Standards of use and precautions for 380v speed reduction machines

Standards and precautions for the use of 380vreducing machines. Technical knowledge requirements: machine functionality and the use of know-how and lubricant used in machines, as well as knowledge of associated hazards, are suitable for detailed manipulation and environmental work. yesGearbocBefore any manual manoeuvres or the start-up of automatic rotations, ensure that there are no barriers and staff in the area of work. Three-hundred and three hundred and thirty-eight-v power-reducing machine maintenance staff often touch the cleaning and lubrication of machine parts (buttons, tampon, etc. ) and perform simple maintenance work (loaning). According to the security classification, working staff are required to wear labour clothes and labour-insurance items (shoes, helmets, glasses, etc. ). Measures required to maintain operational quality. The designer can be contacted if there is some confusion about the description of the sequence in the three-way 380v reduction machine manual. The three-stage 380-vreducing machine is often verified to meet the pre-defined requirements (working-cycle one sets off a working component). During inspection and maintenance, it should be ensured that the equipment is not activated. All movements are often checked manually before the 380vreducing machine activates the automated system. When work is completed on the 380vreducing machine, the moving parts or parts of the fixed position of the 380vreducing machine to be used in order to avoid collisions. i've been checking 380vsGeared motorReliability of the bearings and the rest of the sector structure. When a failure signal is detected by a staff member (suspect of fault, inaccurate movement, abnormal sound), an accurate hazard mark should be made on the equipment. In each case, the following delimitation shall be guaranteed. Cooperation with staff responsible for regular and extraordinary maintenance。

The “suspension button” is often checked for good (see the electrical technology imitation list) to operate only when security initiatives are normal. Prior to the start-up and manipulation of the equipment, it should be determined that all the protection devices and protection initiatives for the 380-phase 380vreducing machine are fully in place and fixed. often overhauling the operation of electrical equipmentDouble- power deceleratorWhether the wire connection is accurate and whether there is a dangerous or non-disturbed interface to manually check the operation of all electrical units. Check for more specific instructions and warnings, machine end marks, accident-prevention signals need to be clearly visible. Appropriate lifting and assembly equipment should be used. In case of an accident, the red stop button should be fully pressed and the main switch for the equipment should be blocked (see the electrical technology simulation). If you are not fully aware of the manipulation process, do not engage in any manipulation. Scale work of the 380vreducing machine staff: restructuring of mechanical cracks in the motor chain, inspection of safety device implementation and mechanical adjustments, examination of mechanical cracks and wear and tear of parts (shelter, small gear, etc. ) and repair of machinery before replacement of spare parts with original spare parts. In manual manipulation, quick switching should be avoided between different actions. During inspection and maintenance, three-phase 380-vreducing machines should be stopped. Equipment is often maintained (cleaning, lubricating) to ensure that key sectors (switches, buttons,reducing devices, etc. ) remain normal. In the case of manipulation within the working area, work should be carried out with sufficient light and high visibility. All mechanical parts function properly to ensure that those sliding and moving parts do not pose a danger. Accurate use of a 380v power-reducing machine will ensure the functionality of the equipment and enable it to operate safely. under normal operating preconditions (automated mode)Three-hundred-thirty-eight-fiveUse and post-emergency manipulation recovery. The department or body of the 380Vreducing machine is often inspected in accordance with the manual of use, including instructions on the use of the installation. http://boserlgearreducer.com/product/list-fafxilijiansuji-cn.html

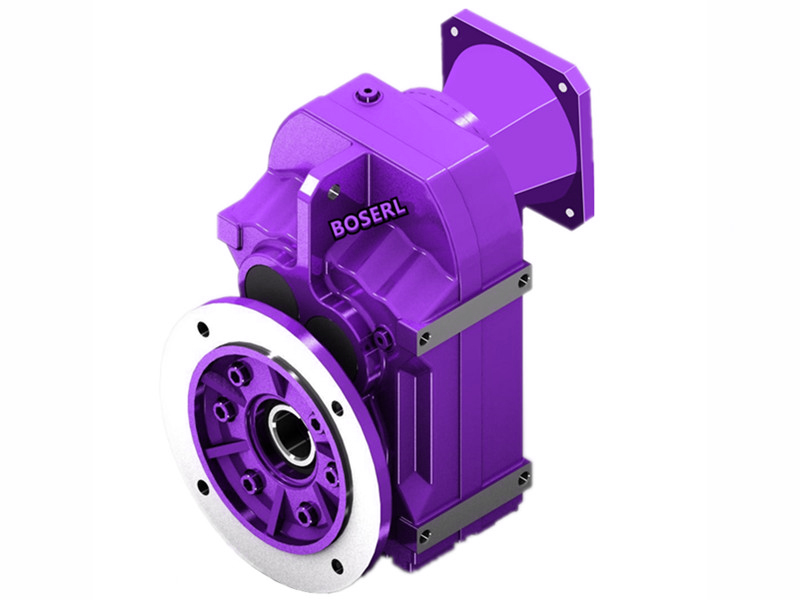

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Standards for the use of speed-reducing machines and preventive measures