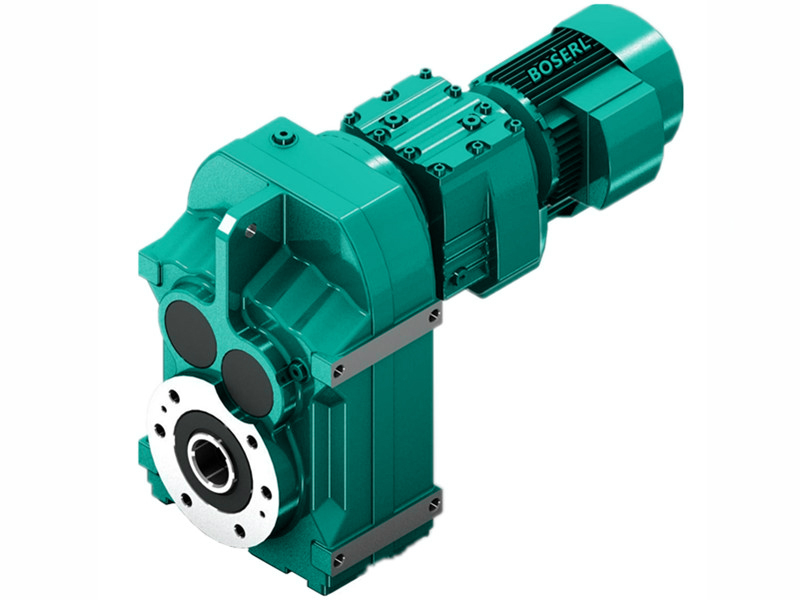

Input maintenance and maintenance of parallel axle speed reduction and electrical sets

Input maintenance and maintenance of parallel axle reduction machines and electric generators. Attached to the drawings you can find the location of the aqueous and fluid indicator. In addition, prior to the initial start-up, the same oil was added to the pipeline through the oil-entry pipeline to improve the pump-suction capacity. The parallel axle-reducing and electric-released pipes have been blocked for transport at both ends. It is then necessary to refuel at the bottom of the gears. Following the initial start of the pump, the pipeline shall be filled with oil. Prior to initial start-up, it is necessary to ensure that the pumps are oiled to avoid damage to the pumps. It's very interestingVertical reducerThe pumps may not breathe any air, otherwise they may be damaged. After a period of time, when all the pipes have been inflated, the oil must be re-inflated to the upper mark of the meter after the time when the fuel pump of the f series was shut down. In the assembly process, dust protection is to be observed in order to prevent the entry of foreign miscellaneous and dust into the gears during the initial operation. all pipes should be completely clean (using compressed air) before the pipelines of the f series slower are assembled。

LaunchGearbocWelding and preservation of oil pipelines, both inside and in the upper end of the gear set, with external paints and internal preservations have been performed. Depending on the level of contamination, it is now necessary to clean or replace all filter components for the restart of promised gears. If necessary, gear institutional oil must be refilled with the upper mark of the fluid indicator. It is recommended that the parallel axle-reducing and electric gear set should be activated a few hours before it becomes operational, when it is dark or too long, so that the system can reach a low operating temperature when it is required to start. After that, the system used specific manoeuvring oils (mineral oils lSOVG320) for two to four hours. In the case of a parallel axle decelerator and a normal set of manoeuvres, when the gears and pumps are activated for the first time and the oil pumps are disconnected, their oil levels will have to be checked. The size of the oil should be the upper mark of the oil grade up to the scale rule during the time of the gear and pump shutdown。Induction motorOil-routing systems and connections between the gear agency and the oil-routing system should also be welded, corroded and, if necessary, external paints and internal corrosive treatment。

Despite the installation of the F seriesreducing gears, the oil-routing system and all pipelines, and in accordance with the embargo lubrication maintenance rules, the filling of gear oil at the bottom of the F seriesreducing gears with a visceral visceral viscosity of lsOVG320 by the maintenance of the pumpsGeared motora set of gears with axle bearings filled with oil would have to be activated. as this includes the operation of the oil-routing system to maintain the pump re-entry, the re-patterns are cleaned up prior to the initial start-up. note: after refuelling, ensure that the gear unit (the gasket bearing space) is fully filled before the first spring of the lubricant pump. the lubricant motors can then be activated (run: 10 minutes). http://boserlgearreducer.com/product/list-pingxzoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Input maintenance and maintenance of speed-cutting machines