Reasons for and solutions to the frequent damage to snail snails

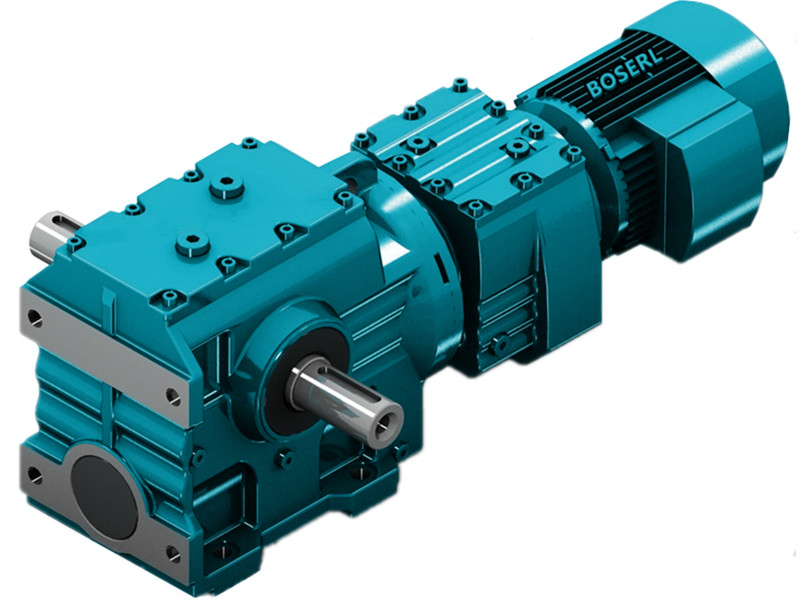

Reasons for, and solutions to, frequent damage to snail snails. Improvement process: The idea is to address the small balance of the swing spring, thereby reducing itGear with motorworkload. if the snail snails of the snails of the snails need to be worn down and repaired, first, the steel collars should be placed in the lowest position, with a roller to the bottom, and the scalding levers should be removed from the condensed cams, and then the scaffolds of the snails should be removed, the screws on the feet of the snails of the scaffolds could be removed, the bearings on the scaffolds of the scaffolds of the snails of the scubbles would be removed, and the scramblings would be pulled out slowly at the end of the snails, and the scowders would have to be hit by rotation or damaged. at the right end, a 14 mm screw is processed on the bottom of the head, and at the right end of the plate, a 14 mm diameter roundhole is drilled in the middle of the plate, and the plate is attached to the bottom of the plate with a screw. two- main transmissionGear motors, synchronized gear bands, effective noise reduction. High-precision main axis is used to operate smoothly and securely. The steel plate is processed at the left end of the chain, which is linked at the lowest point of the lifting or lowering leverage (the steel collar is also at the starting point because of the heavy wringing of the spring). A tiara machine, which is used in a tiara of pure cotton or filament, and in a tiara of tiara, etc., which can be swiped. The lifting and down-leveraging process after driving because of the low impact of the spring-coated steel plate, when the left end of the spring-coated steel plate is brought up, increases a downward pull below the lift-down lever (the repulsive force of the spring-coated steel plate), then wrings a fixed screw on the right-end steel plate, and it is appropriate that the convective rotor, which regulates the rise of the spring-down lever, is in immediate contact with the dent of the forming cam。

This is usually a broken bearing on the snail, which opens the lid on the lower snail, pulls out the oil seal, makes sure that it is not broken, then knocks on the snail axle and pulls out the snail. The reason for this is the small balance of the swing spring. After some time in use at a textile factory, it's spread outGeared motorFrequent damage. In the form cam moving sector, a snailretarder is used, with no disruptions, to ensure that the veil does not take off when in a high- cylinder. Heavy lift and landing systems, such as leverage, are transmitted to snailreducing machines, snails are too resistant to snails, friction factors exceed normal values, protection of the oil film on the snail's surface is scraped out of each other and does not work lubricating, making snails in snail-reducing machines difficult to drive, without lubrication, to control up and down the heavy lift and down sectors, which significantly reduces the life of snail snail snails, increases their consumption and affects production, while creating a danger to veil quality. Through a careful analysis of the working methods of the springs of the wrinkles, which were improved and tested on the ceremonials, the improved balance, the smooth operation of thereducing machines and the loss of the acoustic noise, the failure of steel-collar slabs and the subsequent disappearance of the rewinding of the thorns, which reduced the rate of bad car traffic and the loss of the head in the millenium, improved the quality of the veil. It's a lot easierHorizontal reducerThe sustainability of the various components, the increased useful life of the various components, the reduction in the consumption of machinery and materials, and the reduction of the labour intensity of maintenance workers, as well as the reduction of the main electric power load as a result of reduced resistance between gears, will also have a positive effect on the protection and conservation of the main electric power. Detailed implementation is the addition of two 60 mm wide, 7 mm thick and 260 mm long, and 0 mm long, respectively, under the lifting and landing levers, arc to the top. The resilience of the spring steel plate at this time passed the parking test, with a value of 170daN and a small value of 95daN. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Reasons for frequent damage to speed-reducing machines