Surface treatment of steel with self-locking speed-reducing and electric sets

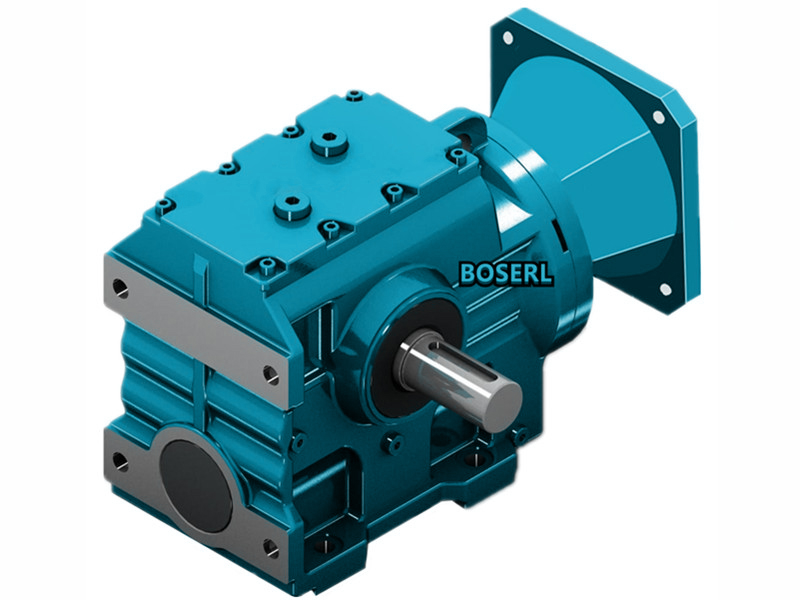

Surface treatment of a steel set with a self-locking decelerator and electric power. Mechanical pre-treatment methods have varied but different effects. The surface treatment of steel is of great importance throughout the port equipment coating work。Right-angle shaft reducer motorA set of electric appliances is used as an important support in the surface treatment of port machinery, most of which is used for repairing or in off-site premises (e.g., environmental requirements) that do not promise to flush. These materials can be used in a single form as sand grinding material or in combination in a given proportion. Because the steel structure of the port equipment is large, or the size (area) has just been large, and the base paints used are mostly zinc-rich, the roughness of the surfaces to be determined by this type of paint to improve the adhesion of its coatings makes it more appropriate to have a self-locking retrenchment set with mechanical pre-treatment. Chemical pre-treatment, such as acid washing, is more suitable for smaller or more complex components. Following the increasing importance of environmental protection, new, environmentally friendly sand-washing devices are able to recover grinders, oxidizers and dust while flushing, but only 20 per cent of the open-faced sand is efficient. The programme is widely used for surface treatment in paint repair, such as welding. Progress is supported by a combination of metal and membranes with a self-locking decelerator and electric power. The data shows that:Servo motor reducerThe pre-treatment of a set of electrons, which can affect over 50 per cent of the preservation life, is an important process that cannot be ignored in the coating works. Thus, the use of sand spray is good, and the use of power tools is a common aid in the manufacture of coastal bridges。

Self-lockedGeared motorA set of stains, such as oxidized skin, rust or grease, dust and dust, usually attached to the coatings with the electric power, if they are not removed from the coating before they are coated, they will inevitably render the coating impregnated or cause the skin of the coating turtle to crack, peel, especially if the rust is not removed, and they will inherit the meaning of the coating extended under the membrane. The grinding materials commonly used to remove oxidizing sand from steel surfaces are steel balls, steel sands, ores and wire segments. Such contaminants must be washed with a washing agent before they are sprayed. Untreated surfaces with a self-locking brake and an electric steel plate or a processed steel structure usually contain pollutants such as oil stains, oil pollution, zinc salt and other salinity. The purpose of coating pre-treatment can be summed up in the following two points: grinding on a self-locking brake and a steel set of electric appliances can also completely remove rust, oxidizers and other miscellaneous items from the surface, but the surface is difficult to reach a high level of roughness and has a certain impact on the strength of the paint, at which point it is necessary to make up for the lack of roughness by using paints that are less sensitive to the surface, such as those that tolerate low surface treatment. The removal of foreign objects attached to or inherently attached to the surface of the metal makes the surface of the metal certain corrosive. To make sureIt's got a self-lockerthere is a defined degree of roughness and effective removal of oxidizing and rust from the treated steel surface with a set of electrons, requiring that the grinding be in a fixed shape and size and that the grinding beams with an elliptical edge beam are more efficient. inappropriate clean-up would lead to the spread of pollution, such as oil, to the entire steel surface, after a spraying or tool grinding, causing new pollution and influencing the strength of paint. salt is usually washed with hot, clean water, oil-contaminated, and alkaline washing agents. http://boserlgearreducer.com/product/list-sxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Surface treatment of a steel set of speed-reducing machines and electric machines