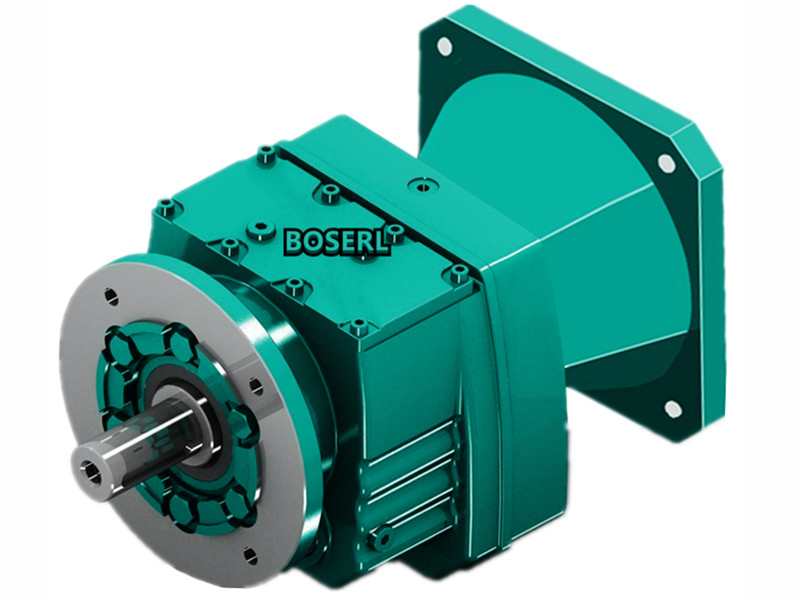

Equipping and disassembling of a standing gear-reducing power plant

(c) The assembly and dismantling of a standing gear-reducing power plant. 16000-26000 load hours (for 2 polar and 2/4 polar machines (1)). In order to avoid a vibration in a standing gear-retarder, a half-key balancing of the coaxial sector or belt wheel is required after the key slot has been processed. During the operation of a standing gear-reducing power plant, the series ofreducing machines can be re-oriented. Special care must be taken for the bearings. In the event of an anomaly in a standing gear-reducing power plant, the machine must be removed and the relevant parts checked and, if necessary, replaced. 32000-45,000 load hours (for 4 polar machines (1)). For the automated lubrication system, the grease is requiredMotor gearedThe export pulverization is permanently unloaded. The assembly accuracy of the fixed gear-reducing axle-column sector is as follows: check if the b gap is less than 0.05 mm and the a1 to a2 gap is less than 0.05 mm, at which point only half-utilized lubricant can be injected, and then the power is operated at full and lasting for a few minutes. Machines with permanent lubricating bearings are usually with Z or 2Z permanent lubricating bearings for machines with a specification of 180, and the type of bearings are assigned to the respective product catalogue or to the placards of each of the machines for a fixed gear reduction machines with a specification of 112 or more。

In order to avoid a vibration in a standing gear-retarder, after the fixed gear-retarder cell has been processed, the coaxial sector or the belt wheel must be balanced in a full-key state. If the machine has a lubricant hint, the assigned parameter values must be followed. Attention must be paid to all rollers! Re-(second) lubricating steps are as follows: unloading oil when it has an export plug; pressing new lubricant resin into the bearing until the daily grease is pumped out; and allowing the electric power to operate for one to two hours to ensure that too much oil is squeezed out of the bearing and, if there are any, the export plug is tightened. It is prohibited to install or dismantle axle-secticular units and belt wheels, i.e., by means of a flat gear-reducing electric press or by squeezing the case with a pole. Installation of standing gearsGeared motorThe joint axle sector and the belt wheel must be equipped with appropriate equipment and tools to install the joint axy sector and the belt wheel, and ensure that standing gears do not cause damage to the axis. Depending on the use and load status of the standing gear-reducing power, reference can be made to the respective product catalogue. The performance of the bearings is checked in the following ways, including listening to the sound, vibrations, bearing temperature, inspection of waste grease or monitoring of spm bearings. After 1 to 2 hours of operation, shea-export plugs, if any, are tightened. In general, a half-key approach is required to balance the processing and red tape on the axis, with the sign " half-key balance processing ". for stand-by generators, the operating hour is half of the above。

We're gonna have to check the gear-reducing machine on scheduleHangerreducing powerBe in a state of cleanliness and ensure good wind flow. If a full-key approach to balancing is used, a yellow tape must be placed on the axis, with an indication of " full-key balance processing ". If not possible, lubrication can be performed when the machine is shut down. Check the axle seals (example ivv seal rings) and replace them if necessary. When a standing gear-reducing generator stops, the remaining lubricant can be pushed into and replaced. Check the interface, assembly and bolt. Standing gear-reducing machines are required to be dismantled using tractors and to be heated or assembled using special tools. Subject to an ambient temperature of 25c, l1 can provide a good lubrication effect (direction only) in the following operating cycles. A smaller number of times is used for a larger-specified, fixed gear-retarder. If a non-key method of balancing is used, a blue tape must be placed on the axle, and the assembly and dismantling of the marking gear-reducing power plant with the indication of “non-key balance processing” can only be done by qualified staff using appropriate tools and manipulation methods. The rotors of a standing gear-reducing power plant need to improve the traverse balance. howVertical reducerthe axes are elaborated in a separate protocol later. http://boserlgearreducer.com/product/list-rfxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Installation and disassembly of speed-reducing machines