Analysis of lubrication in a gear-reducing machine from a frictional point of view

An analysis of lubrication in a standing gear-reducing machine from the point of view of friction. The lubrication of gears in a standing gear-reducing machine is compared to the lubricating of mechanical parts in the gears: the gears are compared to the slide bearings, because the curvature radius is very small and the contact time at each location is very short when the rods are condensed, so the preconditions for the formation of oil weeds are poor. GearGeared motorThe larvae starts with a relative slippage, and the direction and size of the velocities continue to change dramatically, and the slide direction of the root is the opposite of the direction of the moving bullet, with the prerequisites for the formation of the oil membrane being far removed from the bearings. The lubrication status of gears is closely related to the stress of contact with the tooth, the smoothing and direction, and the function of lubricants. The linear velocity of the gear has a significant impact on the ability to form a fluid lubricant film, with a line surface of the gear, a small area of exposure at a condensation, a high rate of transmission power, a very high exposure pressure and a constant change in the value of the force of the dent exposure, and therefore requires a high carrying capacity of the lubricant film. As a result, the re-establishment of the oil membranes is required for each coupling. In gear-retarding machines, when the friction subsurface is directly exposed and relative motion occurs, friction and wear will occur, resulting in increased energy consumption andGear-retarding machineThe life expectancy is reduced. When gears in gear-reducing machines operate at fixed loads ands, lubricants will be engaged in the form of fluid-powered oil wedges, which will absorb the loads, thus completely separating the condensed carving surface and turning the dentures into frictions between the subsectors of the oil membrane, which is called fluid-activated lubrication。

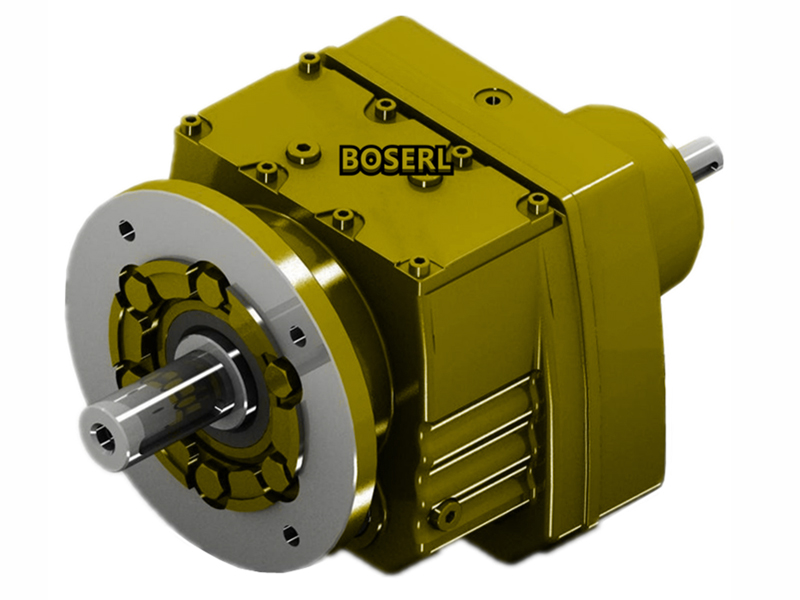

The lubrication of a standing gear brake, which includes, inter alia, the lubrication of gears and bearings. On the basis of these special characteristics, fluid or elastic fluid-pressure lubrication between the condensed gears is subject to certain limitations. This paper begins with an analysis of the lubrication of gears in the gear-reducing power plant from the point of view of friction, in order to draw attention to them。Motor gearedBecause of its tight structure, its efficiency, the soundness of its transmission campaigns, and the simplicity of its use. It is widely used in a variety of engineering machinery to reduce or increase the of work structures. Gear contact surfaces cause processing difficulties due to the special nature of their gear curves, which make it difficult to obtain higher processing accuracy and the surface is less luminous than the spare parts, which increases the resistance of gear-sliding frictions and makes the gear-reducing machine uncontinuous. While the working function and useful life of a standing gear-reducing machine is related to many factors, such as the geometric parameter design, material, processing, thermal treatment, assembly and use of parts in the gear-reducing machine, the lubricants of the gear-reducing machine are often important and interesting topics, the purpose of which is not only to create a suitable thickness of oil film to prevent or mitigate the harm caused by direct contact between the friction subsurfaces, but also to improve efficiency, increase heat dispersion, prevent rust, mitigate impact, reduce noise and vibration during work, and remove worn metal powderStand-by gear brakesnormal use, so lubrication is, in a sense, a good, bad hub for the design, construction and use of a standing gear-reducing machine. if one considers the effect of high pressure on lubricant viscosity, and local deformations that occur after exposure to surface loads, this constitutes flexi-fluorinated pressure lubrication, which is desirable. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Lubrication in speed-reducing machines