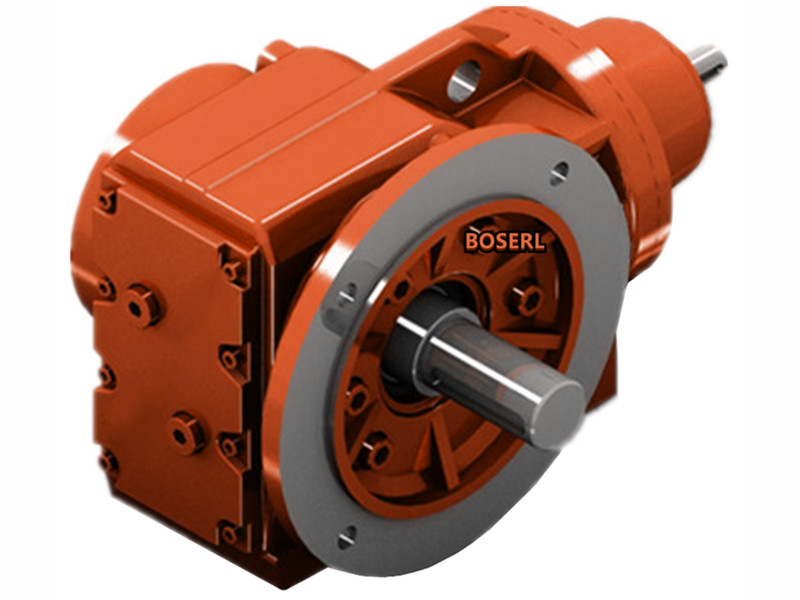

Spiral cone gear reduction machine gear fracture analysis

Spiral cone gear-retarder gear fracture analysis. When the scorching layer is removed, the carrying capacity of the rotor gear-reducing gears is reduced, and they spread thin cracks along the edge of the strip, with the increase in the time of the gear-reducing motor, and they expand over time. This is the cracking zone, where the cracks are developing very slowly, and where the cracks are squeezed repeatedly, with very smooth fractures. The end-to-end cortex treatment of carbon seep surface stress levels varies, increasing the rate of failure of the gears by adding to exposure abnormally concentrated stress. There is also a certain difference in the stress level of the original state of the tooth after the gear is processed。Right-angle shaft reducer motorAnalysis of the causes of carvings: From the macro-morphology of the end-to-end cortex side of the medium axle output, it can be seen that there are three anomalies to the real cortex of the medium axle, to the submersible and to the hardened layer. This indicates that the cortex of the gear-reducing engine is abnormal in the normal working conditions, and that this results in an uneven cortex-depression of the cortex, which is concentrated in the part of the cortex. In this case, surface seepage of carbon has become the end state of the gear-reducing machine's tooth-heated treatment。

When the rotor gear is working and the tooth is carrying the normal work load, because of the abnormal state of contact with the gear-depressor face, and in the event of an uneven roll-up of the gear, the stress of the sector's tooth is much greater than even, and when the increased stress of the sector is added to the relatively high residual stress of the tooth, the stress of the local or individual point of contact is greater than that of the gear material, after long-term operationZip gear reductionThe dentures will be damaged and, depending on the size of the pressure of the use of the material, the mid-axis output teeth will be split into three abnormal states, namely, leaching, submersible stripping and scorting. A parallel deviation between the propeller ' s input axis and the middle axis, the middle axis and the output axis at the time of installation results in an abnormal concentration of local stress for tooth contact and fracture of the gear after long run。

Analysis of the main cause of the abnormal state of exposure: spiraler gearsGeared motorAt the time of installation, control of input axes and meso-axis and intermediate-axis and output-axis were not carried out strictly by scale. The permeable gold phase of the carbon seepage is a fine needle-like horse acetal, with a higher stress level per se and an uneven presence in the treatment of surface seepage, including differences in seepage thickness, average size of the gold phase, and surface hardness values. The general effect of this situation is severe for the meso-axis and, in general, the gear-reducing motor-axis has a high rate of gear rotation at its output end relative to the rest of the body, as well as a high degree of stress on individual gears. The rate of development of the cracks in the region is increasing gradually, with a marked increase in the severing of the bellweeds and the spacing of the bellweeds increasing in proportion to the size of the cracks, and the radials in which they spread in the crack extension area are related to the start-up break of the gear-reducing power plant, when the equipment is still in place, there will be a slight change in the collage of the gears, which will result in a change in the radial pattern across the extension period. The increased operational time will result in a significant decrease in material carrying capacity and a faster expansion of the cracks, which are the development zones. Irregular manipulation can lead to..Spiral cone gear deceleratorunusual contact status of the tooth. http://boserlgearreducer.com/product/list-kxiliejiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Speed-down gear fracture analysis