Reasons for heating caused by the lack of fuel supply for axle slash gears

The reason for the heat is the lack of fuel for the axle slasher. Through six months of practice, it has been shown that after the transformationbrakes motor-reducerThe extended useful life has reversed the long-term failure rate and the backwardness of technological economic indicators, such as output and capital, and has saved significant time for testing and raw materials, reducing downtime and smoothing the axle gears. In addition, there are no fuel tanks on the axes of the same axle gears, the second, fifth and sixth axes, which are supplied with oil by the oil sheaths outside of the axle bearings, while there is only one oil spot in the oil tank, which can easily cause oil cuts at the point of installation by jamming in miscellaneous items such as sealed glue, remodelling the oil sheaths, and changing the oil spot to an average of eight oil spots to provide for more oil. The compatibility of bearings with axle and axle bearings depends on the size of the load, the heavier load uses a larger excess, the lighter load uses a smaller excess, and it is also important to adjust the axis gap during installation. The lack of fuel supply in the use of the same-axis tilt gears is the main reason for the fever, and each bearing on the gear-reducing motor axis has two oil points, one in the end and the other in the outer end, which, if connected only to the external oil point, is sufficient for the gear-reducing engine to supply the oil, but not sufficient for the oil, and if the link is only a real oil point, as a side wheelGeared motorAt the time of the stand-by installation, the real-element oil spot could not provide oil to the bearing above each axis。

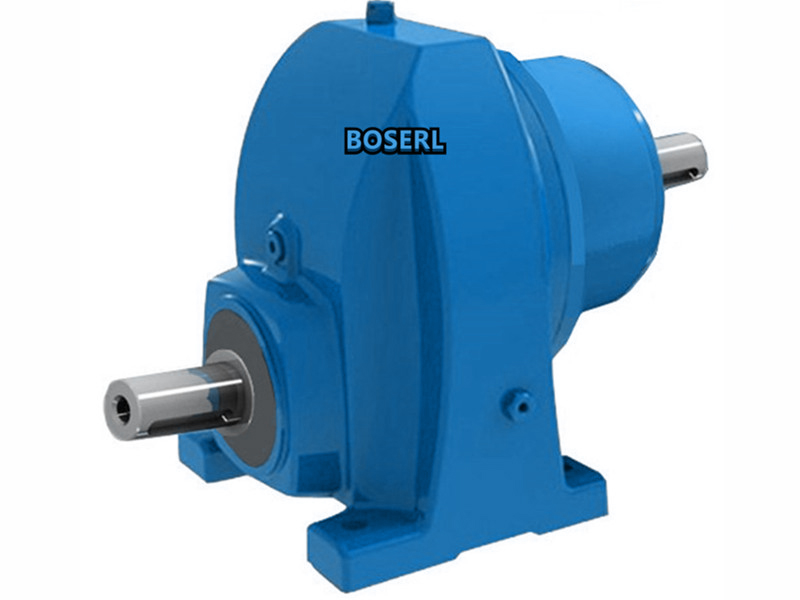

The accuracy or absence of the installation of the bearings, and the co-operation or not, are the hubs of the fever, and the loss is exacerbated by the excessive fever of the bearings as a result of the small gap in the moving bearingsMotor gearedThe outer circle of the bearings and the perforation of the perforation are too wide, and the scrolling of the coats inside the perforation leads to a fever of the bearings, while the internal and external dimensions of the moving bearings are made of a scale bus, and the inner and axle of the bearings, the outer circle and the perforation of the perforation are loose and can only be achieved by controlling the periphery of the neck and the periphery. The axle gear brake is a mechanical device for the transfer of motion and power, because it has the advantage of having a high range, high transmission power, a right rate of transmission, and a long life. It is an essential moving component of most mechanical equipment. In terms of trends, the gear-reducing motors are developing towards miniaturization, high, low noise, scale and serialization. However, the presence of the same-axis slash gear reduction machines, because of their installation and maintenance, would significantly reduce their service life, as is the case with the high temperature of the axle gear reduction machines and the occasional occurrence of accelerator bearings, which are the main obstacles to production. This paper goes into an in-depth analysis of these topics, identifies the reasons for the fever of the gear reduction machines, proposes improvements and specifies the relevant knowledge of the gear reduction machines. Motivation: through a careful dialysis, the reasons for the retrofitting of the gas route of the gear-reducing motor, the connection of two gas routes to the main road, and the provision of oil to the two bearings, respectively, will be sufficient to provide oil to each of the axes, both in standing form and in the bedroom, and will not increase the temperature of the gear-receiving motor because of the lack of fuel. And..Double-hole output reductionthe oil routes, some of which are attached to the oil spot, and others to the oil spot, result in the loss of the oil at the vertical installation, which leads to an increase in the temperature of the bearings, the burning of the bearings, which is not easily detected at the time of inspection, and severely constrains the development of production. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Reasons for heat fever due to inadequate fuel supply