Maintenance techniques for r-series speed-reducing machines

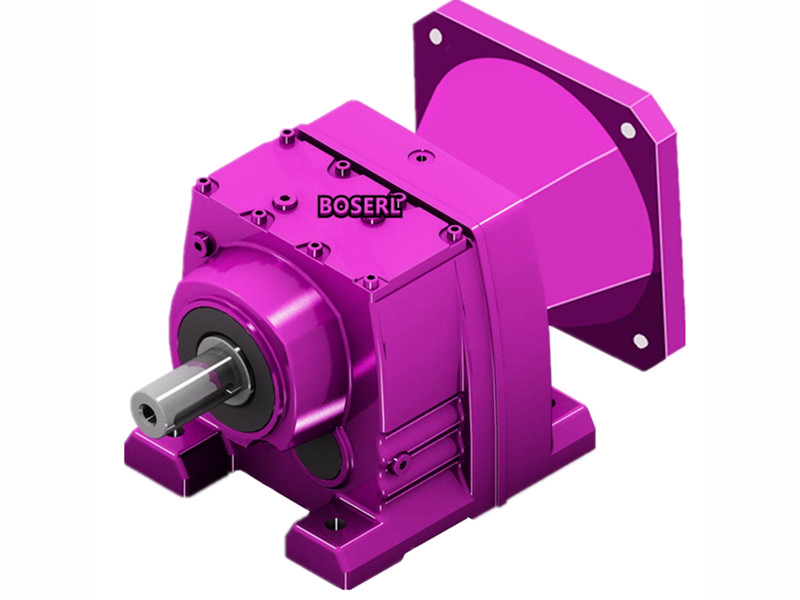

Maintenance techniques for r-series slow-down machines. We'll have to wait a while while we're changing the oil, and when the r-series slasher cools down, make sure there's no possibility of burning, but it's still a matter of keeping the heat warm, because.Three-to-two-hundred-two-hundred-five-fiveWhen completely cooled down, the viscosity of the oil increases, making it more difficult for us to release oil, and it is important to keep an eye on the power to intercept the transmission device and to prevent accidental transmission. Remember, everyone knows that we need to change the oil when we use the R-reducing machine. Boserl, here, tells you that we don’t exactly have to change the first oil exchange to an hour, that we can change it in about 10 days, and that the first one is more important. Then our friend who forgets is going to call an alarm clock or a reminder, and then we're going to check the quality of the oil on schedule for subsequent use, and we're going to use the oil as much as we can, not as many as we can mix it up, otherwise the damage to the R-seriesreducing machine will be very severe. There is also any confusion aboutreducing machines that can be used as a cover for BOSERL sub-editor 2. The immersion depth of the large gears in the tanks is high, but should not be less than 10 mm. Then oursMotor-gear reducerThis is how we use it, and boserl has told our friends in advance: happy mid-autumn festival. So if you have friends, ask, how do you check the oil table? Where do you look? What do you need to know? in the course of our work, when it is discovered that the temperature of the r-reducing machines is above 80 degrees or that the temperature of the tanks is above 100 degrees, and when there is a series of topics, such as the generation of abnormal noise, we need to stop using thereducing machines, and we should check the reasons, and we need to remove the malfunctions before replacing the lubricating oil。

What about the maintenance of the r series? Does it matter? so the boserl sub-editor will teach you how to maintain the brakes before the mid-autumn vacation, and what the techniques are, and then we can use them, so we can go home and scale up the leaveHorizontal reducerScale for lubricating oil: 3. Installation of oil piping. Taking into account the continuing evaporation, wear and tear of the oil in use and the loss of the oil-brokering oil, it is also important to determine the high surface, which is not greater than 1/3 of the drive-by radius (small and medium-sized brakes, which is 5-10 mm above the low surface). 1. In order to avoid mixing of the sludge from the bottom of the oil tank when it is being rotated, the length of the gear to the bottom of the tank shall be greater than 30 mm, which shall be defined as 30 ~ 50 mm. The oil surface thus identified can be considered low. 1. The power supply must be cut so as to prevent electrical contact and wait for thereducing machine to cool (at very hot times). When the exterior velocity of the rotor unit is greater than 12 m/s, oil-spray lubricants should be considered. As with our mid-autumn and long holidays, we need to replace the new oil when the R series is restarted, so that the R series will not cause R series slowdowns to start again for too long a period of time without a good title. If you want to seeGeared motorif it's full of oil, move it to the oil snail. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Maintenance of speed-reducing machines