Analysis of the causes of wear and tear in the snail snail snails

Analysis of the causes of wear and tear in the snail snails. The snailretarding box is a high-up part of the cut, but it's also a swing of the cutSlow down, oneThe structure, which is part of the retrieving hub, affects the ability to intercept and the smoothness of the amputation of the whole machine. In general, the life of each of the air liners is about half a year, with individual cases having a useful life of only 1-2 months. However, in practice, there are often rigid layers of coal, such as clamps, which are sometimes used in practice. The damage to the repulsive structure of the retort is very large, and the equipment has been in full or overload operation for many years, leading to the fragmentation of the liner grinding or snail-retarding machines, which are more closely attached to the detorting tank than the amputation head. In order to ensure production progress, the hub is to strengthen the agency ' s reversibility and to repair it in a relatively short period of time, we will look at the gearing of thereducing aircraft. In any case, every faulty subject in the production process should be resolved as quickly, as conveniently and as reliably as possibleBig-rate slow-down machineThe efficiency of the tests allows for the efficient and normal functioning of the excavations in a relatively short period of time. The core of the hub for the extraction of the work surface is the dig-in machine, which has high-intensity, functionally reliable and anti-diversion capabilities, and is used for the digging of large-diggered coal and semi-coal rock alleys。

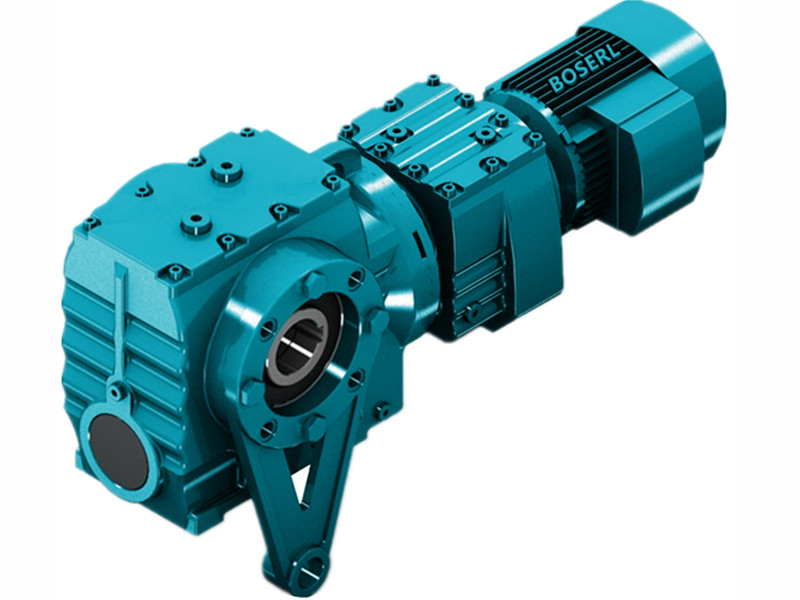

Damaged shredding, squeezed under the lead of the axle, will cause an inner hole and a snailGeared motorThe wear and tear of the axle is no longer capable of assembly at the time of the inspection and the position needs to be processed for reassembly. Improvement measures: In order to reduce the failure rate and extend the service life of the brakes caused by liner wear, it is necessary to effectively control the wear and tear of the liner, starting with the need to ensure, in day-to-day maintenance, the good sealing of the hoods of the scalding tank and the regular maintenance inspection work, the timely repair and replacement of the worn liner, and to avoid, to the extent possible, secondary damage to the cores of the retrofitting machine so as to ensure that the work of the liner is not impaired; and the use of a number of protection measures, such as dust-clading and shielding measures, to protect the axle from the loss of the liner and to prevent the loss of lubricating resin caused by the direct contact of solid particles and the slag with the liner. The frequent replacement of the liner severely affected production progress below the well. Because of the horizontal and longitudinal swing of the excavator when it works under the well, the amputation of the chest is both horizontal and vertical, and the line is highly susceptible to damage when the excavator touches a hard coal layer, such as quartz, which is influenced by an imbalance in the axis and direction. While the excavator works in hard coal formations, such as pegsSnail scaldingboxes are highly susceptible to liner grinding or box breaking, leading to interference between the box and the lift hydraulic tank. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Analysis of the causes of wear and tear in the slowing case