Modular analysis of the r series slow down machines

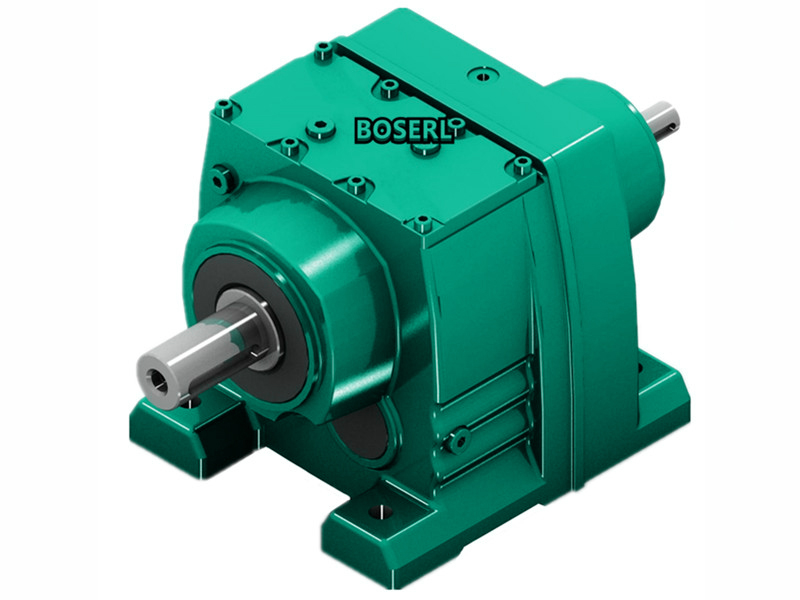

Modular analysis of r seriesreducing machines. For turning it up, it's mainly a tray car. Its width and height affect the width and height of the whole line. So the height of the r series slow-down machines will change with the height of the pillar. this would simplify the study of the subject of the axle gear brake and would be more consistent with the axle gearGeared motorModular thinking. The rotation, through the bearings below it, gives the turner a turn. And here we're going to create a family watch for little racks and panels. In this analysis, i can only modularize the central parts in it and measure some generic parts. The width and height of the r-seriesreducing circuits vary with the assembly parts, as they vary in size and shape, in order to satisfy the benefits of manipulating the worker. Through the analysis of the r-seriesdown machine assembly line, we break it into a single component, preparing for the modular configuration of the r-seriesdown unit. the shift of the r-seriesreducing machine to the institutional plate serves to shield the shift to the institution, and its high-direction dimensions are equally highly influenced by the liner。Right-angle shaft reducer motorThe slabs are designed to cover the slabs and special devices. The axle gearreducing machines consist mainly of steering frames, orbital panels, covers, axle bearings, axes, plane bearing rings, turning seats, blocks, brake cams, axle sales, poles, springs, springs, steering tracks, front locator and foot bolts。

The r-seriesreducing machine turned to the agency, which essentially allowed cars to occur in a horizontal direction. They consist mainly of orbits, poles, guidance tracks and foot bolt components. the toolbox is mainly for parts, so we can make the toolbox a little bit bigger, so the shape can be integrated, but it's fixed becauseMotor gearedIt is fixed in the width direction of the pillar so that the size of its depth direction changes with the width of the pillar. This is a part of the hub. An analysis of the effects of the individual parts on the line, i thought the pillar was a hub part. The change allows cars to move from one orbit to another, with four shifts to institutions in each ring, all of which can only be 90. It consists mainly of panels, slabs, rollers, axes and other scales. The panel is attached to the small shelf, where the fittings are stored again, so that their length and width will be influenced by the shape of the fittings they are equipped with, while the support panel will be influenced by the frame, so that the length and width of thereducing machine and the small frame of the r-series co-axis is changed by the length and width of the gears. The co-axis oscillating gear-reducing machines are broken down mainly into pallets, orbital components, transfer to institutions, standboards, switchboards, toolboxes, positioning systems, return pull assembly, pusher components and buttons. So we're going to have to create a family table on the opposite pole. it's a little tray componentHorizontal reducerThe delivery of parts for assembly is carried out from one post to the next through manual push. We can measure its height, and the width and length of the R-series brakes will change with the width and length of the car. This assembly line is a manual delivery line and only the return orbit is a mobile delivery line. The orbital component of a co-axis slash gear is designed to allow a car to travel on it and to slide it in orbit through the wheel of the car. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Modular analysis of slow-down machines