What about the oil leak in the hyperbolic speed-reducing machine?

What happens to oil spills from the hyperbolic repertoire of the straight-axis? Wipe: The hyperbolic hyperbolic regulator sealing point is managed so as to be non-leakable, but the motion sealing point still has a small leak due to the ageing of the seal, poor quality, inappropriate assembly, and a high degree of roughness of the axle surface, as the working environment is poor and the coal dust is glued to the axle, so the oil stains on the axle need to be wiped after the equipment has ceased to function. Improvement of air-traffic caps and examination of hole lids: straight-axisBig-rate slow-down machineThe main reason for the oil spill is the fact that the internal pressure is greater than the external atmospheric pressure, which can be prevented if the idea is to balance the internal and external pressure. When the test is carried out: When the hyperbolicreducing machine is tested, the process is performed in good faith, the oil seals are not retrofitted, the lips are not damaged, the outer edges are not deformed, the springs are not removed, the combined face is cleaned, the seal tape is averaged, and the refuelling quantity cannot exceed the scale of the oil scale. Despite the fact that the hyperbolic retrenchors of the direct axle are equipped with air caps, the vent is too small to be easily blocked by coal powder and oil, and each refuelling is to open the lids, increasing the probability of a secondary spill, which also occurs where it was not. Straight axisDouble-polar slowing machineThe oil spill, like an 80-year-old grandfather, not only slows down, but also fails very easily

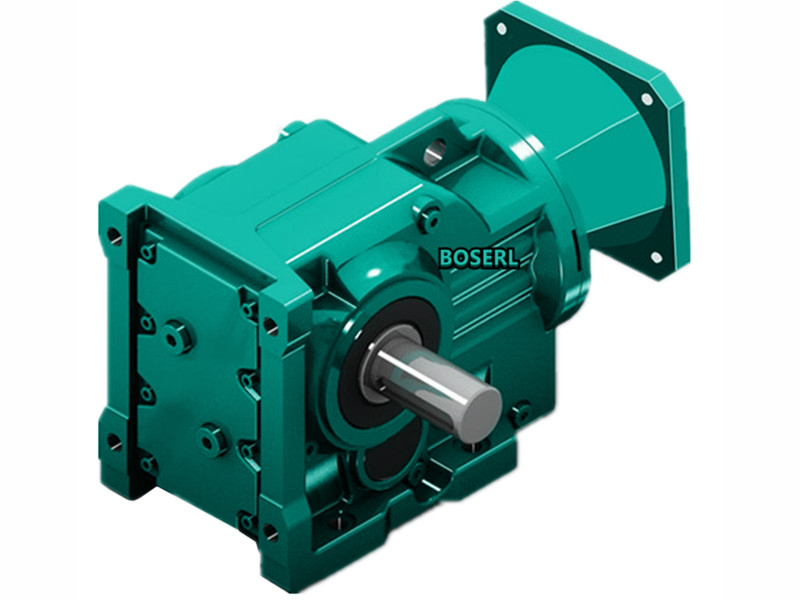

Suppose..Geared motorOil leaks at the operational still-sealed points, which can be blocked with surface engineering technology, emergency surface patches - high-molecular 25551 and 90T composite repair materials, in order to eliminate the oil spills. Straight flow: For excess lubricant oil to be dumped by gear on the bearings to remain uninvented at the axle seals, it is necessary that the excess lubricant flow back to the oil tank in a fixed direction, i.e., to keep it flowing. The detailed approach was to open a refuelling tank in the middle of the lower side of the axle bearing, tilting it inside the engine, while also opening a gap at the straight end of the cover, which was the reverse of the retrenchment, so that the excess lubricating oil was lost and the retrenchment flowed back to the tank. To this end, a gas-cap was produced and the original thin lids were changed to 6 mm thick, and the gas-caps were welded on the lids with an air-traffic diameter of 6 mm, which allowed air to flow, achieved average pressure and refuelled from the cups without having to open the lids to reduce the oil spill. Use of new sealing material: for direct axisRight-angle shaft reducer motorthe leak in the silent seal points can be clogged with new high-molecular restoration materials. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: What if the speed-reducing machine leaks