duct tape transporter snail snail speed-reducing machine cooler system design

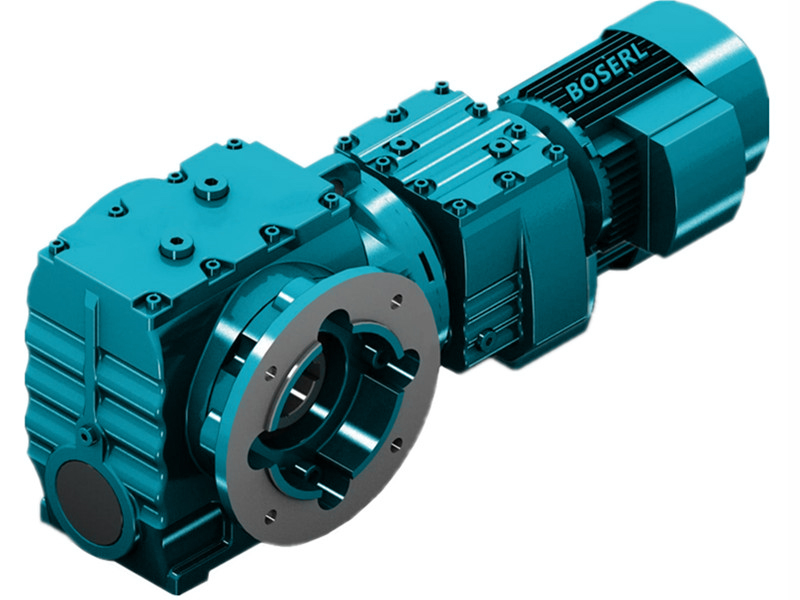

The duct tape transporter snail snailreducing machine design. Connect the fuel pump and cooler switch to the belt control system, based on the remainingThree-hundred-thirty-eight-fiveThe temperature level is fair and the operation of the pumps and coolers is notified. Production of oil filters with a size of 376*0, internal placement of oil cores from used cone breaker stations, a bolt-link sealing of the lower part of the unit with home-made flanges, and a tooth-leaved upper and lower part of the leaching unit for the connection pipe; and a two-storey platform with an overall framework of 200 slots of steel welded to 4 m*1 m*1 m, with steel panels laid on the upper and lower parts of the platform for the installation of three wind coolers, three oil pumps and three oil filters. Implementation programmes and routes: first, the removal of cooling water tanks, which were originally equipped with a cooling system for the head of the belt, and the emptying of the water cooling towers to accommodate the installation of a cooling system platform. Motion: The snail snail snail cooler cooler cooler cooler cooler system consists mainly of three-segregation motor pumps, wind-cooler chillers, oil filters, pressure-resistant pipes and valves. It works in such a way that, under the suction of three-segregation gas pumps, the hot oil from the snail snail snails reaches the wind-cooler at the bottom of the slug, heat exchange through high- active air as a heat-exchange medium, heat is removed through air and then the cooled working oil is re-entered into the snails, which constitutes a cooling and retrofitting route for the lubricantsThrough-hole shaft reducerThe purpose of the cooling of the heat-working oil and the installation of oil filters at the bottom of the tank, ensures the oil requirements of the snails for reduction and avoids the damage caused by impurities to the moving gears。

Steel wire duct tape transmitterSnail scaldingThe operation of the wind cooler cooler cooler cooler cooler cooler system has a clear effect, and before the wind cooler cooler is retrofitted, thereducing machine can operate at a maximum temperature of 65 degrees under the combined effect of hot weather and high loads, with long-term operation at high temperatures endangering the safety of the equipment. Three wind coolers were placed on the upper platform, three oil pumps and three oil filters were placed on the lower platform, and the chillers were connected to the zinc plating and pressure-resistant rubber pipes, respectively, and the pumps, filters and snails slowed in, out of and out of the oilway constituted the Lubricant Tanker Return Road. After cooling cooling cooling and cooling, the snail-wheel-reducing machine reduced its flat temperature to about 45 degrees, ensuring that the equipment operated safely under high load capacity and heat. The steel-lined duct tape transporter, which has long intervals, large momentum, high bandwidth, etc., is the preferred equipment for the transport of ore as a shredding system, and a tape-coated transmission system contains particularly during the summer, with three snails operating at temperatures above 65 degrees Celsius, which reduces the lubrication effect and increases the wear of snail snails, resulting inGeared motorthe damage, which increased the frequency and cost of maintenance of the equipment, severely affected the safe operation of the equipment and forced its cooling through the axle winder during the prior period, as the cooling area was small and its effects were not significant, leaving the equipment in a chronic state of insecurity. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Slower cooler system design