Analysis and resolution of oil spills in the parasol gears

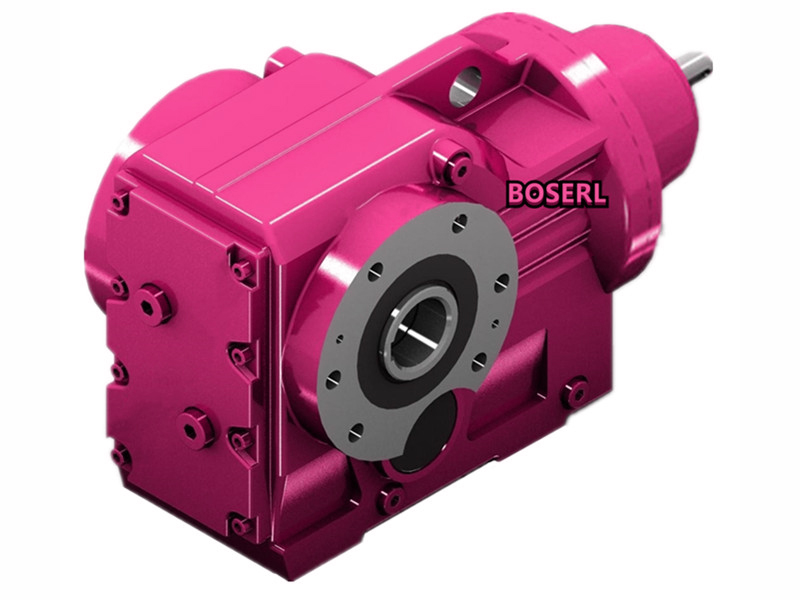

Analysis of and solutions to oil spills from the turbos. An umbrella gear-reducing machine is an independent, closed-constructing repertoire between an electric and a working machine, and in actual production, gear-reducing machines easily spread to varying degrees of oil spills due to a poor working environment, heavy loads and frequent start-up of equipment, which ultimately reduces their useful life. The survey shows that:Double-polar slowing machineThe main areas of the oil spill were in the observation hole, the side of the box and the input and output axis. In response to the above analysis, it is common practice for us to address oil spills from the paragus gears: the main reason for the spilling of oil from the paragus is that the pressure in the trunk is too high, so that the gear-reducing motor should be equipped with a suitable vent mask to ensure average pressure, which should be in the right size and can be felt after a few minutes of operation. If the pressure is very low, then the vents will not be large enough to use large wind vents; the oil leak will be avoided by selecting a high-quality oil seal, which should be fully sealed, the interface and the axial head; the flow: a rewinding tank in the middle of the axle bearing, with a gap at the end of the main vent, and a gap in which is being applied to the repulsing tank, so that the excess lubric oil gap and the flowing tank will be used; and the process of testing:Geared motorAt the time of the test, the procedure must be performed in good faith, the oil seals must not be turned back, the lips must not be damaged, the outer edges must not be deformed, the springs must not be removed, the face must be cleaned, the seal tape must be painted on average and the amount of refuelled must not exceed the scale of the oil scale; wipe : Gear-reducing power station static sealing points can be reached in permeability by management, but the mobile sealing points, due to the ageing of the seals, poor quality, inappropriate assembly, and the high level of roughness of the axle surfaces, leave a small leak in a secure spot because of the poor working environment and the fact that coal dust is glued to the axle and appears to be oily, so that the oil stains on the axle need to be cleaned up in a timely manner after the equipment has ceased to function。

The main reasons for the oil spill in the turbos are as follows:Motor geared(a) Unfair design: an umbrella gear-reducing machine is not equipped with a vent mask and cannot carry an average pressure, which will cause a constant increase in pressure and a leak of oilAn umbrella gear-reducing machinein the course of its operation, the oil tanks are heavily disturbed and lubricated oil is splattered inside the aircraft, and if there is too much refuelling, a large amount of the lubricated oil is stored in axle seals, patches, etc., which can also cause a spill of lubricant. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Analysis and resolution of oil spills in speed-reducing machines