"Dry" lubricants for a screwdriver gear decelerator

Spiral cortex reduction machine "dry" lubrication。GearbocRare oil lubrication has the advantage of easily forming and adding to the oil membranes, taking heat and flushing impurities, but in some cases the use cycle and anti-oxygen, anti-emulsification, etc. are limited, uneconomical and difficult to seal (especially axle-activated seal). For example, forced return, oil spills, etc. The reactive oil membrane of the gear-reducing motor is a receptor formed by a chemical reaction between the additive and the metal surface, the strength of which depends on the properties of the additive. At present, the swirling gear is used as a rare oil lubricants. The nature of the lubricant determines the strength and characteristics of the film. The adsorptive oil membrane is adsorbed on the surface of the metal by the oil (or oily agent) molecule, and its strength depends on its adsorption. Following gear rotations in the direction of high- loads, the lubrication of the propellers becomes even more important, and it plays an essential role in gear carrying capacity and useful life. "Dry" lubricating with this type of lubricant clearly has the effect of sealing, but the ability of the lubricant to resist grinding and adhesiveness is not sufficientMotor gearedLubrication requirements. In terms of the nature of the oil membrane, it can be divided into adsorbed membranes (also known as non-resorting membranes) and reactive membranes。

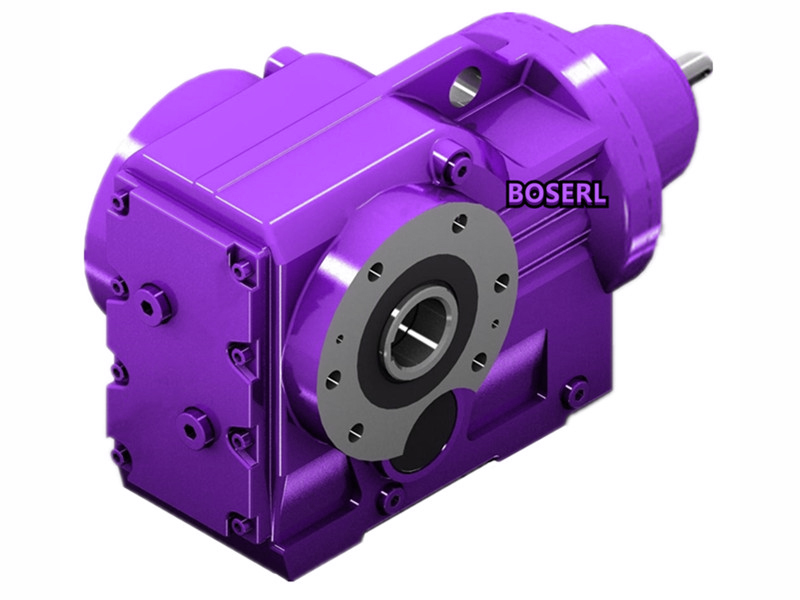

Surface treatment and membrane of the cormorant cortex in the gear-reducing machine: drying the mid-mada sections of gear-reducing gear, in particular the cortex section, with diesel or kerosene, and roasting the cortex to 50-60 degrees Celsius (with heating tools such as air welding or blowlights), with the aim of roasting the oil left in the cone of the contort-reducing cartressor's denture, then cleaning it with diesel or kerosene, gradually removing the rust and the original membrane of the teeth with sand cloths, finely removing the stabbing or scratch marks on the side of the wheel, so that the gear can be polishedGeared motorThe dentures are bright, with a small amount of acetone covered in fine white cloth, drying of the teeth, drying of the ointments or greases to 50-60 degrees centigrade with a paint brush, on average, on the front of the teeth (the gears can be packed in a box), and then squeezing the teeth and brushing them, after manual operation. Metallurgy enterprises are used to refer to lubricant as rare oil, lubricant as “dry”. Surface treatment is determined to be impervious; gear contact is required to be good, with a suitable cleavage and a teeth hardness of more than 230; and each gear-activated bearing is required to be lubricated with lubricant and not to use oil ointment or lubricant as an axle bearing; (b) Without prejudice to the strength of the box, to maximize the peephole on the head of the gear case, with organic glass caps to facilitate observation and membranes; In order to prevent “dry” lubrication failure, when the gear case is packed, it should be sealed in the form of rare oil lubrication, which should be replaced with membrane decomposition, immediately poured into the lubrication without affecting production. The “dry” lubrication in the gear-reducing power plant is a matter of concern: the initial membrane process and long-term membrane screening is assigned to a person, a documented card is developed, documented and the subject is identified for timely processing. The lubrication of the gear isSpiral cone gear deceleratoressential components of the movement. gear-reducing motor lubricant has been used as a “structural material” or as an element that cannot be ignored in the design of gear-reducing motors. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: "Dry" lubricants for a screwdriver gear decelerator