What are the requirements for the gear-reducing motors used on the rotation platform?

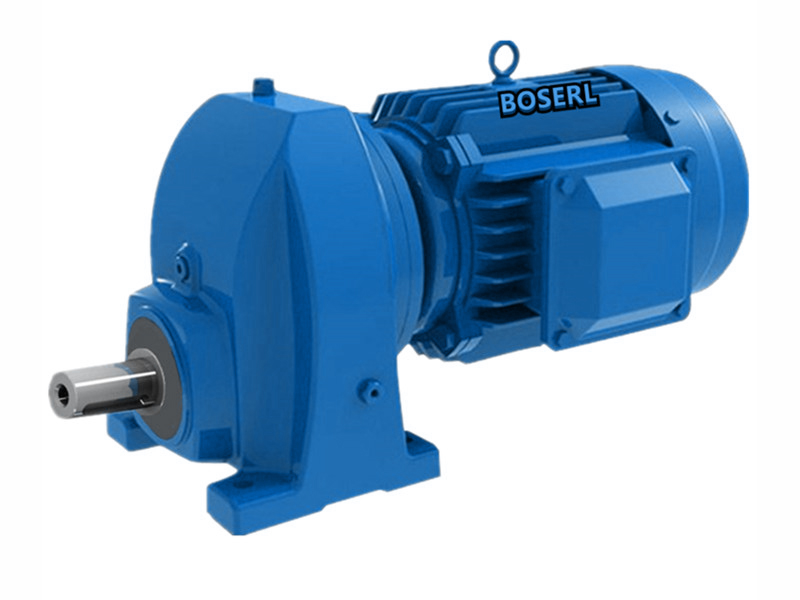

What are the requirements for the gear-reducing motors used on the rotation platform? The use of such a rotating stand would have to be smooth, so it would be necessary to ensure that the user, after combining thedown machine and the electric machine in its use, has a more fluid mode of running the stand, and that the entire process of running the stand is almost in a circle, so that the output axis or the output hole of thereducing machine used in this case is a forward-looking form. Because of the weight of the boothMotor gearedOr the size of the output twist that can be formed by a snail reduction machine. And what he needs today, the first user, is areducing machine, which in the process can make a stand of up to 1 ton operational, so what should be required at this time? How do you choose a very appropriate model to use in this? This is a rotating stand that we normally see. The power machinery installed at the lower end of the stand may be a gear-retarder or a device such as aretarder to drive the operation of the equipment. If the depth is sufficient, a straight-line r-series gear-retarder can be used, but if the depth is insufficient, a straight-angle-retarder will be needed to save space for installation. So what we can choose at this point is a s series ofreducing machines and.Motor-gear reducerI don't know. These two series of slow-down machines are better. if the output of the k-reducing machine doesn't have enough twirling, then the drive counter won't work

A growing number of producers are willing to offer a 360-degree product display to users, so a mechanical, user-friendly product is needed to rotate in the process. Because of the relative weight of users, we now have to determine that the stand weighs 1 ton or the gallery plus the display. We used to use straight angles more often in some of the previous rimsGeared motorAs he saves space for installation, he also has a better internal structure to counter the complex work environment. While users have not provided relevant parameters, we can consider some practical uses. Under the stand is a power-providing device in which the weight of the different demonstration products is estimated and then the size of the actual operational requirement is estimated by weight. In choosing to use four series ofreducing machines, we feel that they are better suited to different environments and are recommended to users. If it were all heavy, then a detailed use could be considered. At this point, if the total mass of thereducing engine is 1 ton (1,000 kg), the combination of thereducing machine and the electric power is enough to make 50 onm, so the required twist is not so big that we can choose from these parameters. we also need to know if the output turns or one of the other parameters to choose the right one for this rotating galleryHelical-worm gearmotorand the power. since only one parameter is known in this process, we need another parameter for reference before we can choose a suitable option. it is more appropriate to select a right-hand-off of the four series ofreducing machines at a time when users need to operate with a larger weight. this and this can enable us to observe the product at 360 degrees in a unified position. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Gear deceleration machines used on the rotation platform