A coaxal slash gear reduction machine carries 44. 5 t-ton on the projectile

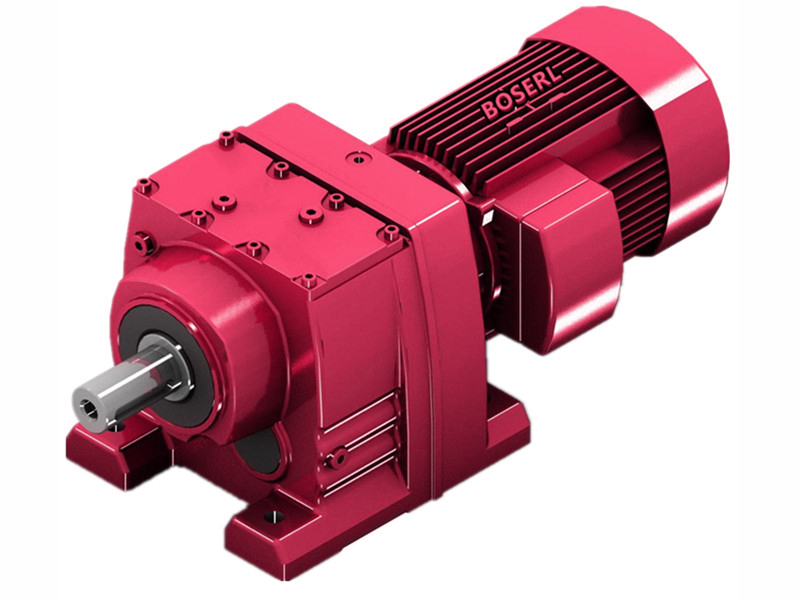

The axle oscillator is used to carry 44. 5 t-tons on the projectile. The user's projectile is a larger device, and the selected axle-slash gear-reducing machine will have to be operated with a device capable of driving 44. 5 tons of his motor, in which case it will have to match the corresponding axle-slash gear-reducing factor with the requirement. in addition, the device includes time relays set up in an electrical cabinet and used to change the projectile machineStand-by gear brakes(c) Frequency variants of working voltage frequencies and ranges. The user's projectile machine consists of a rack, a projectile clean-up room, a steel ball silo, a steel-ball promotion machine, a screwdriver, a work-loading system, a dust removal system, a dump and electrical control cabinet, and an axle axle gear reduction machine. During the projectile process, the wiring of the hook can be achieved by adjusting the said height, so that the project parts can be thrown towards the head on the different surfaces of the projectile clean-up room, and the projectile can be disposed of with a sharp tip. In a recent selection process, one of the users of the projectile machine thought about using the same-axis slash gear reduction machine to power his 44.5-ton device, and in that case what kind of power-reducing machine match would be more appropriate for the user's use requirements. See below some of the details of the use of the equipment and some of the parameters required by the coaxe slasher during the operation. During the production of the industry, the projectile projectile is a high- cleaning or strengthening of the casting surfaces by means of a spray device. Time relays are used to control the time of the projectile disposal, and the trans-frequency is used to control the axle turrets of the projectileGeared motorThe is used to control the size of the projectile so that the suitable projectile strength is selected for the different work surfaces。

The work-loading system consists of a hook component and a hook-walking device, a hook-walking device consisting of a hook, a hook-to-heavy wiring bar, a motor, a hook-walking device to drive the hook component above the projectile clean-up room, a power-driven electric generator and an axle gear-discharger to rotate the hook, and a hook-laying unit to rotate into the projectile clean-up room. The projectile machine strikes the surface of the metal by one or more sands, removes some attachments to the surface of the metal, such as rust, or acquires a particular surface layer by projectile impact. The use requirement for top users of the user selection process is the useGearbocWhen power sets are installed to drive 44. 5 tons of projectiles, and in such a case there are not too many constraints to select the corresponding axle gear-reducing machine type, let's look at some of the basic features of the equipment and some of the things that should be noticed in the selection of a coxle-slash-reducing machine. This is the structure and operation of some of the equipment of the user, in which case we are not aware of some of the parameters required for the operation of the equipment, so it is not easy to choose the corresponding device, as in the case of the axle gear-reducing model and the matching of the axle gear-reducing functional parameters. The projectile medium may be sand of various specifications, carbide silicon particles, steel balls, etc. if you don't know how many models you're choosing to use in your selection, you can consult the boserl-axis slasher technical staff to make the choice you wantMotor gearedthe model matches the powered engine and the corresponding functional parameters. the metal-processing patterns between different devices during some metal-processing processes are different, as are the treatment processes and the mechanical equipment required for treatment of different subjects, so in the selection process, a matching device is selected to be used, taking into account the actual circumstances. http://boserlgearreducer.com/product/list-tongzhoujiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: A co-axis slasher is used in a ball projector