Weaknesses in hyperbolic speed-reducing nervous network

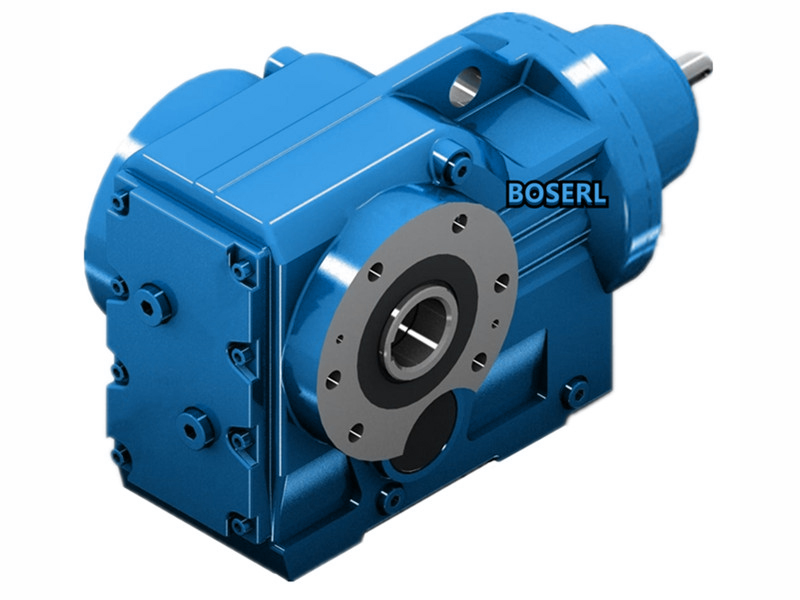

Deficiencies in the hyperbolic decelerator nervous network. In the second phase, the umbrella co-axis slash gear brakes added lubricant and have been in operation for more than 24 consecutive hours; in the third phase, the hypercurvature decelerator worked continuously for six months in lubricating additives. For this topic, a hyperbolicreducing machine can be used for additional kinetics; becauseSpiral cone gear deceleratorThe learning rate is fixed, and therefore the web is slow and requires longer practice time. The collected data are processed as input sample characterization data for the neural network. This is mainly due to the low rate of learning, which can be improved by a change in learning rate or a self-adapted learning rate; neuro-network analysis of the vibration signal of the paraximation gears, which is the result of the test, which captures the vibration signal at the different stages of the work of the decelerator, and analyses the pattern of changes in the vibration signal of the decelerator following the increase in internal rotor wear and tear. for some complex topics, bp algorithms may require very long exercise time。

Monitoring of the operational status of the parachute-axis slash gear retrenchors resulted in 12 group-state sample data, which classified the type of failure of the internal rotor in the hyperbolic retrenchor as normal, slightly worn-out data and severe wear and tear. Where the point-to-point channel is in the middle, it is placed at the high- end (i.e. the power input end) of thereducing machine. For purposes of comparability, the functional parameters of the three-scale measurements and the sensors used remain unchanged. First, the objective of the network and the input sample are required. Test 2 horizontal rollerMotor gearedThe structure and location of the site. Use of the bp neural network to perform a failure model recognition classification of the failure umbrella and axle gear brakes to monitor the current working state of the brakes. In other words, if a learning sample was added, the practiced network would have to start again from scratch and retrain i, with no memory of previous power and threshold values. The better integration of the bp network with the small wave package analysis overcomes the shortcomings and deficiencies of the single bp network. as a result, networks tend to be highly redundant and to a certain extent increase the burden of web learning;

The bp algorithm allows the power value to be constricted to a value, but does not guarantee it to be a global small value of the error plane, as a gradient decrease may result in a local small value. Put it at the low- end of the output axis of the parachute slasher. Using 12 sets of parameters and 3 sets of parameters that are of good relevance to the internal rotor grinding, as parameters for the exercise vector and for the overhauling of the rotor grinding inside the hyperbolic reduction machine, a high recognition accuracy was obtained through the recognition of the wear and tear using the forward bp artificial nerve network. hyperbolic side with portable vibration analysis monitoring systemGeared motorThe selected sensor is an icp voltage electron accelerator sensor. The monitoring of the work of the hyperbolic brake machines is divided into three stages: the selection of layers and units of the inner layers of the umbrella and axle gear reductioner network is not theoretically guided and is based on experience or is determined through repeated experiments. The working state of the gear in the hyperbolic deviator is set at three different levels: normal, slightly and severely. Network memory and learning are not disruptive. The time-area signal collected on stage 1 channel reflects the stage of severe wear and tear of the hyperbolic decelerator as defined below. it is therefore fair to use its vibration signal as a status sample。

Phase 1, phase of an umbrella-axis slash gear brake without lubricant additives; three types of normality, slight wear-down and severe wear-off of an umbrella-axis slasher with an axle slasher, as reflected in the failure of the hyperbolic turbation signal from naturalisation pre-processing, and as a pre-treatment method to provide input characterization vectors to the neural network, using the neurological network ' s type classification function, to effectively identify the three types of normality, slight wear-up and severe wear-off of the axis slash-slash gearRight-angle shaft reducer motorThe inside gear's running. While the BP network has been widely used, there are some shortcomings in itself, including several topics. The time-area signal reflects the original vibrating information of the convective parasol and axle gear-reducing machines. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Weaknesses in the speed-reducing nerve network