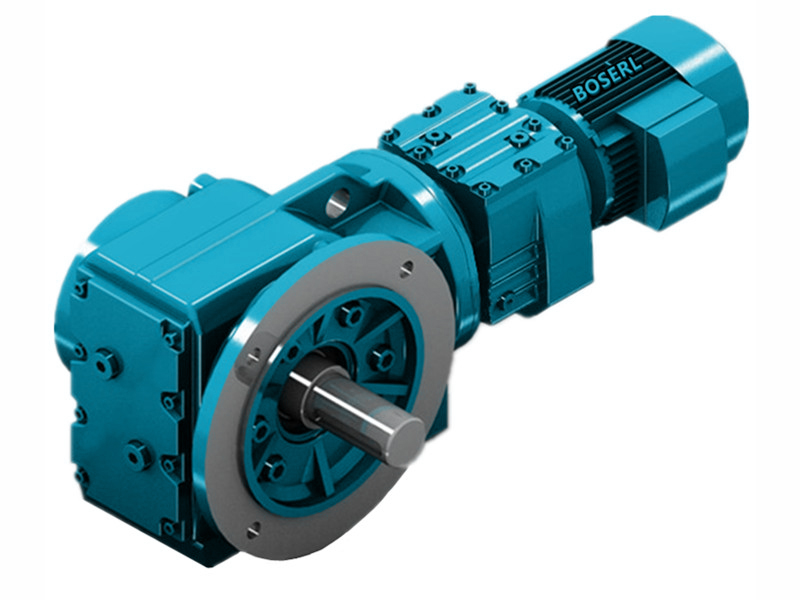

(b) Storage and lubrication of a set of power-reducing machines and electric generators. There is no need for any power balance treatment when power and its high power-reducing units are installed on an ordinary steel frame structure. For electrons with the same specification (central height), the total mass of the high power-reducing machines differs from the electric power set because of the effects of different output values, distribution of components and additional properties. IncludingStand-by gear brakesThe main circuits and ground enders of the charger, which also contain a wire end of the following components, including heat-sensitive electrical resisters, stationary heating elements, dual metal switches or PT100 electrical resistance elements. The above values shall be halved for each increase in the temperature of the bearings and double for each decrease in the ambient temperature of 15°C. The capacitors of the single-phase power plant will have the corresponding power force at the end of the main end of the power plant (even when the power plant is out of service). For secondary re-literation, only special ball bearings of lubricant may be used: lithium composite soap and minerals - or PAO oil lubricant; umbrella gear-added turbo-based oil viscosity of 100-150 cST (subject to 40C); density of NLGI2 or 3; temperature range -30C to +120°C (continuing). For normal parasol gearGeared motorFor the design of the powerer, the switchboard box is located in the machine and the cable import is located on both sides. It is necessary to check the co-operation of the turbo-barrel charger ' s corresponding bearings for high- operations. based on the premise that the electric power functions in a rated output state and the corresponding ambient temperature is +25°c (approximately 80c for bearings)。

A routing map of the turbo-charger auxiliary element can be found on the inner side of the end of the connector box. No more than thatAn umbrella gear-reducing machineHigh values of lubricant and bearing operating temperature of the press. Large power-reducing machines based on the same specifications and materials are expected to have a large weight set of power-reducing machines and generators. As a special option, some large power-reducing machines can rotate 4 x 90° for a part of the electrical set, and some machines have side-mounted wire boxes. All major lubricant producers can provide lubricant for the above characteristics. A minimum distance of 150 mm is required for an umbrella gear-retarder plus a circular guide. The loading and unloading of an umbrella gear-reducing machine and the powering unit must be careful to ensure that the auxiliary equipment and cables connected to the generator are not damaged. Unused cable imports must be blocked. If a high-power-reducing machine is equipped with an automatic secondary lubrication system, the amount of grease indicated in the above-mentioned chart would have to be doubled. These are described in the catalogue of products. In general, when the rate of rotation is multiplied, it is necessary to shorten the corresponding lubrication cycle, which is about 40 per cent of the figure in the above-mentioned chart. For the use of the power-reducing machine and the electric power set, the off-site of the electric machine shall be used to balance the power between the electric generator and the thinker unless the two machines are installed on the same steel frame base. For engines with specifications greater than IEC 280, a 0.75x70mm flat-guide or at least two 50mm2 round-guide lines shall be used. For high power reduction units and electric units, or for direct rounding units, the power reduction units can be connected to the corresponding voltage within the connector box in a high power reduction unit. The above-mentioned wiring does not have the corresponding electrical safety function; its purpose is to balance the corresponding power. For use at a higher rate of rotation (e.g., frequency transformers) or for low- heavy loads, it is necessary toPower-reducing machineset a shorter lubrication cycle with electric power. for a large power-reducing machine with a mass of more than 25 kg, the physical weight is marked on the corresponding placard. http://boserlgearreducer.com/product/list-kfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Storage and lubrication of a combination of speed-reducing and electric generators