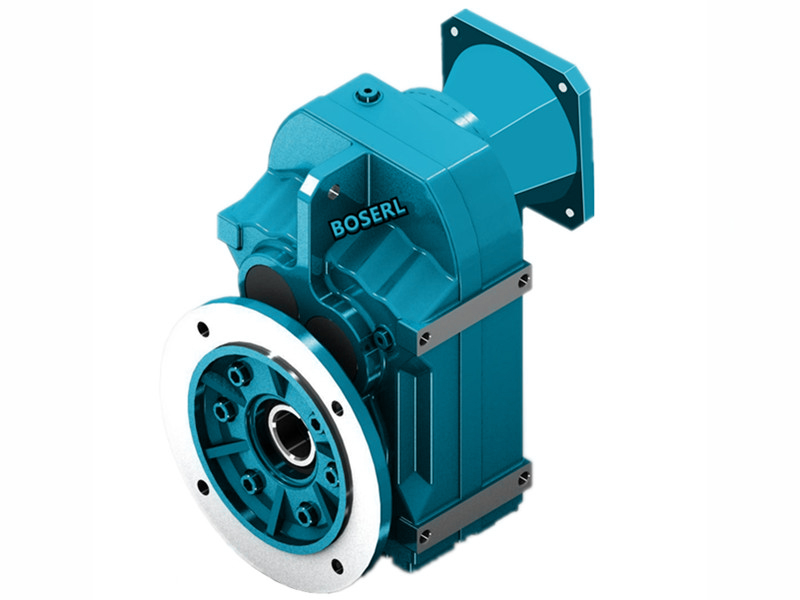

Inspection maintenance and lubrication of triple 220v speed-reducing machines

Inspection maintenance and lubrication of triple 220vreducing machines. Three-phase 220vreducing machines operated for one to two hours to ensure that too much oil from the interior of the bearings was squeezed out and, if there were any, shears were tightened. In general, when the rate of rotation is multiplied, it is necessary to shorten the corresponding lubrication cycle, which is about 40 per cent of the figure in the above-mentioned chart. press new lubricant fat into the bearing untilGearbocThe old grease is squeezed out; if the three-phase 220-v retrenchor is fitted with an export plug, it is unloaded; for machines with 180 specifications, the three-phase 220-v retrenchor usually carries a z or 27-type permanent lubricant bearing, the type of bearing is assigned to the respective product catalogue or to the label of each of the machines. In the event of an anomaly, the machine must be removed and the relevant parts checked and, if necessary, replaced. Check the condition of axle seals (e. G. , v-sealed rings) and, if necessary, replace the two hundred and twenty-two hundred and twenty-five-five-v reduction machines. Check the interface, assembly and bolt. If not possible, lubrication can be performed when the machine is shut down. If the machine has a lubricant tipboard, the three-phase 220v reduction machine must follow the assigned parameter values or otherwise the relevant values indicated in the chart below. At this point, only half-volume lubricant is injected, and the power is then operated at full and lasting for a few minutes. when the power stops, you can putDouble- power deceleratorThe remaining lubricant is pressurized until the old grease is replaced. In the secondary re-pricing process, all major lubricant producers can provide lubricant for the above-mentioned characteristics only with a special ball bearing lubricant that:

During the operation of the 3-to-220vreducing machine, it is possible to re-orient the power plant. The performance of the bearings is checked in the following ways, including listening to the sound, vibrations, bearing temperature, inspection of waste grease or monitoring of spm bearings. for a stand-up generator, a triple 220 vGeared motorRun hours are half of the above values. It is necessary to check the interoperability of the three-phase 220-V reduction vehicle bearings for high- operations. High values exceeding lubricant and bearing operating temperature are strictly prohibited. After 1 to 2 hours of operation, shea-export plugs, if any, are tightened. 16000-26000 load hours (for 2 polar and 2/4 polar machines (1)). Subject to an ambient temperature of 25C, the L1reducing machine of the tri-phase 220V has been assigned a good lubrication effect (direction only) of 32000-45000 load hours (for 4 polar machines (1)) during the following operating period. Temperature ranges from -30C to +120°C (continuing). Depending on their use and load status, reference can be made to the respective product catalogue. Base oil viscosity of 100-150 cST (subject to 40°C); 3 or NLGI2 or 3; lithium composite soap and minerals - or PAO oil lubricant; for use at a higher rate of rotation (e.g., a three-phase 220 V motor) or low- heavy load, a shorter lubrication cycle is required, with details to be consulted at the BOSERL sales office. For the automated lubrication system, it is necessary to unplug the grease export permanently. Re-(second) lubrication steps are as follows: inspections are required on scheduleThree-to-two-hundred-two-hundred-five-fiveMaintaining a three-phase 220Vreducing machine in a clean state and ensuring a good wind flow. Fewer times are used for machines with greater specifications. http://boserlgearreducer.com/product/list-fafxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Inspection maintenance and lubrication of speed-reducing machines