Aggregation analysis of the gear-reducing vehicle

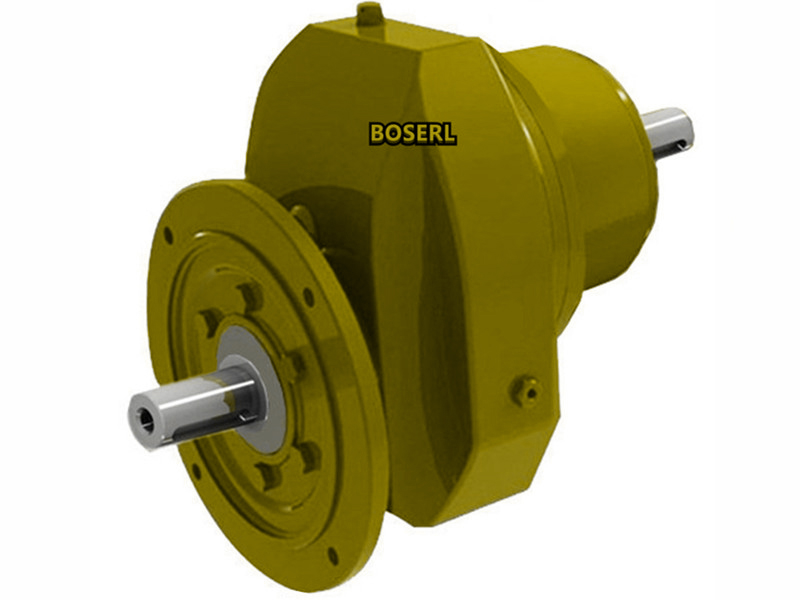

Diagnosis of the gear-reducing gear axis of the recoiler. However, the gear axes in the rectangular gears are fractured during their use, and the chemical composition of the gear axes is overhauled by technicians, and the carbon, chromium, molybdenum content in the steel meets the material content requirements. (a) The gold phase of the 2nd test cortex fracture, close to the surface of the cortex, which can be seen in a luminous luminous and iron body, with a typical resilient bouquet, with significant plastic deformation; The gold-shaped tissue of the gear axis shows that the white mass is iron, the grey is bead light, the axis is bead light and iron, and the rectangular gearGeared motorThe gold-phased tissue on the surface of the medium gear axis is also luminous with iron, proportionate to the state of repulsion. The dim colour of the fractured face is a fibrous zone, with a significant radiant radial cavity, and a relatively smooth surface with a cut lip, which makes it possible to determine that the cut is a plastic cut. No cracks were found in any of the parts of the shipment which were injured by magnetic powder. This is due to the unfair process of the thermal processing of gear axes, which results in the corrosive axle axle and the cortex surface tissue being the same as the pelvis luminous luminium luminium and iron. If the turbation is performed on the turbary axle, the tissue should be the backlash, as shown by the contrast between the turbular tissue and the mechanics of the spherical tissue, which shows, in the case of the same degree of hardness, that the carbon seepage is in a spheric shape with a high degree of yield, plasticity and resilience, i.e., the repulsive tissue has a high combracing power, as shown by the macro-branch fracture of the contangular fracture of the contangular axe, which is vertically at the cortex of the cortex line, and where there is a significant transformational deformed area near the surface of the cortex, which can be judged by the fact that this is the caseRight-angle shaft reducer motorThe middle gear axis is fractured by cutting。

Fracture analysis of gear axes: Modified to cut at approximately 1.5 cm from the fractured side of the gear axis, the wheel was considered to be the fractured side of the gear. The gear-reducing engine ' s gear axis was a radial axis, with fractured cross-sections mutation in structure, easily creating a concentration of stress and fracture. Fracture analysis: The chemical composition of the gear axis and the magnetic powder detection injuries meet the requirements, while the hardness of the gear reduction engine gear axis does not meet the technical requirements. The plastic cut-off often shows fibrous, radioactive and lip cutting areas. The gears are..Motor gearedImportant parts, some of which are gear-retarding motor gear axis materials, are selected for 42 CrMo steel. In accordance with the design requirements, gear axes require modulation so that cracks cannot be promised when the hardness reaches 210-280HBS. Gold Organization Analysis: In order to facilitate the Golden Organization Analysis, small sections are intercepted on the disk shown in the chart and two samples are separated for the preparation and observation of the Golden Organization. This will require the selection of a fair-minded thermal process, which was later determined to be 850OCX3.3h, 30-50OC tankers returning to the oil plume; 650OCX6.6h, water cool or oil cool. The test position for test No. 2 was close to the cog axis surface approximately 2 mm and the fractured side of the cog axis was close to the cog axis surface; the test position for test No. 3 was close to the cog axis for the preparation, organization observation and photographing of the gold-synthesis side of test No. 2 and 3. The following is an analysis of the break-up of the gear-reducing motor gear axis and the development of equitable thermal process parameters. Thermal process of this material is so difficult to control that its mechanics are difficult to meet. In originalZip gear brakesThe hardness test of the medium gear axis, which is approximately 1 cm thick at the end close to the fractured side, was used to test the sample for the hardness, the location and results of which showed that the hardness from the gear-reducing engine axis to the axis surface was 6.0, 12.7, 13.5 and 10.8 HRC in descending order, while the technical requirement for the gear-axis was 21-28 HRC, and the results showed that the hardness of the gear-axis in the gear-reducing vehicle did not meet the technical requirements. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: We're going to need a breakup on the gears