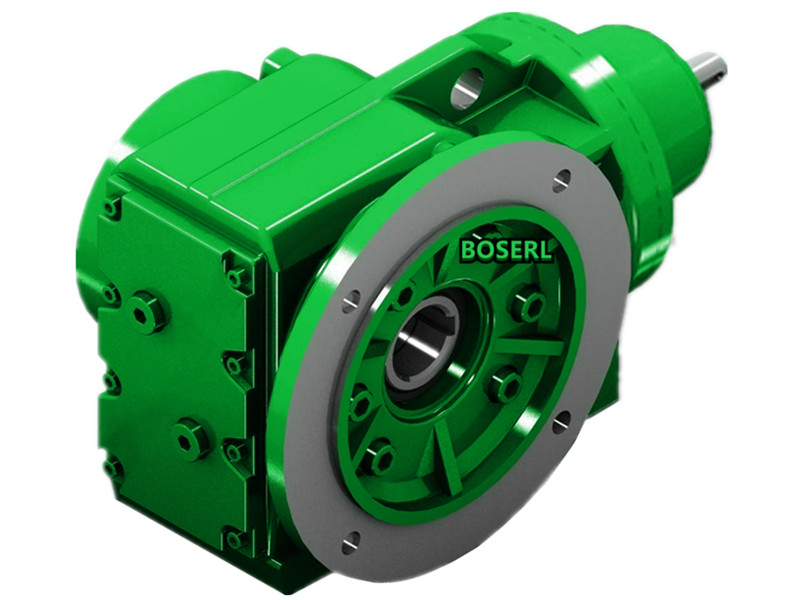

An umbrella gear-retarding machine

An umbrella gear-retarder piled up over the facility. In a centralized-driven suboptimal structure, brakes are usually installed on medium or low- axes and use large-powered rectangles and smaller-sized brakes. The disadvantage is that it's less scratchy than a chain, and it's increased by having to use a larger diameterSpiral cone gear deceleratorThe size and weight of the header. Therefore, it is applied across the working community and is an extensive scratching component applied on cranes. For large-scale equipment, such as a stacker, the self-weighted balance of the arm frame is mostly mobile. However, this disadvantage does not normally affect the application of wire ropes on cranes. Coal-system stackers overlay institutional brakes using vortex brakes, electromagnetic brakes and electric pushers. The range of an umbrella gear-reducing arm is changed by the use of steel-wire ropes through a slider group to the perpendicular roller, relying on a perpendicular roller to put a wire-relaying line on. As can be seen from the overlooking body-driven approach, the perusal consists mainly of electrics, brakes, umbrella gear-reducing machines, rollers, sliders and steel wires. The reverse of the roller is achieved by changing the switch of the electric power, and the angle of the arms overlay is achieved by brakes. The principle of mobile weight balance is to use leverage systems or zips to move the arm racks along a line of similar horizontality with the weighted synthetic gravity, i.e. to apply the increase or decrease in the weight of the balance to compensate for the decrease or rise of the weight of the arm. Some uplifting institutions (e.g. hand-stamping) use a different scratching chain to promote goods. Umbrella gearGeared motorThe brakes are placed on high- axes and require a small power rectangular that allows the brakes to be light in weight and small in size。

It's an indispensable part of the umbrella gear-reducing wheel-crasherGear motorsIt is an institution of fundamental importance, and the quality of its performance will have a direct impact on the technical functioning of the collectors. The strength of wire ropes, compared to chains, is that they have a high carrying capacity to withstand larger shocks; are lighter; work is reliable; the external wire is fractured and loosed prior to break-up, and therefore easily found and replaced in a timely manner; the money is low; and work is smooth and non-morbid at high rolling. The arm-stands are primarily used to regulate the height of the arm-frames at the time of the extraction of the stacks and to meet the production requirements of other agencies. The motor rotates through an umbrella gear-retarding machine, which causes the wire to go around or out of the cylinder, thereby altering the size of the arm frame. The wire ropes are used not only for lifting cargo in cranes and for operating grabs, but also for the operation of towing cars and the rotation of the rotary sector driving cranes. A second brake can be installed on the other end of the high- axle of the brake, or an umbrella gear-reducing mechanism motor may be installed on the end of the tail axle of the electric engine, subject to the selection of the two-axis axle axle. An umbrella gear-reducing motor is usually used as a closed brake, which is linked to an electrical circuit。Right-angle shaft reducer motorform and profile of the sub-optimal agency drive: the sub-optimal body is placed on the upper part of the rotor, and the sub-optimal structure consists of the drive, the conveyor, the brake, the twisting system and the security aids. when the power rectangular is larger, two brakes are sometimes installed on high- axes. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-deficit arms racks overlooking the facility