How do you choose to use the power-reducing unit to drive more than 100 pounds of weight in the delivery equipment?

How do you choose to use one-size-fits-all power-reducing machines to drive more than 100 pounds of load in the delivery equipmentInduction Motor 3PhIs it possible to meet the requirements of a given use? Use this user selection case below to see how the selection process is. After confirmation with the user, the user's conveyor belt is smoothed, so in this case we can make a preliminary determination of the size of the twist. When the user selects this type of device, it is necessary to understand the parameters of the equipment clearly, and the selection will become simpler. In the user selection process, the user has a clear request for loads, so in this case, whichreducing machine should we choose to use? The user does not explicitly require the use of snail snails or slash gears, so it is sufficient to satisfy the user ' s installation needs. Of course, it would be more cost-effective to choose to use smalldown opportunities in cases where the load is as small as that of the user and the value for money is higher. There are relatively large differences between the various devices used in different equipment, so in this case we need to consider the actual usage, see what the parameters of the equipment should be, and then choose the corresponding power drive. All we have to do is choose a half-twirl, and then the range of output-twirl of an umbrella gear-reducing machine is around 50 to 70 nm to drive more than 100 pounds of equipment. so there are so manyGeared motorWhichreducing model can be used in the conveyor belt? At this point, it is important to look at the detailed selection of parameters to determine whichreducing machine to match。

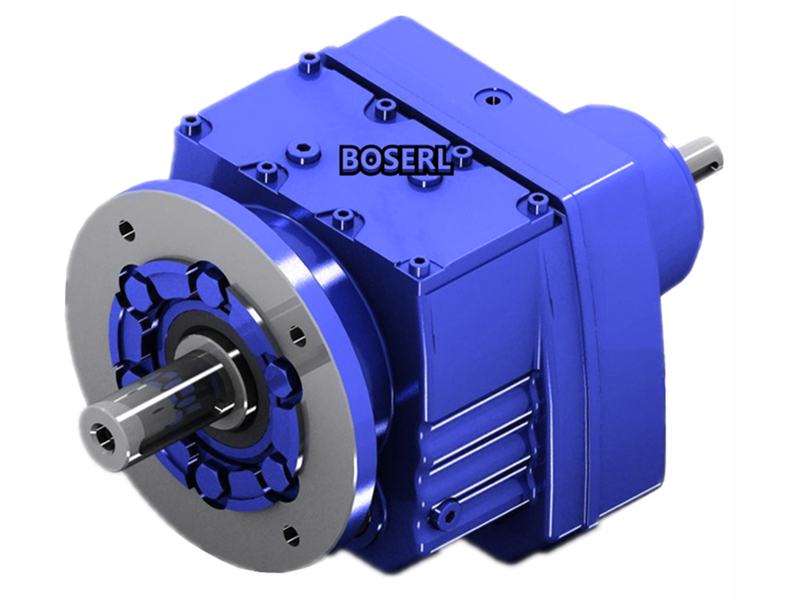

He needs to design a conveyor belt with a load of more than 100 poundsReducer+MotorI don't know. How many loads should be selected for use at a time when the user's load is over 100 pounds? We need to know about the operation of the equipment first, because some of the conveyor belts operate in a tilt. , others in a smooth transport, and different modes of operation have an impact on the selection of the output twists of the power-reducing unit, so when you select, you will consider the actual operation to better select the equivalent of the gear-reducing machine, which is still the scalder. In this case, we also need to determine the parameter, which is how much is going to run, at which point we can consider the length of the roller-axis diameter on the conveyor belt and in which case we can calculate the detailed between formulas. Different units of different users require different types of motor-reducing machines to be selected, so you can ask us to use b0serl-reducing machine technicians to help you with your equipment parameters. When a user made a conveyor belt device in the recent past, there was a greater degree of customization in the design because different users had different requirements, particularly load and, in the design of the conveyor belt. so in this case, we could choose to use a smallerreducing machine, like a snail snail, a tkmRight-angle shaft reducer motor, TRC hard-toe brakes, rectangular axle brakes, or smaller-sized brakes in the four series. http://boserlgearreducer.com/product/list-rxxilijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Power-reducing unit for transmission equipment