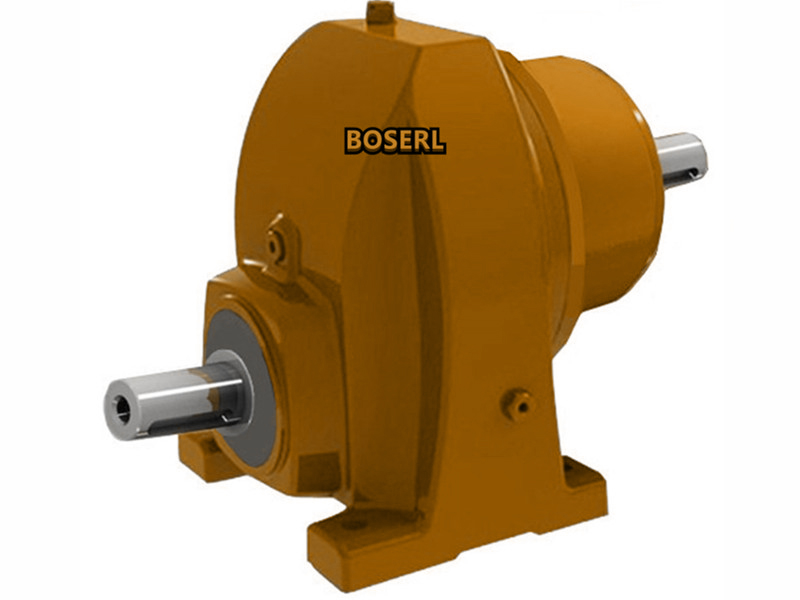

Part design for a coaxe-slash gear brake

(b) Design of parts for a co-axis slash gear brake. Modularization and serialization of co-axis slash gears have become a trend in the development of equipment products today. A co-axis slasher designer often encounters repeated general features when designing parts using Pro/E. The central theme of modular design techniques is the study of physical modelling, which is a new design approach based on the theory and methodology of humanization based on traditional design, conventional reliability and optimized design. In manufacturingVertical reducerThe development of a traditional “physical model mechanism for experimenting and design methods will undoubtedly cost a lot of money, extend design time and do not essentially capture the direct impact of structural design on the functioning of the system, so that the inefficiency and quality of empirical design will never escape. Modularization is achieved by simplifying the gear-reducing machine mapping process, reducing duplication of effort and improving design efficiency. Therefore, the gear-reducing electrician designer will take a considerable amount of time to perform this repetitive manipulation. Modularized design techniques, on the other hand, are a whole new development model that can innovate product development processes, reduce cycle costs, improve product design quality, improve progressDouble-hole output reductionDevelopment efficiency. The designer may use a high language similar to BASIC to prepare the Program of the model as required. Pro/E has a list of major design steps and parameters for each component or component model, namely Pro/Program. The integration of internal functions and the expansion of external functions, based on the maintenance of basic product modules, can be facilitated through modularization and serialization, which both maintain the inner wind of mature products and greatly broaden the space for product development. Motor geareds are an effective tool for automating parts and components。

This allows for the control of derivative parts by changing the values of the parameters. For example, screws, bolts, seatholes. In this way, the designer will be able to create its own user-defined feature bank, a rapid natural geometry model based on product characteristics, which will greatly improve the efficiency of the work of the gear-reducing machine designer. SymptomsGeared motorModularized design means the automatic completion of changes in the relevant sectors of the graphic by changing the size of a sector or sectors of the graphic, thus achieving rapid modification and design of the same structural mechanical products. User-defined features allow the same feature to be used on different parts, or for the integration of several system features of a coaxal slasher into a self-defined feature, using it as a general feature. It is a father's part by establishing the base parts, and then defines the shape and size of the control models for each control parameter in the family table. Pro/E will then be able to read the part or component through the operation of the program and obtain different geometric shapes through interactivity, so that the required family chart can be used to manage parts with the same or similar structures, especially for scale components. Including: general or non-extension of gear-reducing electrical features, size, general or no parts and componentsMotor gearednumber of parts and components, etc. following the rapid development of computer technology, modular design techniques for coaxial slash gears are increasingly being applied in a wide range of fields. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Part design for a speed-reducing machine