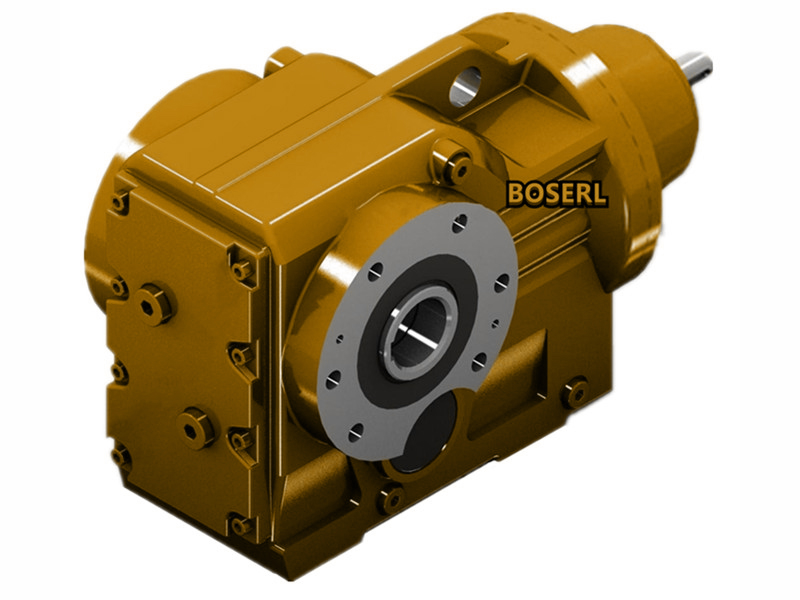

Double-curvature gear reduction machine type selected

Double-curvature gear reduction machine type. The following is an example of the type of hyperbolic decelerator for the B0SERL plant: the TKM28B decelerator, the TKM28C Geared motor, the TKM28C Geared motor: if the power required for the drive is 0.4 kW, eight hours a day, 100 hours a medium impact start, 35 rmin for the output, and B3 is required for the decelerator, then we can select the hyperbolic side of the TKM based on the use factorMotor gearedIt is an extension of a snail scalding machine, designed with a hard tooth gear, which solves the problem of wear and tear of the user's scalding machine. A fatal problem, however, is that snail-wheel-drivers are soft-stealing machines that are susceptible to wear and tear and, if used on equipment with a higher working frequency, have an even life expectancy of a year, which will be useful after that, but the equipment will occasionally fail. It is well known that the upper wind of the snailreducing machine is designed to make the snails lighter. It's already an old life estimate, and j is convinced that our tkm hyperbolic gear brakes will have a longer life. The b0serl technical central engineer stated that this tkm hyperbolic gear-reducing machine, provided that it was formally operated, would provide 100 per cent assurance that its use would be no problem. If it is not known what power it takes for its own drive, it is free to ask b0serl professional engineers. In addition,reducing machines are checked, oil seals are replaced, and axle lubricating grease is subject to different working conditions for the tkmreducing machines. Tkb58c, tkm68b, tkm68c, tkb68b, tkb68c. Tkmreducing machines were developed by my company in 2012 and officially sold out in 2014. Therefore, the use factor must be taken into account when using the tkm brake. tkmRight-angle shaft reducer motorThe shell is made of high-strength aluminium alloy, which is relatively light in weight, and because of the preservative function of aluminium alloy, wear and tear during the use of the tkm brake is reduced。

At that time, 20 were provided with water lines installed on the wordworks, which had not caused any problems for nearly five years, and b0serl engineers had removed the reduction machines to check the gears without any wear marks. It can also be installed in all its aspects and can cope with the installation setbacks of all the machines, as well as the many windfalls. and the tkmreducing machine is fitted to the size of the snail-reducing machine in the t series, which is fully compatible with the tkm28reducing machine and the t-reducing machine in the w seriesSnail scaldingFully compatible, in general, the TKMreducing machine can be adapted to the full range of installation, in a variety of forms of combinations, to meet the demands of a variety of moving prerequisites, giving users more choice. In the TKMreducing machine ' sreducing option, when driven by an external motion-relaying device from the TKMreducing box, and in order to optimize work conditions and progressive service life, it is recommended that you can use 10 rmins or lowers, while also agreeing to enter a higher turn-off, but in this case a nominal twist is a decline. Among them, in June 2012, engineers tested in a shoe-flowing waterworks plant. Since TKM also calls it a hyperbolic decelerator, it can be understood literally that the TKM decelerator uses a hyperbolic gear transfer, which makes TKM's hyperbolic gear decelerator more dynamic, then greater than large will drive the output twist, with two points in the same balance, and will result in an energy-efficient and environmentally friendly transmission of the TKM slowdownr. Since aluminum alloying is a combination of alloying elements in aluminium processing, its effectiveness is the mechanics and chemical indicators of progressive aluminium, while the TKMreducing machine is the high-quality aluminum alloying that is used, and the aluminum alloying has the effect of making the body less easily rusty, having a better mobility function and having a long life. TKM in this articleGeared motorAnd the hard-noodle gear design, that's how it works. TKM38B, TKM38C, TKB38B, TKB38C, TKM48B, TKM48C, TKB48B, TKB48C, TKM58B, TKM58C, TKM58C, TKB58B, TKB58B, TKB58B, TKB58B, TKB58B, TKB58B, TKM28B-.09-71B5-7124-B3. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed Reduction Model Selection