Talk about the r-series speed-reducing box repair technology

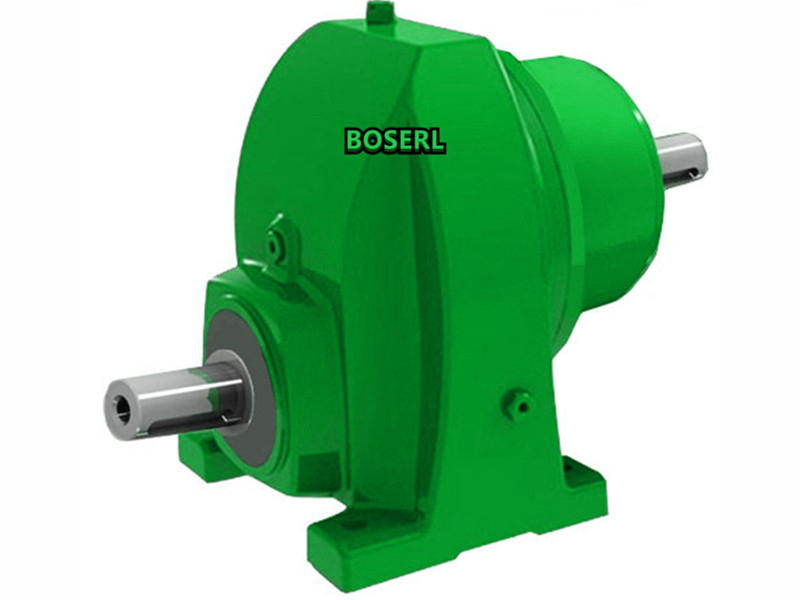

A brief discussion of the r-seriesreducing machine box-hole repair technology. Below is a relatively simple method of repairing the cartons of the tilt gear. step one: disassembly, after the r seriesreducing machine has been repaired, remove all the bolts of each mouth and then take them outGearbocThe axle covers are removed, the gear axes and bearings in the case are removed, and the case is cleaned with kerosene, especially with regard to the cavity of the case, the upper and lower part of the mouth, the upper and lower part of the case, and the presence of gutters, rows, pits, etc. And the way we do it is to remove 0. 3 mm of each of the upper and lower cavities, so that the central hole of the cavity drops down and the natural processing of the cavity comes out. In the case of the r series ofreducing cases, which can be broken down as a result of the fragmentation of the case, the cortex wear and the arc of the case, which is linked to the electric power, the r series ofreducing machines are in the high- rotation sector. In the case of my contacts, the subject matter of the r series ofreducing machines, which are being repaired, often cross-referenced to the position of the two-axis bearings, has led to a series of gutters, channels, pits, etc. In the area of the axis ii, which are shallow in depths, but if not addressed, even if new bearings are replaced, the r series ofreducing machines will not function properly. if we're going to change the traditional gear-retarder box repair method, we're going to need to get to the processing gear by changing the center of the upper and lower sideGeared motorThe purpose of the box hole was a significant improvement in the efficiency of the recovery of the r-seriesreducing machines and the avoidance of the traditional welding process by which the technical requirements of the foot drawings could be obtained directly through mechanical processing. A line was then drawn, the size of which was sized by the drawing, followed by a perforation of the hole in the upper bed, i. E. The entire restoration of the box. step 4: mechanical processing。

Step threeHorizontal reducerBased on the scale of wear and tear, motors determine the size of the process, and it is known from the scale data that the three holes are worn to increase the size of the perforation, and that the outer bearings can easily cause the axle bearings to move in this environment, since the wear is not too large. In order to restore the large perforated hole to its original size, the traditional method is to weld the perforation of the perforation, and to poach the perforated bed. The volume of processing of upper and lower hulls is determined on the basis of the degree of wear and tear of the perforation, which is half the amount of wear and tear of the perforation, since the gears of the r series are as large as the space between the gears and the bottoms of the hull, so that the whole centre is reduced by one to two millimetres, with no impact on the overall assembly of the tilt gears. At the r-seriesreducing machine, the case is the main component, and wear is common, so.Tilt gear brakesthe rehabilitation of the boxes became a priority. once the residual amount of processing has been determined above, the upper and lower surfaces are processed on the bed, the lower and upper surfaces are processed, and a measure examination is performed, bearing in mind that the upper and lower surfaces must be processed in such a way as to ensure that they are flat, and that the upper and lower parts of the container are reinforced by bolts. the second step: to measure the amount of wear and tear, to clean up the upper and lower body and dry it up, and to combine it, this step will require only that the upper and lower parts of the container be joined, and that the bolts of each mouth be tightened, and the perforate sizes be measured, comparing the actual size of the scale with the drawing requirements, and calculating the wear and tear. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-deficit box repair technology