Safely past the axle gear brake

Safely through the grinding period of the axle gears. Before manipulating the axle-slash gear brakes, it is necessary to read the maintenance imitations, manipulate them in accordance with the requirements of the imitations and keep information for a long period of time to facilitate maintenance. Characteristics of the time of grinding of the coaxe slasher: high rate of wear because of newZip-tooth decelerationThe effects of such factors as the processing, assembly and commissioning of spare parts are smaller than the co-exposure, and the associated twirl is larger. It is often observed that general anomalies should be removed from parking in a timely manner and that work should be suspended until the cause has been found and the failure has not been eliminated. Equivalent lubricating oils, in particular gear-reducing motors with a power greater than 11 kw, must be filled with load-loading wheel oils, paying attention to the frequent inspection of lubricating oils, hydraulic fluids, cooling fluids, oil levels and quality, and to the sealing of the whole machine. Manipulation failures are due to a lack of understanding of the structure, functioning of the coaxial slasher and, in particular, new manipulators, who easily cause malfunctions and even mechanical and safety accidents as a result of their failure. The lack of oil was found to be excessive, and the reasons should be analysed. Lubrication: as a result of the relatively small gap in coxlear gear reduction machine parts newly assembled, and because of, inter alia, assembly, lubricating oil resins are not easily able to form an average oil membrane on the friction surface to prevent wear, thus reducing lubrication efficiency, causing early abnormal wear in the gear-reducing power plant, causing a well-coated scratching or bite, and causing malfunctions. the gear-retarding power plant is operating with each other's condensed parts on the surface of the parts, and the scraps of the metal that have been worn off, which are also used as grinding material to inherit intervention in friction, which acceleratesAn umbrella gear-reducing machineThe parts are accompanied by wear and tear on the surface. When the wear and tear is too high, overloading can result in damage to spare parts and early gear-reducing electrical failure. Therefore, the triage period occasionally increases leakage. At the end of the grinding period, the machine should be subjected to compulsory maintenance, which can be summarized as: enhanced training, load reduction, vigilance, enhanced lubrication。

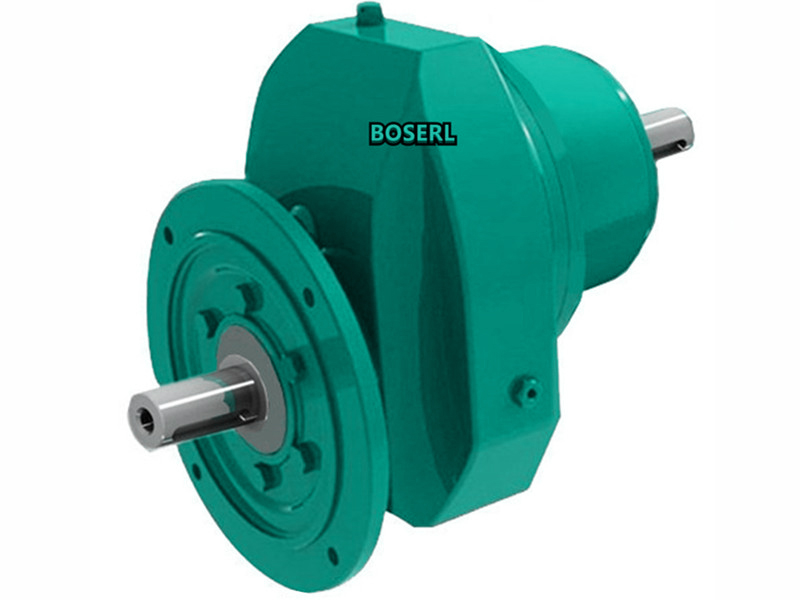

As long as maintenance and maintenance of gear-reducing machines is addressed and implemented as required, early failure will be reduced, service life will be extended, productivity will be improved and coaxial tilt gears will be reducedGeared motorBring you more. A maintenance copy of the product supplied by the manufacturer is required for the operator to manipulate the equipment. Leakage occurs: because of the loosening, vibration and heat effects of the motor parts of the gears, the sealing surfaces of the gears and the mains of the pipes can spread defects such as leakage, sectoral exercise and so forth, which are difficult to detect when fitted for debugging, but which are exposed as a result of the vibrations and shocks during the course of the work, as reflected in the leakage (e.g. seepage). The retrenchor with the stand-on pump is careful to rotate the pump and the clockwise is accurate. Facilitation occurs: newly processed parts and components, with geometric and cosmometric deviations, easily relaxing the previously solid components at the beginning of their use due to exposure to the intersectional loads of shocks, vibrations, etc., as well as to heat, deformation, etc., and excessive wear and tear. Maintain coxle-slash gear brakes to be clean, adjusted in a timely manner, and secure loose spare parts in order to prevent their wear and tear, or loss, as a result of relaxation. Pay attention to the grinding of work loads during which work loads do not exceed 85 per cent of the rated workload and are carried out to prevent the occurrence of overheating caused by long hours of continuous work by the axle gear reduction machines. Use and maintenance of a co-axis oscillating gear reduction machine:Motor gearedoperators should be trained, mentored by the manufacturer, have a full understanding of the structure, functioning of the gear-reducing power plant and have established experience of manipulation and maintenance. as a result, parts and components are easily caused during the grinding period, in particular the wear and tear of the co-operative surface. at the same time, the lubrication of various lubrication points should be enhanced, and it is recommended that lubrication of the lubrication points be introduced on a weekly basis (except for special requirements) during the milling period. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: The speed-retardation period