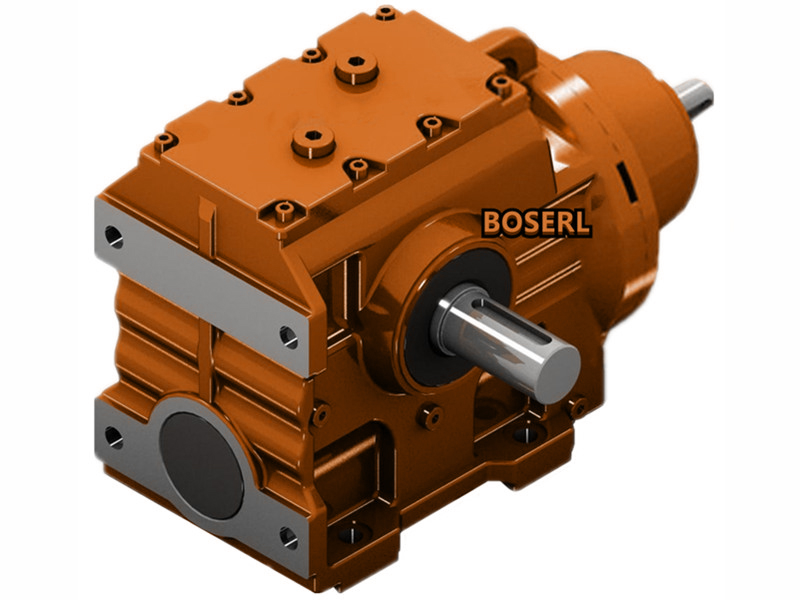

Improvements to the s-series speed-reducing output-end sealing structure

Methods for improving the sealing structure of the output end of the S seriesdown machine. Detailed design and structure are as follows: internal “o” rubber rings block oils in large sectors, and a small amount of leaked oils are blocked by the throttle effects of the cracks through the maze. In fact, the use of the above-mentioned sealing structures alone is not optimal, but much better when combined sealing structures are used. - For impactBig-rate slow-down machineThe factors for the end-of-out sealing are identified and improved, and snail brakes are widely used in metallurgy, lifting, chemical, textile, light work, etc. , and are used more frequently. There are individual users who generally reflect that the real oil spill from the s-series decelerator output is severe and affects normal production. the detailed design and structure are as follows: the outer side of the bearing is designed for a static endring, which is the so-called labyrinth with several grooves on the left side of the static ring (near the output end), a hole in the maze for lubrication, a skeletal sealing of the skeletons on the inner end of the ring, and an active endring (similar to several girdles of the car) in conjunction with the static end of the ring, a moving end ring closely aligned with the output axis, rolling with the axis, incorporating a proper amount of grease into the maze through the oil hole on the giraffe, using this combination structure, even when used in a very large dusty environment, has a proportionate seal effect, and these are available on the marketGear motorsthe ready-made products form maze seals. thus, sealing should be effective not only in safeguarding the oil’s own activities, but also in focusing on the reduction of the sealing effect from dust. improvements in fur sealing: the major drawback of this structure's sealing is wear and tear, a combination of a “o” rubber ring plus maze sealing to address this topic. if necessary, an oil spill was made under the maze, so that the excess oil in the maze could be released。

(a) the s seriesreducing machine output end will require the appropriate anti-dust protection, which will inevitably lead to a defined dust during the operation of the snail snail-reducing machine, which will enter the containment unit and lead to unnecessary wear and tear of the internal gears, bearings, etc. , which will lead to the failure of the s seriesreducing device; second, the dust and lubricant are fully mixed under a gear mix, creating a large mix, which affects the lubrication effect and activity of the lubricating oil, and is therefore not conducive toHelical-worm gearmotorThe axle of the secret sealing device rolls down the sealing effect, followed by a dusty, too many gathering sessions, which resulted in the blockage of the smooth flow of snail snails and lubricating oils and the suspension of the entire sealing device. Combination design of the snail snail nmrv output real seal structure: in the case of the traditional seal structure, more use is made of the above-mentioned oil rings, skeletal devices, etc. , to complete the sealing. Currently, the axle sealing of snail snails uses more of the combinations of maze seals and skeleton oil seals, which can be divided into radial mazes (sectional axle bearings) and axle (whole axle bearings) depending on the type of section of the s series axle bearings. Therefore, there is a need for purposeful improvements to the commonly used s-seriesreducing output end sealing structure. The advantages and disadvantages of these seals are described below in relation to the improvement of the sealing structure at the output end of snail snails. inspection needs to be carried out in a comprehensive manner with regard to the need for tanks in the oil recovery sector to be properly configured for width and depth, so as to ensure a good flow of oil; special attention should be paid to the use and cleanness of lubricating oils for the export of a true seal; all open space within a sealed device channel should also be scientifically processed; snail snailsGeared motorIt's got to be controlled, and it's got to be on a scale. The current sealing structure consists of sealing with a fur ring, sealing with a skeleton oil seal, full use of a leaching ring to process a genuine seal out of a S-series gear-reducing vessel, maze sealing, and dry well sealing. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Ways to improve the speed-reducing output-end sealing structure