Method for cycling and lubricating the parts of the axle bearings of the umbrella gears

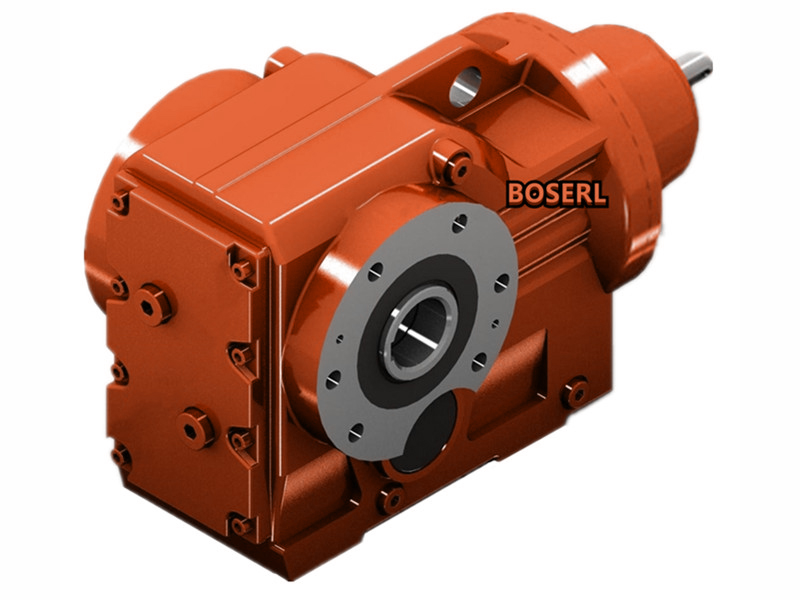

Method for cycling of turbo-patron bearings with lubricant. The embedding of the axle bearings of an umbrella wheel is a very important and frequent element of work, but the series of factors, such as heavy production, which has led to the omission of lubricating oil in a quantitative oil storage cup, has resulted in the wear of the axle bearings of an umbrella wheel because of the lack of oil, severely affecting the safety and balance of its useful life and operation, in particular the need to replace the axle bearings and their attachments with a high degree of work and maintenance, as well as a long period of repair, thus seriously hindering and delaying the orderly conduct of the production。Low-turn reduction machineIt is a relatively sophisticated power-transmitters orchangers, which use gear gears to reduce the number of circuits to the desired number, as well as to obtain a larger retrenchment. The gear-retardors are used in a wide range of applications and are visible in almost all types of machinery's transmission systems, from ships, cars, locomotives, heavy machinery for construction, processors for the mechanical industry and automated production equipment. We can re-use the principles of the connector to get the lubricating oil through the pipelines and the oil volume control valves into the bearings that require the lubricating oil, and re-loading the lubricating lubricating bearings of the paratroopers. We can connect the collection boxes with the bearing parts that need to be injected with lubricating oil, so that the lubricant in the collection boxes is bound to flow to the direction of the axle bearings of the paralytic gear, based on the principle of the connection. Its applications range from high power to small loads, which can be seen from a precise angleBig load retarderIn its application, and in its industrial application, the gear-reducing power plant has a reduced and increased rectangular function, so it is widely used forreverse conversion equipment, bearings are an important component of an umbrella gear-reducing machine. In the previous chapter, the sub-editor described the new concept of the gear-reducing power-receiving unit as a fuel supply, and this section will describe the method for the automatic reloading of lubricating oil on the wheel-receiving gear-receiving unit。

If the collection tank is slightly higher than the bearing parts that require lubricating, then the lubricating oil in the collection tank is affected by the rotation of gears and the spilling of lubricants, the amount of oil stored increases, and the same environment on the surface of the connector is broken, and the gears are then brokenGeared motorThe lubricant in the bearing component endpipe will spill into the bearing component, and when the source of lubricant from the revolving gear-reducing engine gushes into the collection tank, the lubricant in the bearing component endpiece will also spill over into the bearing component, thus enabling the refilling of the lubricant. In view of the sufficient and large amount of lubricant oil in the collection tanks and the limited amount of lubricant oil required to be injected into the bearings of the gear-reducing motors, and in order for the lubricating oil to reach an accurate level of equity in the amount of oil in the bearings, it is necessary to set up a volume control valve at the end of the piping of the axial parts, which will be effectively measured in accordance with the demand for the lubricating oils in order to achieve accuracy and equity in the volume control. WhereasAn umbrella gear-reducing machineduring the rotation of gears, some mechanical impurities arising from high pressure frictions between gears and gears, metal grinding, etc., have been half-way to the pipelines with sediment tank installations, and the collected lubricant is filtered through the initial filtration net, as the lubricant still contains small iron dust powder, which, when deposited through the sedimentation, will be fully deposited within the bottom of the sediment tank, thus ensuring that the lubricating oil entering the bearings is clean and clean. according to the principles of the connector: two or more containers connected below the liquid surface are equal when they contain the same liquid and the same pressure on the liquid surface. http://boserlgearreducer.com/product/list-zhiajiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Method for recycler bearings of slow-down machines with lubricants