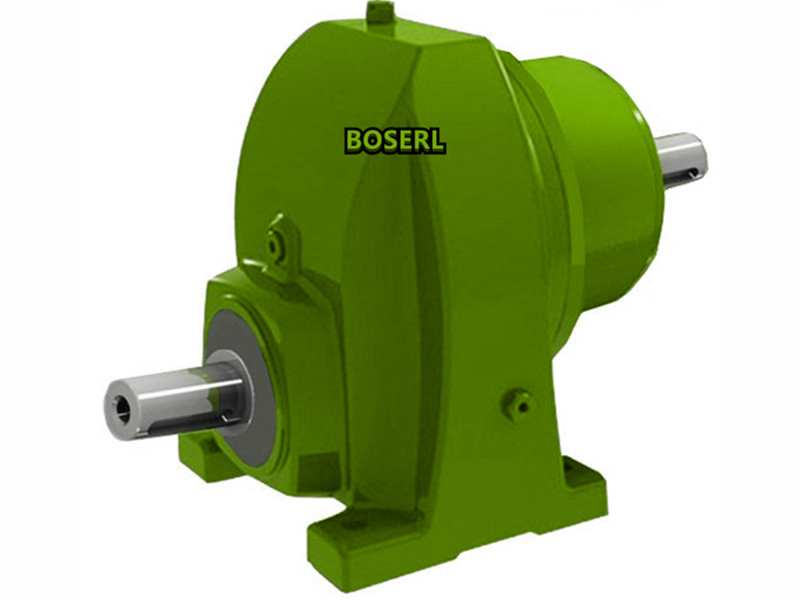

Design elements for the details in the gear-reducing machine

Elements for the design of the details in the gear-reducing machine. The rigging should not be installed at too low a level, otherwise the fluid would spill. The parts on the axis shall have a co-ordinated segment with a positioning requirement, which shall allow the rim to have a width greater than the length of the axle in which it is accompanied by a length of 1-3 mm. In the design of the gear-reducing motor, a bolt is used to connect the hood and the cones of the seat, as well as the upper and lower bearings, using a normal bolt link, with a gap between the bolt hole and the bolt pole. In the last chapter, it's trueMotor gearedThe most common topics in the design have been elaborated, and in this section, it will be possible to improve the way in which the various components of the design can easily occur. Arrays are simple in structure and are more used on top of the gear-reducing motor, with the last two ciphers indicating high and low surfaces, respectively. Attention should also be paid here to the position of the oil coordinates to facilitate the processing of the headlines and drilling of the wire, as well as to the handling of the junctions. The hood and seat of the gear-reducing motor are found in a casting, and the bolts shall be constructed into a sink seat or a condensation to ensure that they are supported to level and that, when installed from the bottom to the top, the bolts shall be smaller than the distance between the lower bearing of the seat and the bottom cone。

When the axle surface needs to be sharpened or snailed, a sand-wheeling or screwdriver chute is required to remain at the axis change. In case of lipid lubrication, the lubricant is immersed in thin lubricated lubricated lubricant near the side of the carpentry, and when the product is produced in bulk, the pressure-pressure ring is used for the gearGeared motorA distance of 10-15 mm between the internal side of the bearing and the wall line in the case, and when oil is used to lubricate, the oil conductor in the wall of the turbostat tank flows into the tank ' s sub-cutter (a multi-processor-processed oil ditch) and lubricates the bearing in the bearing. At this point, the distance between the inner side of the bearing and the wall line inside the box is three to five mm; when the change in the axis is for the fixed part, the change in the adjacent diameter is 8 to 10 mm, and when the change in the axis is for the assembly and/or for the processing surface, the change in the diameter is recommended to be one to three mm or even different from the diameter。

To facilitate the removal of the lids, a bolt bolt is placed on the top of the lids of the gear-reducing motor. The oil hole is normally sealed with a screw and the diameter of the plug is 1.5 - 2 times the thickness of the wall. When there are multiple key slots on the same axis, the key is positioned to facilitate the processing of the key slot on the axis. The cones shall have a cam, which shall be sealed between the bolt and the condensed cone. For that reasonGear reducer and gearboxThere is a gap in the bearing cover, which may be smaller in diameter in order to prevent a gap in assembly from being blocked in the oil ditch. In order to facilitate drilling and laceration, the bottom of the motor seat is reduced by gears with pits in the oil hole. When the fermentation wheel is rounded at not more than 2 m/s, the axle bearings of the rectangular gear decelerationer are lubricated, otherwise oil lubricated. The oil labels are used to indicate the height of the oil surface of the gear-reducing motor, which should be located in a location that facilitates inspection and is not disturbed. A bolt diameter of the same length as a skeletal cam link bolt, with a length greater than the thickness of the cam of the scaffold, with the end of the snail being cylindrical or hemispheric in order to avoid damage to the snail; the oil vent should be located at the lower end of the seat of the recoiler, at the bottom of the rectangular seat of the recoil, on the lower side, in the direction of the one-100 slant, to facilitate the release of the oil. Keys slots should be placed close to the input end of the parts on the axis so as to match the key slots with the keys on the rim at the time of assembly and the length of the key slots is 5-10 mm short of the length of the axis. WhenZip gear reductionwhen the axis is fitted with a measure, such as a moving bearing, the axis neck is to take a measure value, which is to be disassembled for the stem bearing, and the position of the axis shoulder is to be lower than the outer diameter of the inner bearing of the axis. http://boserlgearreducer.com/product/list-rxiliijiansuji-cn.html

Keywords: Bevel Gear Reducer Selection_Hardened Gear Surface Reducer Motor Selection_Helical Gear Reducer Selection_Bevel Gear Reducer Selection_Worm Gear Servo Motor and Reducer Selection

标签: Design elements for the details in the speed-reducing machine