Obstruction of the brake bearing of a standing gear

(b) The failure of the axle bearings of a standing gear brake. Axle bearings, which are the main basic components of a standing gear brake, have small friction resistance, and the advantages of assembly and ease of lubrication, and are used in a wide variety of gear brakes. During high- rotations, as a result of the multiple and repeated effects of the huge trajectories, the metallic surfaces of the bearings produce fatigue, detachment and formation of small puddles. The traverse stress caused by the load is the main cause of detachment, which is secondary to lubrication or forced installation. Wearyness on the moving bearingsStand-by gear brakesThe other form of failure of the axle bearings is often manifested in the debilitation of the surface of the oscillator or roller, which initially forms an irregular puddle on the surface, then gradually extends into a piece, and when the axle bearings are working, they have a high exposure due to the small area of contact with the inner and inner circle。

The monitoring and diagnosis of the kinetic bearings is an important element of a stand-by gear-retarder failure diagnostic technique because of inappropriate design, poor processing or installation, poor working conditions such as lubrication, impact loads, etc., which causes various defects in the kinetic bearings to occur after a period of operation, andMotor gearedIn the course of the succession, the defects will also be extended, with the deterioration of the dynamic bearing resulting in total failure, with the loss of the gear-reducing electrical motor bearings in the form of wear and tear, stripping, pressure marks and adhesion, etc., and the breakdown of the dynamic bearings in large parts of the unit can be reduced to surface deterioration, thus exacerbating the vibration. This is mainly due to inadequate assembly, and may sometimes be due to overload or impact. Its vibration feature is the presence of an impact pulse in the vibration signal, which changes the average, range and high-level rectangular of the signal, and in the frequency field, the high-frequency composition of the signal increases significantly and changes in its energy distribution. The presence of grinding material is the basic cause of wear and tear on the axle bearings of a standing gear reduction vehicle, which has experienced a long history of wear and tear and is a gradual failure. Axle bearings are active because they are affected by, inter alia, load, installation, lubrication, etc., and will be extended over timebrakes motor-reducerIt's a weak link。

The wear-out effect of the brake bearings: This is a common form of failure, a rolling, moving bullet in a vertical gear-reducing bearing, maintenance of a frame, a hole or an axle neck with bearings, a surface wear caused by mechanical reasons or lubricating impurities, which, in the harsh working environment, can be mixed into lubricating oils, enter the gear-reducing electric bearings, thus causing grinding on the moving bullet and the roller, and spreading uneven marks on the moving bullet and the roller. Vibration following wear and tear of the bearing surface is of the same nature as diagnosis of the normal bearing and is more random, but the value of post-brand vibration is significantly higher than the normal bearing. Broken bearings of the moving bullet bearings: Breaks and fractures of the bearing parts are mainly caused by upmilling or thermal processing, or by standing gearsGeared motoroperating time loads are too large, revolving too high, lubricating or poorly assembled, resulting in a localized stress concentration of a component of the bearing, creating cracks and fractures. the pressure marks of the moving bearings are not working: they are created by the puddles of the gear-reducing engine bearings overloading, impacting or entry of foreign objects into the rolling circuit, resulting in local deformation on the surface of the moving bullet or roller. http://boserlgearreducer.com/product/list-rfxiliijiansuji-cn.html

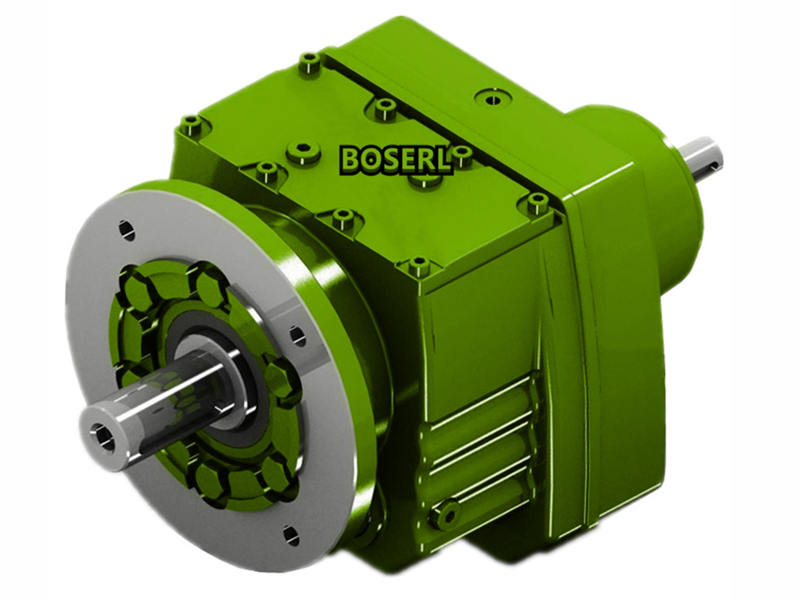

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: We're losing the brake bearing