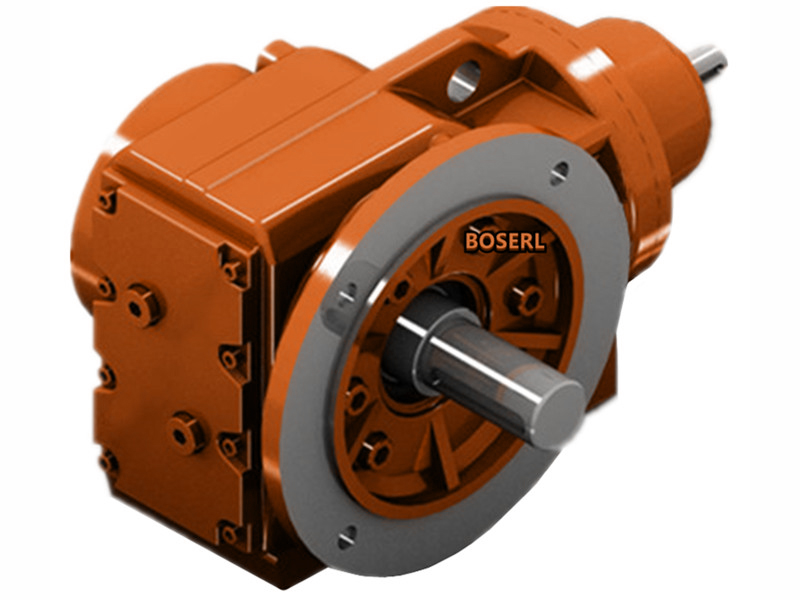

A hyperbolic decelerator assembly line

A hyperbolic reduction machine assembly line. The umbrella co-axis slash gear reduction gear total assembly line is at an internal lead level, but there are defined gaps in comparison with external products. YeahSpiral cone gear deceleratorThe assembly liner was analysed and different components were created, providing a method for the modular configuration of the assembly liner. This will provide us with a theoretical and practical guide for future major car assembly lines. It occupies an important position, so that the quality of the assembly of the mainretarders of progress is of great concern to automobile companies. Pro/E provides users with a rich secondary development tool. Simulates the influence of the stress field, deformation, and the frequency inherent in the first steps of the resize of the hub parameters. An umbrella-axis slash gear-reducing machine modularization can change the core size of the assembly line so that it can adapt to the assembly of different parts and measure some of them, thus simplifying the study of the subject matter and more in line with the idea of a hyperbolicreducing machine modularization. The car's main brake is a part of the car's undercarriage hub, which is directly related to the whole of the vehicle's motor, and which is of good quality and bad quality, directly affecting the hyperbolic sideGeared motorThe smoothness of operations, noise, lifetime and energy consumption. However, because of time constraints and limited personal capacity, there are many outstanding topics that need to be further researched and explored in future research。

The Pro/E-based robotic parts library parameterization design is based on the secondary development system of the Pro/E platform, which is the core of the equipment parts parameterization design system, which provides applications that greatly improves the mapping efficiency of the parts and achieves the rapid construction and re-construction of the mechanical parts of the hyperbolic decelerator. Optimizing the goal of progressive assembly line-lined kinetics, good structural parameters of the line have been derived, providing a sound theoretical basis for the design and construction of a hyperbolic reduction machine assembly line. Family names are more appropriate than other development toolsRight-angle shaft reducer motorThe creation of modularization of assembly maps is also convenient and compatible with the learning of mechanical professionals. On the basis of the theoretical analysis, the pivotal parameters of the umbrella coaxial oscillating gear reduction unit assembly line bodies were analysed and a limited meta-analysis of its application of ansys software was performed under the single factor method and the positive test method. Therefore, it is necessary to refine and optimize the overall assembly line of the main brake. Since the assembly line is a multi-species assembly line, the analysis gives more consideration to the effect of the smooth sequencing model of the water flow line balance and the traditional smooth sequencing model of the mixed assembly line on the alignment of the assembly line, with a view to optimizing the ranking of the good product input. even then, the modularization of each of the spare parts in the hyperbolicdown machine assembly plan is a much larger task。

2 A parametric design model for the paralysing of lined bodies with paralysing and oscillating gears was developed using the Pro/E software, which enables the creation of a model library of assembly lined bodies with different parameters, and the call of the design staff for the hyperbolicdiggle assembly lined bodies. Specific analysis of the design process of the assembly line layout was carried out and the main equipment structural features and functions of the assembly line were pre-empted. And, of course, we can create a family watch for some of its scale partsMotor gearedthe total assembly is added in the same way as the other parts above are created. with an understanding of the current state of the design and development of the condensed assembly line, the differential cycling process for the mainreducing unit of the hyperbolicreducing machine was analysed in the form of a mixed flow-relaying assembly line, from which two umbrella and axle gear-reducing machines were selected, and from which a better balance was chosen. the following conclusion was reached: the type and mode of transport of the overall reduction assembly line for the umbrella-axis slash gear reduction unit and its detailed application in the overall mixed-flow assembly line for the car main brake. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed reduction machine assembly line