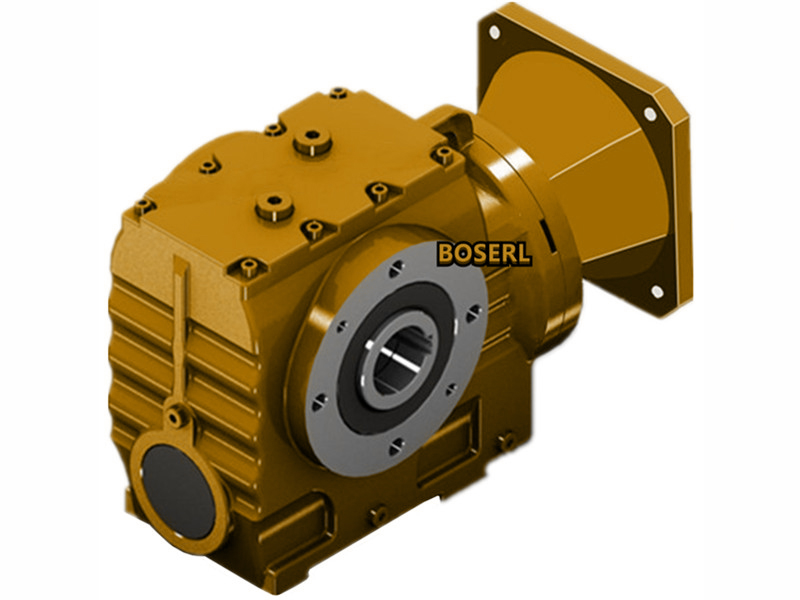

Double-guided snail retrenchor for high-precision automation

A double-guided snail retrenchor matching a machine for high-precision automation equipment. if you don't know how to select or match thisreducing machine, you can consult b0serl directlyGeared motorThe technologists ask them about the snail brakes in the small snails, and then tell them your parameters, and let the technologists match you with the details of the model and the parameters. The equipment requirements were identified through a number of long-duration studies and in-depth workshops, the selection of layers, the selection of snail snails suitable for grinding, and the restructuring of the back produced the current small snail agile. It's simple to say that the four-degree power is better positioned. At the beginning of the month, a user ' s high-precision automation equipment required a snail snail-reducing machine with as small a gap as possible, matching other devices of the equipment with a reduction distance. If such a function is to be achieved, it will often require the interaction of the entire machinery during its operation. They act as hubs as transmissions and power drivers. Whether the gear-reducing machine is a snail-reducing machine or not, the output velocity may affect the productivity of the production of equipment products. So when used, the electrics are matched for matching, and when the electrics are selected, the electrics are often selected to match _ on the reduction machine. And what kind ofreducing machine would he wantServo motor reducerWhat do you need to look at when you match?

Today, in this user's case, let's see what the demand is when it's chosenHorizontal reducerIt's optional. With this small snail snail, thereducing machine is only a requirement that allows for the control of the output retrenchment accuracy, and the need for positioning and other requirements is not currently being met, which is theretard. Moreover, the gap in thisreducing machine is relatively fixed, and the longer it is used, not like a snail snail, the greater the gap. In such a case, the equipment ' s requirements forreducing breaks can be met by using high-precision automation equipment. Over a long period of time, the of output of the brakes has changed from the original comparison because of internal wear and tear or because of external irresistible reasons. The user chooses to use a no-space snail snail to slow the engine because it is intended that the small load equipment will not be used at a general rate of change. If you have been paying attention to the b0serlreducing machine for a long time, you should know what the difference is between the electric power and the three-step machine. This small snail-deep snail-drunker, which happens to be a b0serlreducing machine, is able to satisfy such a requirement. used on different equipmentThree-phase variant powerreducing machinethere will be different usage requirements, and different equipment will have different precision requirements on the equipment because of different operational accuracy requirements. accompanying the continued sophistication of the automation equipment, an increasing number of the equipment will require some precision at the time of its use, as if it could be precisely positioned for manipulation at a certain location. http://boserlgearreducer.com/product/list-wolunwomenjiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Double-guided snail brakes without a small back gap