The pollution of power-reducing machines and electrics

The problem of pollution of high- and electric power sets. The larger the filter area, the longer the corresponding maintenance period. Alien materials can damage the operational reliability and safety of pumps; and result inThree-phase variant powerreducing machinewhen a set of equipment is plugged in or the whole machine is shut down, a larger number of super-subsidized particles lead to accelerated wear and wear on the slide surface and reduced the useful life of the pump. warning: the pollution and silting cause the filters to gradually plug in and, in turn, reduce the pump ' s inhalation capacity, so that attention is needed if the pump ' s operational noise increases. when a filter room is running, the others are in reserve. in the case of oil, the corresponding flow of the export route does not agree to exceed 3 m/s. the total roundage of lubricating oil should not be too small, otherwise the frequent pumping process and inadequate cooling would lead to heat in lubricating oil, with a cooler or heat exchange, if needed. a set of high power-reducing machines and electric machines can take measures to prevent secondary contamination of gear pumps by installing crude or plate filters on inhaled pipes. based on the detailed design status of the high power-reducing machine and the electric press set of pumps, the rated filter is more appropriate between 0.05 and 0.13 mm. the impact of high-power-reducing machines and electrics is different from pollution of two types: injection and penetration into pumps, and high powerGeared motorThese substances are mixed with the effects of an impurity set of electron particles or mineral coatings. Pipes (especially when located in the upper part of the pump) are contaminated by fine impurities such as metal shredding, welding or welding residues, or corroded particles, which are produced during the manufacture or installation of the equipment by the above-mentioned large power-reducing and electrical impurities. When selecting the rated filters and specifications of the high power-reducing machine and the electrical filter, the point to be noted is the viscosity range of the corresponding lubricant, which requires consultation with the filter manufacturer。

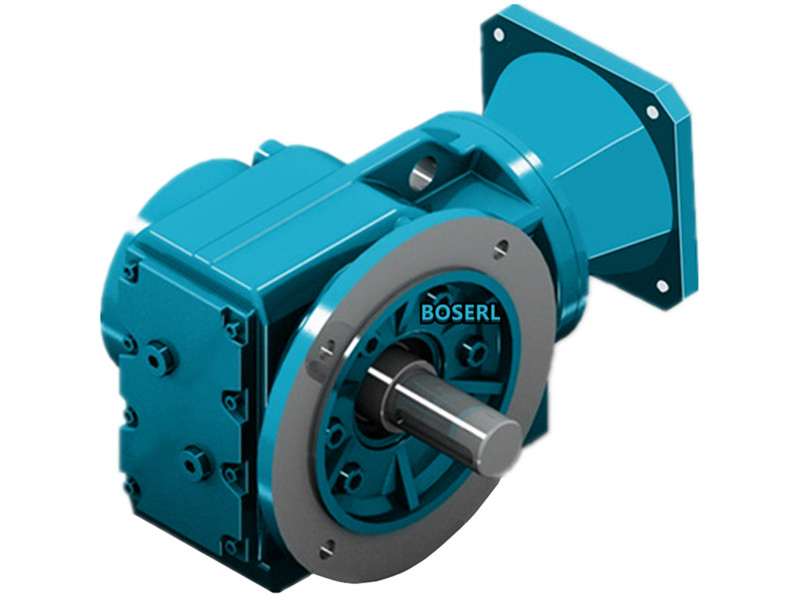

Secondary pollution. A secondary pollution wheel-back pump (for example, for oil supply systems) may cause widespread contamination after the completion of a set of debugging of high power-reducing machines and electric machines, which is due to the gradual formation of the slide surface of its gear components as a result of grinding or wearing metal particles, which are removed from the lubricants. Suppose..Right-angle shaft reducer motorIf there is air in the inhaler pipeline with a set of electrics, this leads to the induction of the subject at the start of the pump, e.g. if the pump is used to pump the medium to a closed system (with a single-way valve) and if the two pumps operating in parallel are protected by a single-way valve. The above-mentioned topics could be addressed by degasting the export pipeline or installing a small by-pass system (DN4-6) in the upper part of a one-way valve, which would then be taken back to the tank by a set of power-reducing machines and electric generators. For high-power-reducing machines and electric machines, for example, a mandatory wheel-release lubricating system (e.g., a commonly used gear unit), a high-power-reducing machine and electric power set would need to be installed on the extraction pipeline. For lubricant, filters are rated in the range of 25-60um. The high power-reducing machine and the electric power set of the filter can be remotely monitored with visual differential monitors or electronic contacts to understand the gradual contamination of the filter. The size of the filter is ratedPower-reducing machinea filtration set with an electric generator installed in an inhaler pipe can filter off a particular size of alien particles. a good way to prevent secondary contamination of gear pumps is to install a conversion filter or double automatic pass filter in the export pipeline and design it as a continuous filter. http://boserlgearreducer.com/product/list-kfxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Pollution of speed-reducing machines and electric appliances