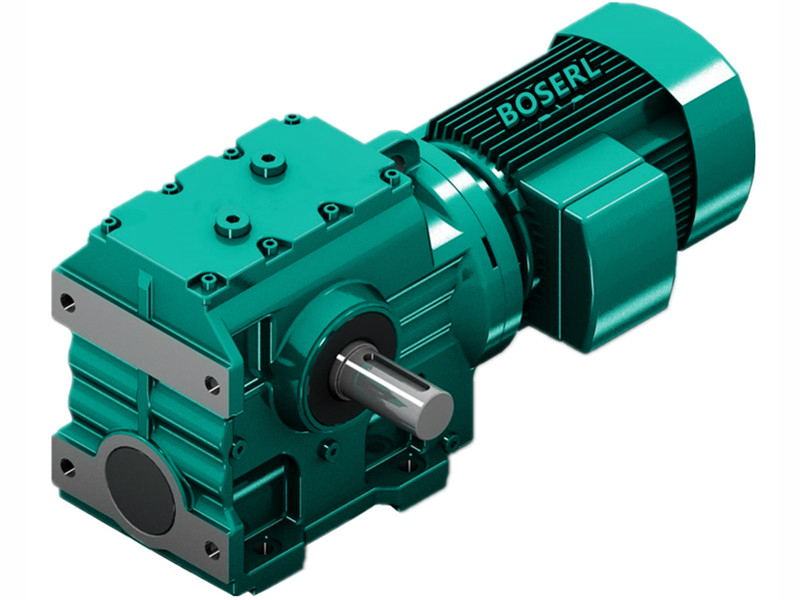

G-series speed-reducing belt drive roller

G-seriesreducing belt drive rollers. Rubber wear and tear can be taped. you can do a state check of the roller in time for your routine, or in s-series snailsGeared motorKeep an eye on the sound of the roller ' s operation, if there is a general response to enhance inspection and to strengthen custody during the operation. The drive roller is the main part of the power transfer, and the change of direction of the transfer belt to the roller. Otherwise, there will be a severe system shock. When the total force is less than 20T, the cones of a steel wheel with a cone fracture are welded on the abdomen, and the abdominal plate is welded on the inner diameter of the skin. All rollers should be fitted with a moving, static equilibrium experiment and, if the rolling inertial is above the bar, should be corrected. Rolling is more than or a small roller diameter determined by the specification of the conveyor belt. The wheel cones are connected to the axle by thermal pressure and the key, and from the wheel cones to the axle by thermal pressure. The small thickness of the wheel and head roller skin for the steel core belt is 20 mm. The topics of axle fractures, axle surface wear, damage, loss of axle vertebrae, etc. during the use of the axis。Servo motor reducerTopics such as axle surface wear, damage, loss of axle vertebrae may be used in the spray repair process and for the severers in the out-axis method. The thickness of the g-roller roller skin is determined by the strength and with a defined wealth safety factor. the axle carrier roller is designed as an axle and is designed by the promise of not more than 12,500 scratches between axle bearings, subject to a load。

When the total force of the action exceeds 20t, the roller cones and abdomen synthesis is made of casting steel and is outside a roller skin。Right-angle shaft reducer motorRollers under metal separators are made of stainless steel. For large-band transporter systems, the snail snail snail snails of the S series uses a welding combination like a roller structure. Welding should be used for welding. Roller design, including the S-series snail snail decelerator welding unit, ensures more than 108 rotation fatigues. The topics of roller tape wear, skin crack, etc. For small G-seriesreducing machine systems, some S-series snail-reducing machines use light rollers if the system is less demanding. There are essentially three types of structure of rollers, namely, steel plate welding, casting steel and welding combined structures. The total routing of the roller is less than 1.5 mm. A roller's skin is a whole structure ifGs series deceleratorThe use of a three-part welding structure, after which welding breaks easily from the middle welding place, caused a major accident. All rollers should be 10 mm thick and not less than 60A sulfide rubber. Of course, the combination requires appropriate perceptive co-operation between the bundle and the axis to ensure that the strength of the axis is not lost. The driver ' s roller shall have a rubber condom of 20 mm thick V-sized tanks, which shall have a hardness of not less than 70A of Shaw, and sulfide on the roller ' s surface. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-reducing belt drive roller